Yes, Teflon is the brand name for PTFE. Polytetrafluoroethylene (PTFE) is the generic chemical name for the polymer, while Teflon™ is the trademarked brand name under which it is sold by the company Chemours. All products branded as Teflon are made from PTFE, but not all PTFE products are branded as Teflon.

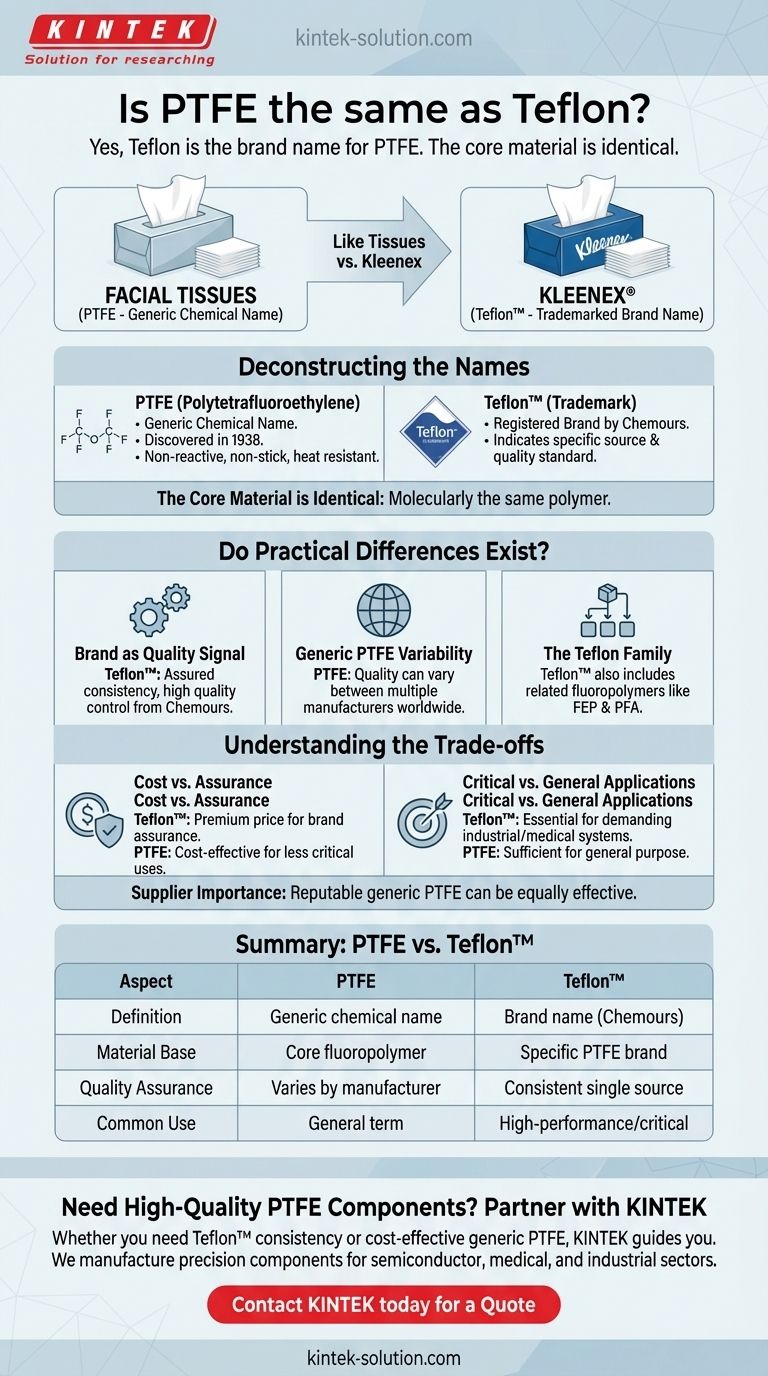

Think of the relationship between PTFE and Teflon exactly like the one between facial tissues and Kleenex. Kleenex is a specific brand of tissue, but many other companies also manufacture tissues. The core material is the same, but the brand signifies a specific source and standard of quality.

Deconstructing the Names: Chemical vs. Brand

Understanding the distinction between the technical name and the market name is the key to clarity. These terms describe the same core substance but from different perspectives.

What is PTFE?

PTFE is the abbreviation for polytetrafluoroethylene. This is the specific chemical name for a synthetic fluoropolymer discovered in 1938.

Its properties—being extremely non-reactive, non-stick, and resistant to high temperatures—make it incredibly useful in countless industrial and consumer applications.

What is Teflon™?

Teflon is the registered trademark for PTFE-based products, currently owned by Chemours (a spin-off from DuPont).

When a company invents a new material, it gives it a chemical name (PTFE) and often a marketable trade name (Teflon) to build brand recognition and a reputation for quality.

The Core Material is Identical

At a molecular level, the pure PTFE polymer in a generic product is identical to the pure PTFE polymer in a Teflon-branded product. The chemical formula and the inherent properties of the material do not change.

Do Practical Differences Exist?

While the base chemical is the same, the distinction can matter in terms of quality control, consistency, and product variations. The real question is not about the chemical itself, but about the manufacturing and formulation of the final product.

Brand as a Quality Signal

Choosing a Teflon-branded product means you are buying from a specific manufacturer (Chemours) with a long-standing reputation. This often implies a high degree of quality control and consistency in the manufacturing process.

Generic PTFE and Manufacturer Variability

Because PTFE is a generic term, materials sold under this name can come from numerous manufacturers worldwide. While many produce high-quality PTFE, the consistency and purity can vary between suppliers.

The Teflon Family of Products

It's also important to note that the Teflon brand is used to market a family of related fluoropolymers, not just PTFE. This includes materials like PFA (perfluoroalkoxy alkane) and FEP (fluorinated ethylene propylene), which share properties with PTFE but offer different benefits, such as easier melt-processing or greater clarity.

Understanding the Trade-offs

Choosing between generic PTFE and branded Teflon involves balancing cost, performance requirements, and acceptable risk.

Cost vs. Brand Assurance

Teflon-branded products often come at a premium price. This cost reflects the brand's marketing, research, and reputation for quality assurance. For less critical applications, a reputable generic PTFE can be a more cost-effective solution.

Critical vs. General Applications

For demanding industrial, medical, or aerospace applications, the guaranteed consistency of a branded product like Teflon can be essential. For a non-stick frying pan or simple gasket, the functional difference is often negligible.

The Importance of the Supplier

Ultimately, the quality of a PTFE product—branded or not—depends heavily on the manufacturer. A reputable supplier of generic PTFE can provide a product that is just as effective as its branded counterpart for a specific application.

Making the Right Choice for Your Goal

Your decision should be driven by your application's specific needs, not just by the name on the label.

- If your primary focus is cost-effectiveness for a general-purpose application: A well-sourced generic PTFE product is typically more than sufficient.

- If your primary focus is guaranteed consistency for a high-performance or critical system: Choosing a Teflon-branded product provides a reliable benchmark for quality and traceability.

- If you need specific properties beyond standard PTFE (e.g., optical clarity or easier fabrication): Investigate the entire Teflon family of fluoropolymers, such as FEP or PFA, to find the ideal material.

Understanding that Teflon is a type of PTFE empowers you to look past the marketing and choose a material based on its technical merits and your project's unique requirements.

Summary Table:

| Aspect | PTFE | Teflon™ |

|---|---|---|

| Definition | Generic chemical name (Polytetrafluoroethylene) | Brand name owned by Chemours |

| Material Base | The core fluoropolymer | A specific brand of PTFE |

| Quality Assurance | Can vary by manufacturer | Consistent quality from a single source |

| Common Use | General term for the material | Often used for high-performance/critical applications |

Need High-Quality PTFE Components? Partner with KINTEK

Whether your project requires the proven consistency of Teflon-branded materials or a cost-effective, high-performance generic PTFE solution, KINTEK has the expertise to guide you. We manufacture precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the right material for your specific application requirements and budget.

Contact KINTEK today to discuss your PTFE needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support