At its core, the versatility of Polytetrafluoroethylene (PTFE) stems from an exceptional combination of four key properties: extreme chemical inertness, high-temperature stability, a very low coefficient of friction, and superior electrical insulation. This unique suite of characteristics makes it a premier problem-solving material in industries where other plastics would quickly fail.

PTFE's value isn't derived from a single standout feature, but from the powerful synergy of its chemical, thermal, frictional, and electrical properties. This allows it to be molded, machined, and enhanced to perform reliably in the most demanding industrial environments.

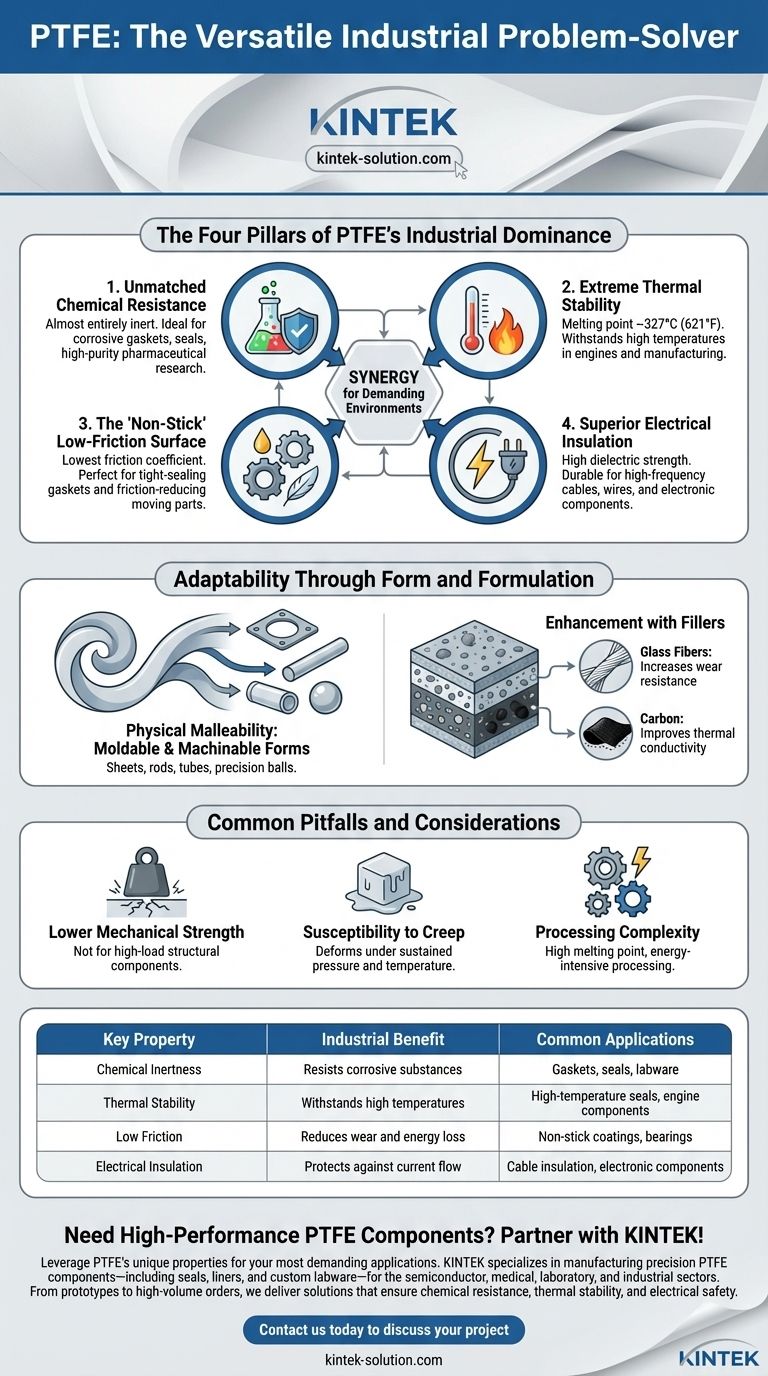

The Four Pillars of PTFE's Industrial Dominance

PTFE's adaptability can be understood by examining its four foundational characteristics. Each one solves a distinct set of engineering challenges.

1. Unmatched Chemical Resistance

PTFE is almost entirely inert, meaning it does not react with the vast majority of industrial chemicals, acids, and bases.

This property makes it invaluable for applications involving corrosive substances, such as gaskets and seals in chemical processing plants. It's also critical in high-purity settings like pharmaceutical research and chromatography, ensuring no material leaches into or reacts with sensitive samples.

2. Extreme Thermal Stability

With a melting point around 327°C (621°F), PTFE maintains its structural integrity and performance across a very wide operating temperature range.

It can withstand repeated exposure to high temperatures without degrading or breaking down. This makes it a go-to material for high-temperature seals and components in engines, manufacturing equipment, and other heat-intensive systems.

3. The 'Non-Stick' Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it its famously slick, non-stick surface.

This property is essential for gaskets that need to seal tightly without adhering to flange surfaces, and for any moving parts where reducing friction is a primary concern.

4. Superior Electrical Insulation

PTFE exhibits a very high dielectric strength, making it an exceptional electrical insulator that resists the flow of electric current.

It is more durable and resistant to moisture penetration than materials like PVC or nylon. This makes it the ideal choice for insulating high-frequency data cables, wrapping wires, and creating standoff insulators for high-voltage electronic components.

Adaptability Through Form and Formulation

Beyond its inherent chemical and physical properties, PTFE's versatility is amplified by its ability to be physically and structurally modified for specific tasks.

Physical Malleability

PTFE is not a rigid, unchangeable substance. It can be readily molded, machined, or extruded into a wide variety of forms.

This includes sheets for gaskets, rods for custom-machined parts, tubes for fluid transfer, and even precision balls for check valves. This physical adaptability allows it to be engineered into the precise shape an application requires.

Enhancement with Fillers

The base properties of PTFE can be augmented by adding fillers to the polymer during manufacturing. This creates composite materials tailored to specific performance needs.

For example, adding glass fibers significantly increases wear resistance, while adding carbon improves thermal conductivity, helping to dissipate heat more effectively in certain applications.

Common Pitfalls and Considerations

While remarkably capable, PTFE is not the solution for every problem. Understanding its trade-offs is key to using it effectively.

Lower Mechanical Strength

Compared to many engineering plastics, PTFE is relatively soft and has lower tensile strength. It is not typically used for high-load structural components.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform over time—a phenomenon known as "creep." This must be accounted for in the design of joints and seals.

Processing Complexity

Due to its high melting point and viscosity, processing PTFE is more complex and energy-intensive than working with more common thermoplastics.

Making the Right Choice for Your Application

To leverage PTFE's strengths, align its properties with your primary engineering goal.

- If your primary focus is sealing corrosive or high-temperature fluids: PTFE's chemical inertness and thermal stability make it the definitive choice for gaskets and seals.

- If your primary focus is electrical safety and performance: Its high dielectric strength and moisture resistance offer unparalleled reliability for insulation in critical electronics.

- If your primary focus is reducing friction in moving parts: Its ultra-low coefficient of friction provides a non-stick surface that minimizes wear and energy loss.

- If your primary focus is high-purity lab work: Its inertness and purity are essential for applications in chromatography and pharmaceutical research where contamination is not an option.

Ultimately, PTFE's role as an industrial staple is secured by its ability to solve problems in environments where lesser materials simply cannot survive.

Summary Table:

| Key Property | Industrial Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists corrosive substances | Gaskets, seals, labware |

| Thermal Stability | Withstands high temperatures | High-temperature seals, engine components |

| Low Friction | Reduces wear and energy loss | Non-stick coatings, bearings |

| Electrical Insulation | Protects against current flow | Cable insulation, electronic components |

Need High-Performance PTFE Components? Partner with KINTEK!

Leverage PTFE's unique properties for your most demanding applications. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver solutions that ensure chemical resistance, thermal stability, and electrical safety.

Contact us today to discuss your project and discover how our custom PTFE fabrication can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the different types of Teflon available? A Guide to PTFE, FEP, PFA, and More

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE