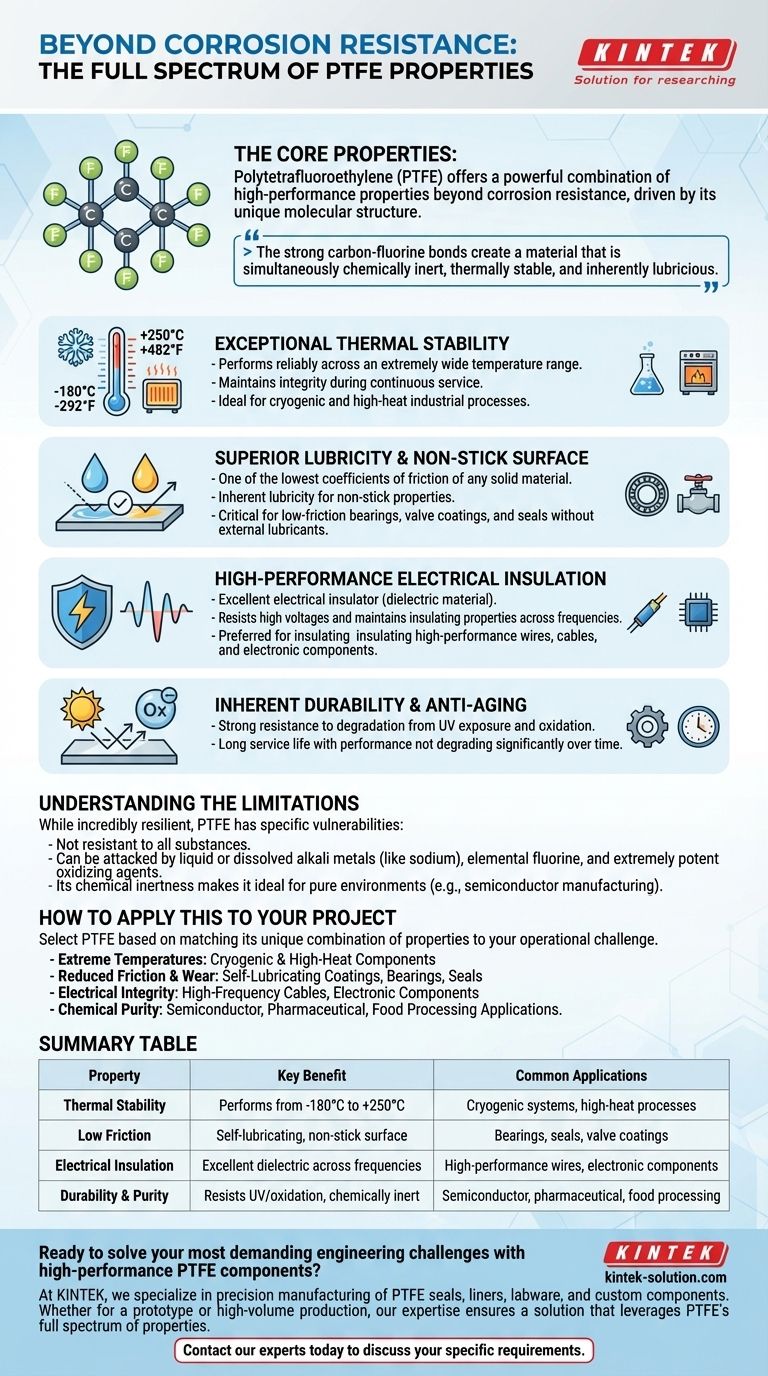

Beyond its renowned corrosion resistance, Polytetrafluoroethylene (PTFE) offers a powerful combination of other high-performance properties. Its primary benefits also include exceptionally low friction for non-stick surfaces, excellent thermal stability across a vast temperature range, and effective electrical insulation.

The true value of PTFE lies in its unique molecular structure. The strong carbon-fluorine bonds create a material that is simultaneously chemically inert, thermally stable, and inherently lubricious, making it a problem-solver for many of engineering's most demanding environments.

The Core Properties Driving PTFE's Versatility

While often celebrated for its chemical resistance, PTFE's utility in applications from aerospace to electronics is driven by a distinct set of characteristics.

Exceptional Thermal Stability

PTFE, commonly known by the trade name Teflon, performs reliably across an extremely wide temperature range.

It maintains its integrity and properties during continuous service from -180°C up to +250°C (-292°F to +482°F). This makes it suitable for both cryogenic and high-heat industrial processes where other polymers would fail.

Superior Lubricity and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This inherent lubricity is responsible for its famous non-stick properties.

This characteristic is critical not only for consumer cookware but also for industrial applications like low-friction bearings, distribution valve coatings, and seals that must operate smoothly without external lubricants.

High-Performance Electrical Insulation

The fluorocarbon-based polymer structure makes PTFE an excellent electrical insulator, or dielectric material.

It resists high voltages and maintains its insulating properties across a wide range of frequencies. This makes it a preferred choice for insulating high-performance wires, cables, and sensitive electronic components where signal integrity is paramount.

Inherent Durability and Anti-Aging

PTFE exhibits strong resistance to degradation from environmental factors.

It resists oxidation and damage from UV exposure, contributing to a very long service life. This "anti-aging" property ensures its performance does not degrade significantly over time, even with continuous exposure.

Understanding the Limitations

No material is perfect, and being an effective technical professional requires understanding a material's boundaries. While incredibly resilient, PTFE does have specific vulnerabilities.

Known Chemical Vulnerabilities

PTFE is nearly impervious to most acids, bases, and solvents, even at high temperatures.

However, it is not resistant to all substances. It can be attacked by liquid or dissolved alkali metals (like sodium), elemental fluorine, and other extremely potent oxidizing agents.

Suitability for Pure Environments

Because PTFE is chemically inert, it does not degrade or leach contaminants into the substances it contacts.

This makes it an ideal material for applications requiring high purity, such as in clean rooms, semiconductor manufacturing, and systems handling deionized water.

How to Apply This to Your Project

Selecting PTFE is about matching its unique combination of properties to your specific operational challenge.

- If your primary focus is performance in extreme temperatures: PTFE's wide operating range makes it ideal for components in both cryogenic and high-heat applications.

- If your primary focus is reducing friction and wear: Its non-stick surface and low coefficient of friction are perfect for creating self-lubricating coatings, bearings, and dynamic seals.

- If your primary focus is electrical integrity: Its excellent dielectric properties make it a superior choice for insulating critical electronic components and high-frequency cables.

- If your primary focus is chemical purity: Its inertness is essential for applications in semiconductor, pharmaceutical, or food processing where preventing contamination is critical.

Understanding the full spectrum of PTFE's properties allows you to leverage it not just as a protective barrier, but as a multifunctional engineering solution.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Thermal Stability | Performs from -180°C to +250°C | Cryogenic systems, high-heat processes |

| Low Friction | Self-lubricating, non-stick surface | Bearings, seals, valve coatings |

| Electrical Insulation | Excellent dielectric across frequencies | High-performance wires, electronic components |

| Durability & Purity | Resists UV/oxidation, chemically inert | Semiconductor, pharmaceutical, food processing |

Ready to solve your most demanding engineering challenges with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components. Whether you need a prototype for a new application or high-volume production for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures a solution that leverages PTFE's full spectrum of properties for superior performance, purity, and longevity.

Contact our experts today to discuss your specific requirements and discover how our custom PTFE fabrication can benefit your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability