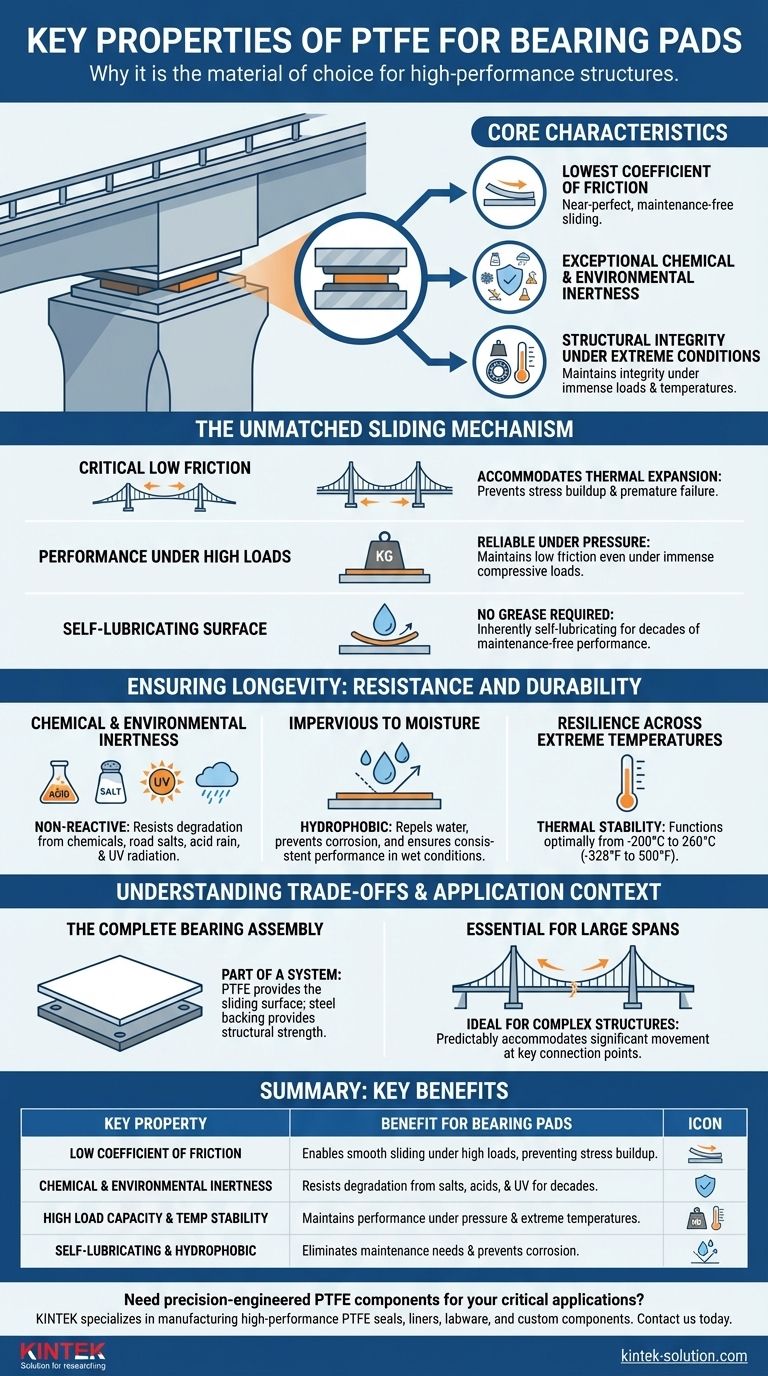

At its core, PTFE is the material of choice for high-performance bearing pads because of three primary characteristics. It possesses the lowest coefficient of friction of any known solid material, exhibits exceptional chemical and environmental inertness, and maintains its structural integrity under immense loads and across extreme temperature ranges. This unique combination allows it to create a near-perfect, maintenance-free sliding surface.

The fundamental challenge for large structures like bridges is accommodating movement from thermal expansion, wind, and seismic activity without transferring damaging stress. PTFE solves this by providing a durable, ultra-low-friction interface that allows components to slide smoothly, effectively isolating the structure from these forces.

The Unmatched Sliding Mechanism: Coefficient of Friction

The most celebrated property of PTFE (Polytetrafluoroethylene) is its incredibly low friction, which is fundamental to its role in bearing pads.

Why Low Friction is Critical

A low coefficient of friction allows structural components to move against each other with minimal resistance. This is essential for accommodating the natural expansion and contraction of materials due to temperature changes.

Without this smooth sliding capability, immense thermal stresses would build up within the structure, potentially leading to cracks and premature failure.

Performance Under High Loads

Critically, PTFE maintains its low-friction properties even when subjected to the high compressive loads found in large bridges and buildings.

This ensures that the bearing performs reliably under the full weight of the structure, allowing surfaces to slide without seizing or binding.

A Self-Lubricating Surface

PTFE is inherently self-lubricating, meaning it does not require grease or any other external lubricants to function.

This eliminates a significant maintenance requirement and ensures consistent performance over the entire lifespan of the bearing, which is often decades long.

Ensuring Longevity: Resistance and Durability

A bearing pad is expected to last for decades in exposed, often harsh environments. PTFE's inherent resilience makes this possible.

Chemical and Environmental Inertness

PTFE is a non-reactive material that does not react with or degrade from exposure to most chemicals, including road salts, acid rain, and pollutants.

It is also highly resistant to weathering and UV radiation, preventing the material from becoming brittle or breaking down over time.

Impervious to Moisture

As a hydrophobic material, PTFE repels water and has an extremely low moisture absorption rate.

This property is vital for preventing corrosion of the bearing's metal components and ensuring consistent performance in wet or humid environments.

Resilience Across Extreme Temperatures

PTFE maintains its key properties at both very high and very low temperatures, withstanding a service range up to 260°C (500°F).

This thermal stability ensures the bearing pad functions as designed, whether in freezing winter conditions or the peak heat of summer.

Understanding the Trade-offs and Application Context

While PTFE's properties are exceptional, its effectiveness is realized when it is correctly integrated into a complete bearing assembly. It is not a standalone structural component.

The Role of the Complete Bearing

PTFE is typically used as a thin sheet bonded to a more robust steel backing plate. It provides the sliding surface, while the steel assembly provides the overall structural strength.

The PTFE layer is often dimpled to retain a specialized silicone lubricant, which further reduces the initial coefficient of friction, though the material functions perfectly without it.

Why It's Essential for Large Spans

The larger the bridge or structure, the greater the potential for movement. PTFE's properties make it ideal for large-span bridges, continuous beams, and other structures where significant displacement must be safely accommodated.

It enables complex designs by allowing for predictable movement at key connection points, such as between a bridge deck and its piers.

Limitations to Consider

The primary limitation is not in the material itself, but in its application. The design of the entire bearing assembly—including the steel plates and elastomeric components—is just as critical as the PTFE surface.

Improper design or installation can lead to uneven loading or contamination of the sliding surface, which can compromise the bearing's performance.

Making the Right Choice for Your Goal

Selecting the right bearing material depends on balancing structural demands with environmental conditions and lifespan requirements.

- If your primary focus is accommodating thermal expansion and contraction: PTFE's unparalleled low coefficient of friction is the most critical property, as it prevents stress accumulation.

- If your primary focus is long-term durability in a harsh environment: PTFE's chemical inertness and resistance to weathering ensure a maintenance-free service life of many decades.

- If your primary focus is supporting complex loads and movements: PTFE's ability to handle high vertical loads while allowing for shear and rotation makes it suitable for the most demanding structural designs.

Ultimately, PTFE enables engineers to design resilient, long-lasting structures by providing a simple and reliable solution to the complex problem of managing movement.

Summary Table:

| Key Property | Benefit for Bearing Pads |

|---|---|

| Low Coefficient of Friction | Enables smooth sliding under high loads, preventing stress buildup from thermal expansion. |

| Chemical & Environmental Inertness | Resists degradation from salts, acids, and UV radiation for decades-long service life. |

| High Load Capacity & Temperature Stability | Maintains performance under immense pressure and across extreme temperature ranges (-200°C to 260°C). |

| Self-Lubricating & Hydrophobic | Eliminates maintenance needs and prevents corrosion by repelling water and requiring no grease. |

Need precision-engineered PTFE components for your critical applications?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get components that meet exact specifications for durability, chemical resistance, and performance.

Contact us today to discuss how our PTFE solutions can enhance your project's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability