There is no single "typical lifespan" for a PTFE rotary shaft seal. The longevity of these components is not a fixed time period but is entirely dictated by the specific conditions of their application. A seal's service life is a direct outcome of the interplay between its material composition, design, and the operational stresses it endures.

The core principle to understand is that a seal's lifespan is an engineered outcome, not a predetermined specification. Maximizing it depends on correctly matching the specific PTFE compound and seal design to the application's unique combination of speed, temperature, pressure, and media.

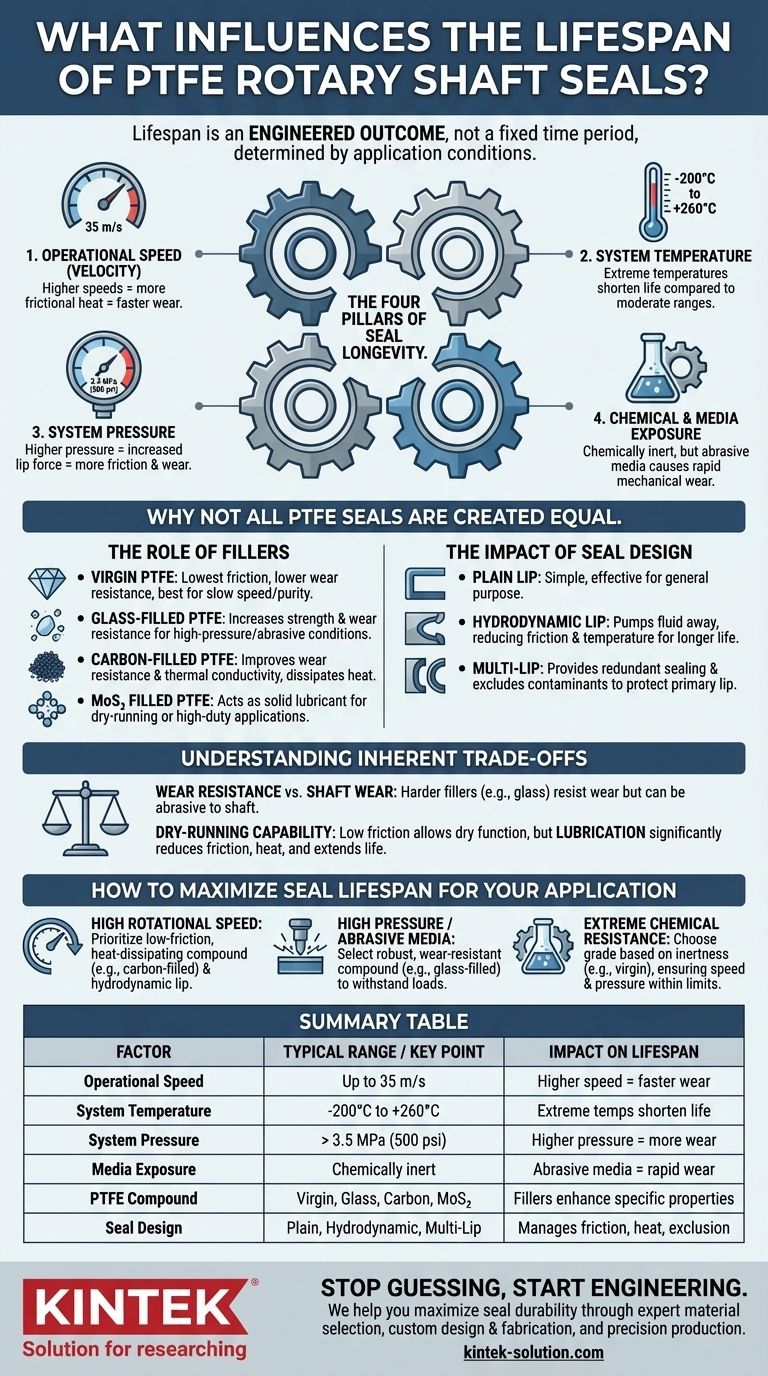

The Four Pillars of Seal Longevity

The service life of a PTFE rotary shaft seal is governed by four primary operational factors. Understanding how your application performs against these benchmarks is the first step in estimating and maximizing seal life.

1. Operational Speed (Velocity)

PTFE seals are renowned for their ability to handle high rotational speeds, often up to 35 m/s (meters per second). However, higher speeds generate more frictional heat at the contact point between the seal lip and the shaft. This heat is the primary driver of material degradation and wear over time.

2. System Temperature

The material itself has an exceptionally wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F). While this demonstrates the material's stability, consistently operating at the extreme ends of this range will inevitably shorten a seal's life compared to operating in a more moderate thermal environment.

3. System Pressure

PTFE seals can effectively handle pressures exceeding 3.5 MPa (35 BAR or 500 psi). Pressure directly increases the force exerted by the seal lip onto the shaft. This higher contact force leads to increased friction, heat generation, and a faster rate of wear.

4. Chemical and Media Exposure

One of PTFE's greatest strengths is its chemical inertness, making it resistant to nearly all industrial chemicals and lubricants. While chemical attack is rarely a cause of failure, the physical properties of the media are critical. Sealing in an abrasive slurry, for example, will cause mechanical wear far faster than sealing in clean lubricating oil.

Why Not All PTFE Seals Are Created Equal

Beyond the operational environment, the specific construction of the seal itself is a critical variable you can control. The choice of PTFE grade and seal design fundamentally alters its performance characteristics and lifespan.

The Role of Fillers

Different fillers are blended with virgin PTFE to enhance specific properties, directly impacting durability in different scenarios.

- Virgin PTFE: Offers the lowest coefficient of friction but has lower wear resistance. It's best for slow-speed applications where chemical purity is paramount.

- Glass-Filled PTFE: Significantly increases strength and wear resistance, making it suitable for high-pressure and abrasive conditions.

- Carbon-Filled PTFE: Improves wear resistance and thermal conductivity (helping to dissipate heat) without a major increase in friction.

- MoS₂ (Molybdenum Disulfide) Filled PTFE: Acts as a solid lubricant, enhancing wear resistance and performance in dry-running or high-duty applications.

The Impact of Seal Design

The physical shape of the seal lip also plays a major role in its function and longevity.

- Plain Lip: A simple, effective design for general-purpose sealing.

- Hydrodynamic Lip: Features features on the lip that actively pump fluid away from the seal edge, reducing friction, lowering temperature, and extending life in lubricated systems.

- Multi-Lip: Incorporates two or more lips, often used to provide redundant sealing or to exclude external contaminants, thereby protecting the primary sealing lip from abrasive wear.

Understanding the Inherent Trade-offs

Selecting a seal is an exercise in balancing competing properties. Recognizing these trade-offs is key to making an informed decision and avoiding premature failure.

Wear Resistance vs. Shaft Wear

A highly durable, filled PTFE compound (like glass-filled) will resist wear exceptionally well. However, these harder fillers can be more abrasive to the shaft itself. In some cases, it may be preferable for a softer seal to wear out as a sacrificial component rather than damage an expensive and hard-to-replace shaft.

The "Dry-Running" Capability

PTFE's low friction allows it to function without lubrication, a significant advantage over many elastomer seals. However, running a seal completely dry will always result in a shorter lifespan than running it in a lubricated environment. Lubrication remains the single best way to reduce friction, dissipate heat, and maximize the life of any rotary seal.

How to Maximize Seal Lifespan for Your Application

Instead of seeking a single number, focus on aligning the seal's characteristics with your primary operational challenge.

- If your primary focus is high rotational speed: Prioritize a low-friction, heat-dissipating compound like carbon-filled PTFE, ideally with a hydrodynamic lip design to manage the thermal load.

- If your primary focus is high pressure or abrasive media: Select a robust, highly wear-resistant compound such as glass-filled or carbon-filled PTFE to withstand the high mechanical loads.

- If your primary focus is extreme chemical resistance: Choose a grade based on its inertness, possibly virgin PTFE, ensuring that speed and pressure are within its lower mechanical limits.

Ultimately, a seal's lifespan is determined by a deliberate engineering choice that accounts for the complete operational environment.

Summary Table:

| Factor | Typical Range / Key Point | Impact on Lifespan |

|---|---|---|

| Operational Speed | Up to 35 m/s | Higher speed = more friction/heat = faster wear |

| System Temperature | -200°C to +260°C | Extreme temperatures shorten life compared to moderate ranges |

| System Pressure | > 3.5 MPa (500 psi) | Higher pressure = increased lip force = more friction/wear |

| Media Exposure | Chemically inert, but... | Abrasive media causes rapid mechanical wear |

| PTFE Compound | Virgin, Glass, Carbon, MoS₂ filled | Fillers enhance specific properties like wear resistance or lubrication |

| Seal Design | Plain, Hydrodynamic, Multi-Lip | Design manages friction, heat, and contaminant exclusion |

Stop guessing and start engineering the optimal lifespan for your PTFE seals.

At KINTEK, we specialize in manufacturing high-performance, precision PTFE components—including custom rotary shaft seals—for the semiconductor, medical, laboratory, and industrial sectors. The longevity of your seals depends on perfectly matching the PTFE compound and design to your unique application's speed, temperature, pressure, and media.

We help you maximize seal durability by providing:

- Expert Material Selection: Guidance on the ideal PTFE compound (virgin, glass-filled, carbon-filled, etc.) for your primary challenge, whether it's high speed, abrasive media, or chemical resistance.

- Custom Design & Fabrication: From prototypes to high-volume orders, we tailor seal designs (like hydrodynamic lips for heat management) to your exact specifications.

- Precision Production: Ensuring consistent quality and reliable performance in the most demanding environments.

Let's engineer a solution that extends your seal's service life and boosts your operational reliability. Contact KINTEK today to discuss your application requirements and receive a custom consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications