At its core, a PTFE gasket provides an unparalleled combination of chemical inertness and temperature resistance. Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is a high-performance fluoropolymer prized for its ability to create a reliable seal in demanding environments. Its key benefits are near-universal chemical resistance against acids, bases, and solvents; a very wide operational temperature range; and non-stick properties that prevent process buildup.

The decision to use a PTFE gasket is driven by the need for extreme chemical or temperature resilience. While its core properties are exceptional, understanding its primary limitation—the tendency to "creep" under pressure—is critical to selecting the right variant for your specific application.

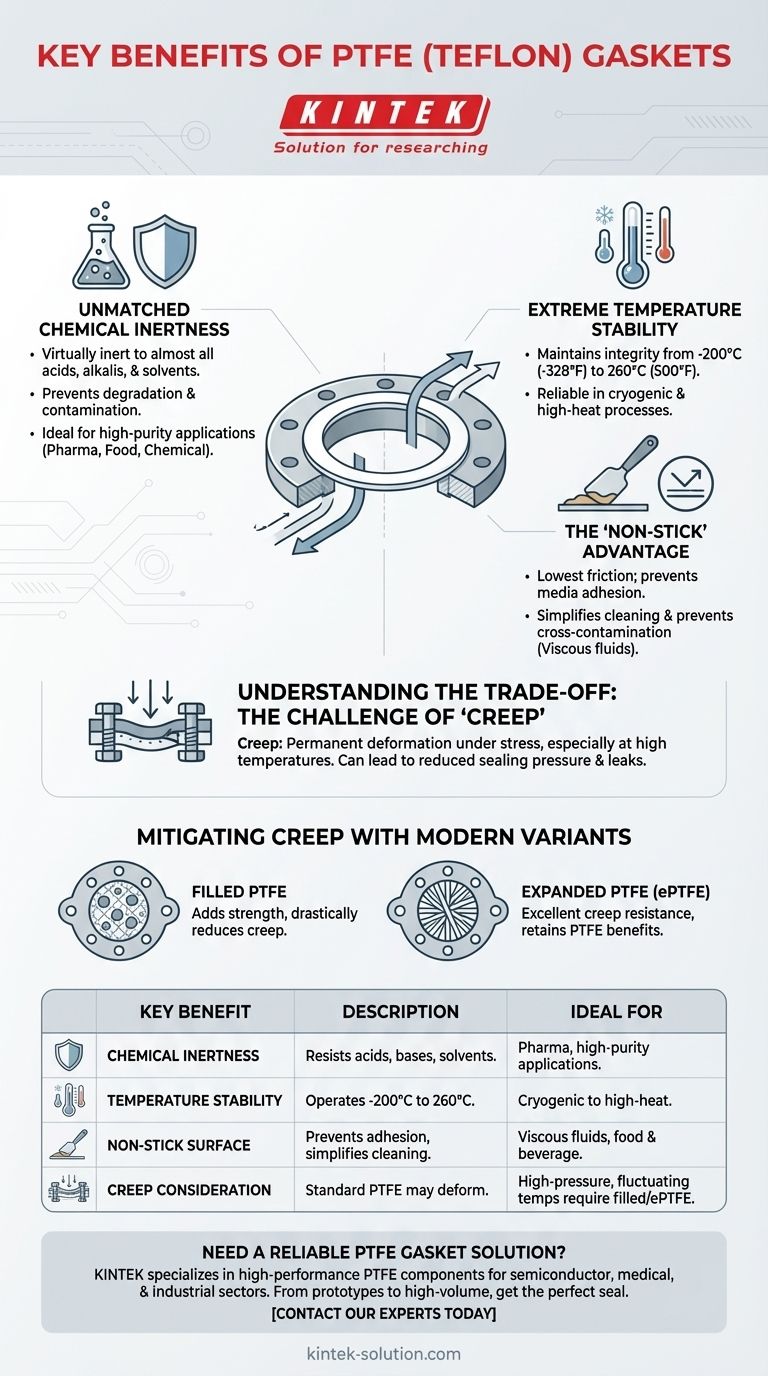

The Defining Properties of PTFE Gaskets

PTFE's unique molecular structure gives it a set of characteristics that make it a default choice for many critical sealing applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including the most aggressive acids, alkalis, and solvents.

This ensures the gasket will not degrade or contaminate the process fluid, making it essential for high-purity applications in pharmaceuticals, food and beverage, and chemical processing.

Extreme Temperature Stability

PTFE gaskets maintain their integrity and sealing capability across an exceptionally broad temperature range.

They can operate effectively in cryogenic conditions as low as -200°C (-328°F) and in high-heat processes up to 260°C (500°F), providing a reliable seal where other materials would fail.

The 'Non-Stick' Advantage

PTFE has one of the lowest coefficients of friction of any solid material, giving it excellent non-stick properties.

This prevents process media from adhering to the gasket surface, which simplifies cleaning, prevents cross-contamination, and ensures consistent performance in applications with viscous or sticky fluids.

Superior Conformability and Sealing

Virgin PTFE is a soft, flexible material that can easily conform to surface irregularities on a flange.

This high compressibility allows it to create a tight, effective seal even on surfaces that are not perfectly flat, preventing gas and liquid leakage.

Inherent Purity and Durability

PTFE is inherently pure and contains no contaminants that can leach into the process media, allowing for FDA-compliant options.

Furthermore, it is resistant to UV radiation, oxidation, and corrosion, and does not age or become brittle over time, contributing to a long service life.

Understanding the Trade-offs: The Challenge of 'Creep'

No material is perfect, and for PTFE, its primary limitation is a mechanical property known as creep. Objectivity requires acknowledging this trade-off.

What is Creep (Cold Flow)?

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

For a standard PTFE gasket, the pressure exerted by flange bolts can cause the material to slowly "flow" or squeeze out from between the flanges over time, especially at elevated temperatures.

Why Creep Matters

This deformation can lead to a loss of bolt torque and a reduction in sealing pressure.

Eventually, this can compromise the integrity of the seal, resulting in leaks. This makes pure, unfilled PTFE unsuitable for many high-pressure or fluctuating temperature applications.

Mitigating Creep with Modern Variants

Engineers have solved this problem by creating modified versions of PTFE.

Filled PTFE adds materials like glass or graphite to the matrix to improve mechanical strength and drastically reduce creep. Expanded PTFE (ePTFE) has a multi-directional fibrous structure that provides excellent creep resistance while retaining PTFE's other benefits.

Making the Right Choice for Your Application

Selecting the correct gasket is about matching the material's properties to the system's demands.

- If your primary focus is chemical compatibility and purity: Standard PTFE is an excellent choice for sealing against aggressive media in food, pharma, or lab environments where pressures are moderate.

- If your primary focus is sealing in high-pressure or fluctuating temperature systems: You must specify a filled or expanded PTFE (ePTFE) gasket to mitigate the risk of creep and ensure a long-term, reliable seal.

- If you are sealing irregular or damaged flange surfaces: The superior compressibility and creep resistance of expanded PTFE (ePTFE) make it the ideal choice for creating a tight, durable seal.

Understanding these core properties and limitations empowers you to select the precise PTFE gasket that ensures both safety and performance.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents. | Pharma, chemical processing, high-purity applications. |

| Temperature Stability | Operates from -200°C to 260°C (-328°F to 500°F). | Cryogenic to high-heat processes. |

| Non-Stick Surface | Prevents media adhesion and simplifies cleaning. | Viscous fluids, food & beverage, preventing contamination. |

| Creep Consideration | Standard PTFE can deform under pressure; filled/ePTFE variants solve this. | High-pressure or fluctuating temperature systems require modified PTFE. |

Need a reliable PTFE gasket solution for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets for the semiconductor, medical, laboratory, and industrial sectors. Whether you need the extreme chemical resistance of virgin PTFE or the enhanced creep resistance of filled or expanded PTFE (ePTFE) for high-pressure systems, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the perfect seal for your demanding environment.

Contact our experts today to discuss your specific requirements and get a solution that guarantees safety and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications