At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of extreme resistances. Its defining characteristics are an exceptionally low coefficient of friction, near-total chemical inertness, excellent performance across a wide temperature range, and outstanding electrical insulation.

PTFE is not a general-purpose plastic; it is a specialty material engineered for extreme environments. Its value comes from its ability to perform reliably where other materials would fail due to chemical attack, high temperatures, or the need for a non-stick, low-friction surface.

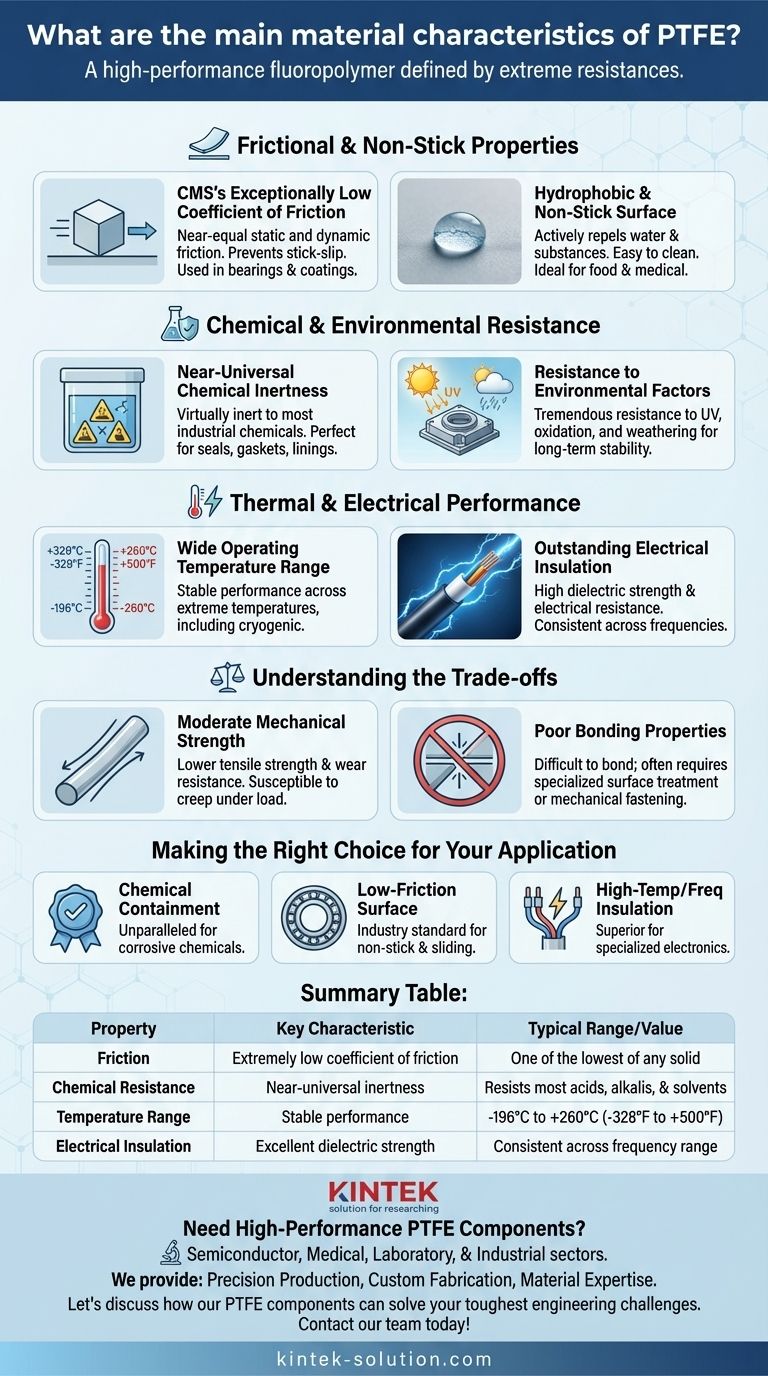

Frictional and Non-Stick Properties

The surface characteristics of PTFE are among its most well-known attributes, making it invaluable in a range of mechanical and industrial applications.

Exceptionally Low Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. Its surface is so slick that its static and dynamic friction coefficients are nearly equal, preventing stick-slip motion.

This property is responsible for its use in non-stick coatings, like Teflon, and in low-friction bearings and bushings.

Hydrophobic and Non-Stick Surface

The material is hydrophobic, meaning it actively repels water and water-based substances. This contributes to its excellent non-stick and anti-fouling capabilities.

Because very few substances can permanently adhere to its surface, it is easy to clean and is widely used in food processing and medical applications.

Chemical and Environmental Resistance

PTFE's molecular structure makes it one of the most chemically resistant polymers available. It offers superior reliability in corrosive and harsh environments.

Near-Universal Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, including aggressive acids, alkalis, and organic solvents. This makes it an ideal material for seals, gaskets, and linings in chemical processing equipment.

Resistance to Environmental Factors

The material demonstrates tremendous resistance to weathering, UV radiation, and oxidation. This ensures long-term stability and performance in outdoor or exposed applications where other plastics might degrade.

Thermal and Electrical Performance

PTFE maintains its integrity and properties across an unusually broad spectrum of temperatures and electrical conditions.

Wide Operating Temperature Range

PTFE is stable and functional across a vast temperature range, typically cited as -196°C to +260°C (-328°F to +500°F). It retains its properties, including flexibility, even at cryogenic temperatures.

Outstanding Electrical Insulation

It is an exceptional electrical insulator with high dielectric strength and high electrical resistance. Critically, these insulating properties remain consistent across a wide range of frequencies, making it a preferred material for high-frequency electronics and cable insulation.

Understanding the Trade-offs

While its specialized properties are remarkable, PTFE is not without its limitations. Understanding these trade-offs is crucial for proper material selection.

Moderate Mechanical Strength

Compared to engineering plastics like nylon or PEEK, PTFE has relatively low tensile strength and wear resistance. It is a soft material that can be susceptible to creep and deformation under sustained load.

Poor Bonding Properties

The same non-stick properties that make PTFE so useful also make it very difficult to bond to other materials. Attaching PTFE components often requires specialized surface treatments like chemical etching or mechanical fastening.

Making the Right Choice for Your Application

Selecting PTFE is a decision driven by the need to solve a specific, demanding engineering challenge.

- If your primary focus is chemical containment: PTFE is an unparalleled choice for seals, linings, and components that will be exposed to highly corrosive chemicals.

- If your primary focus is a low-friction surface: PTFE is the industry standard for non-stick coatings, slide bearings, and any application where minimizing friction is critical.

- If your primary focus is high-temperature or high-frequency insulation: PTFE's stable thermal and electrical properties make it a superior material for specialized wiring, cables, and electronic components.

Ultimately, PTFE should be chosen for its unique ability to thrive in conditions that would cause most other materials to fail.

Summary Table:

| Property | Key Characteristic | Typical Range/Value |

|---|---|---|

| Friction | Extremely low coefficient of friction | One of the lowest of any solid |

| Chemical Resistance | Near-universal inertness | Resists most acids, alkalis, and solvents |

| Temperature Range | Stable performance | -196°C to +260°C (-328°F to +500°F) |

| Electrical Insulation | Excellent dielectric strength | Consistent across a wide frequency range |

Need High-Performance PTFE Components?

PTFE's unique properties make it ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Whether you require custom seals, liners, labware, or other critical components, KINTEK has the expertise to deliver.

We provide:

- Precision Production: Ensuring the highest quality and performance for your specific needs.

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Material Expertise: Helping you select the right PTFE solution for extreme environments.

Let's discuss how our PTFE components can solve your toughest engineering challenges. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the standard sizes available for PTFE sheets and rods? Optimize Your Design & Sourcing

- What was the key finding about Teflon's friction mechanism? Unlocking the Secret of Its Self-Lubricating Slipperiness

- Is PTFE the same as Teflon? Understanding the Brand vs. Material Distinction

- What are some additional physical properties of PTFE? Beyond Non-Stick: Discover PTFE's Elite Thermal & Chemical Resistance

- What makes PTFE versatile for various industrial uses? Discover the Key Properties Driving Its Success

- What are the additional beneficial properties of PTFE besides corrosion resistance? Leverage Its Full Potential for High-Performance Applications

- What are the unique surface properties of PTFE? Leverage Unmatched Slipperiness and Non-Stick Performance

- Why is PTFE used in medical and pharmaceutical applications? The Ultimate Guide to Safety and Performance