At its core, Polytetrafluoroethylene (PTFE) possesses two defining surface properties that are unmatched in the world of solid materials. It has the lowest coefficient of friction of any known solid, making it exceptionally slippery. Simultaneously, it has one of the lowest surface tensions, which is the force that makes it profoundly non-stick and non-adhesive to virtually any other substance.

The unique surface characteristics of PTFE are not independent features; they are direct consequences of its stable and simple molecular structure. This structure creates a material that is simultaneously one of the most useful for release and low-friction applications and one of the most challenging to bond or modify.

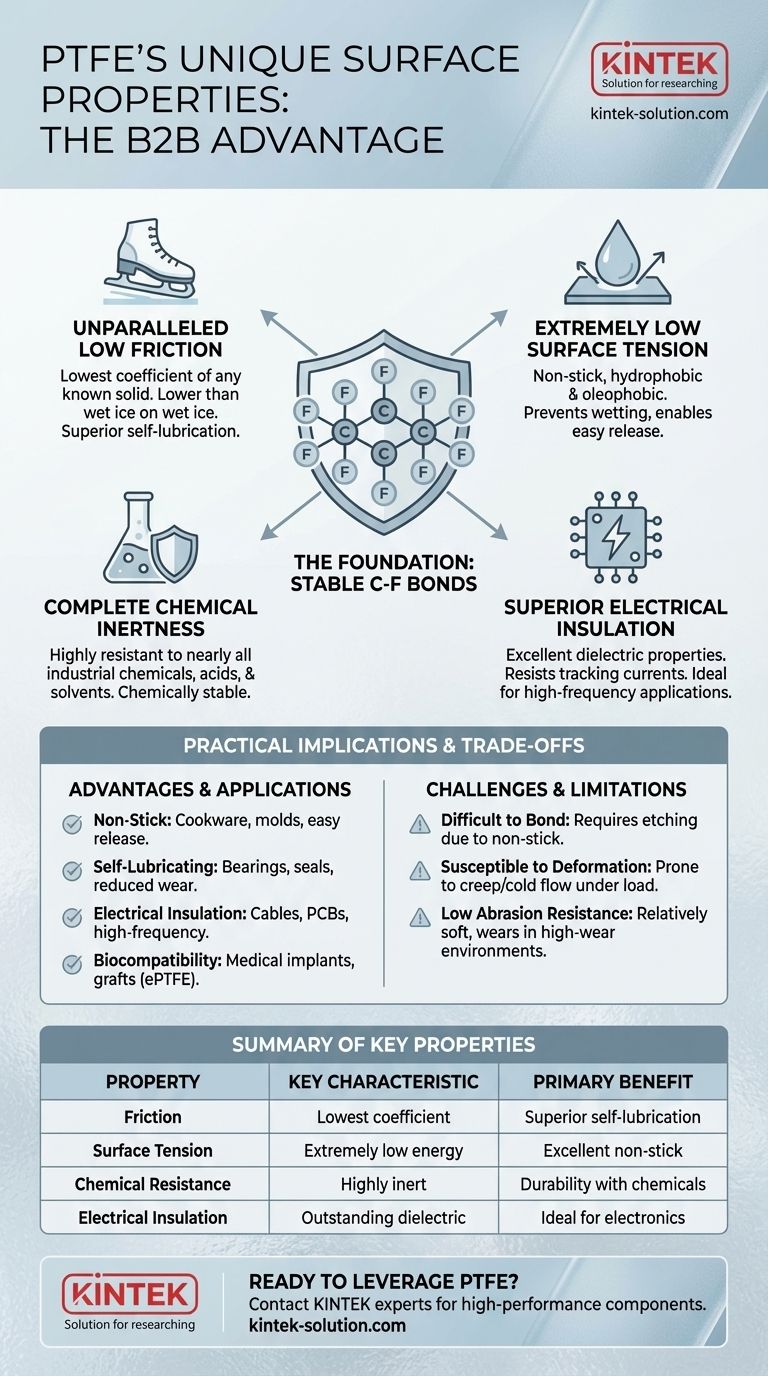

The Foundation of PTFE's Unique Surface

PTFE's properties are a direct result of the strong bonds between carbon and fluorine atoms that shield the carbon backbone of the polymer. This creates a surface that is chemically stable and has very weak intermolecular forces available to interact with other materials.

Unparalleled Low Friction

PTFE is famously known as the most slippery solid material in existence, with a coefficient of friction lower than that of wet ice on wet ice.

This extreme slipperiness means that surfaces coated with PTFE can move against each other with minimal energy loss or wear, making it a superior self-lubricating material.

Extremely Low Surface Tension

Surface tension is the property that causes liquids to form beads. PTFE's surface has extremely low energy, preventing most substances from "wetting" or spreading across it.

This results in a surface that is both hydrophobic (water-repellent) and oleophobic (oil- and grease-repellent), which is the primary reason for its famous non-stick quality.

Complete Chemical Inertness

The powerful carbon-fluorine bonds make the surface of PTFE almost completely inert and non-reactive.

It is highly resistant to nearly all industrial chemicals, acids, alkalis, and organic solvents, ensuring its surface properties do not degrade upon exposure.

Practical Implications of These Properties

The combination of low friction, low surface tension, and chemical stability makes PTFE invaluable across numerous industries.

The Non-Stick Advantage

The non-stick quality is critical in applications like cookware, but also in industrial molds for plastics and composites, where easy release of the finished part is essential.

The Self-Lubricating Effect

In mechanical systems, PTFE coatings, bearings, and seals dramatically reduce friction between moving parts. This minimizes wear, reduces maintenance, and improves energy efficiency.

Superior Electrical Insulation

PTFE's surface is an excellent electrical insulator that resists tracking currents. Its outstanding dielectric properties make it a preferred material for high-frequency applications like coaxial cables and printed circuit boards.

Biocompatibility and Purity

Because its surface is so inert and stable, it is non-toxic and biocompatible. This allows modified forms like ePTFE to be used in medical implants, grafts, and sutures.

Understanding the Trade-offs and Limitations

The very properties that make PTFE so useful also introduce significant challenges that must be managed in any design.

The Bonding and Printing Challenge

A direct consequence of its low surface tension and non-stick nature is that it is extremely difficult to bond PTFE to other materials. Standard adhesives will not work without first chemically or physically etching the surface to create anchor points.

Susceptibility to Deformation

PTFE is a relatively soft material. Under sustained load, it is prone to "creep" or cold flow, where the material slowly deforms over time. This can alter the integrity of a seal or the tolerance of a bearing.

Low Abrasion Resistance

While its friction is low, PTFE itself is not exceptionally hard. Its surface can be worn away by abrasive materials, limiting its use in high-wear environments unless it is reinforced with fillers like glass or carbon.

Making the Right Choice for Your Application

Leveraging PTFE requires matching its unique surface properties to your primary engineering goal.

- If your primary focus is reducing mechanical friction: PTFE's exceptionally low friction coefficient makes it the ideal choice for self-lubricating bearings, seals, and low-wear coatings.

- If your primary focus is creating a non-stick, easy-clean surface: Its extremely low surface tension provides superior release properties for cookware, industrial molds, and chemical processing equipment.

- If your primary focus is high-frequency electrical insulation: PTFE's excellent dielectric properties and resistance to current tracking make it a top-tier material for high-performance cables and circuit boards.

- If your primary focus is absolute chemical resistance: Its inert surface ensures it will not react with or degrade when exposed to nearly all industrial solvents, acids, and bases.

Understanding these interconnected surface properties allows you to leverage PTFE's unique advantages while proactively managing its inherent limitations.

Summary Table:

| Property | Key Characteristic | Primary Benefit |

|---|---|---|

| Friction | Lowest coefficient of any solid | Superior self-lubrication for bearings and seals |

| Surface Tension | Extremely low energy | Excellent non-stick and easy-release performance |

| Chemical Resistance | Highly inert and non-reactive | Durability with acids, solvents, and alkalis |

| Electrical Insulation | Outstanding dielectric properties | Ideal for high-frequency cables and circuit boards |

Ready to leverage PTFE's unique properties in your application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, labware, and more. Whether you need a prototype for testing or a high-volume production run for the semiconductor, medical, or industrial sectors, our expertise ensures you get a component that maximizes PTFE's advantages while accounting for its limitations.

Contact our experts today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers