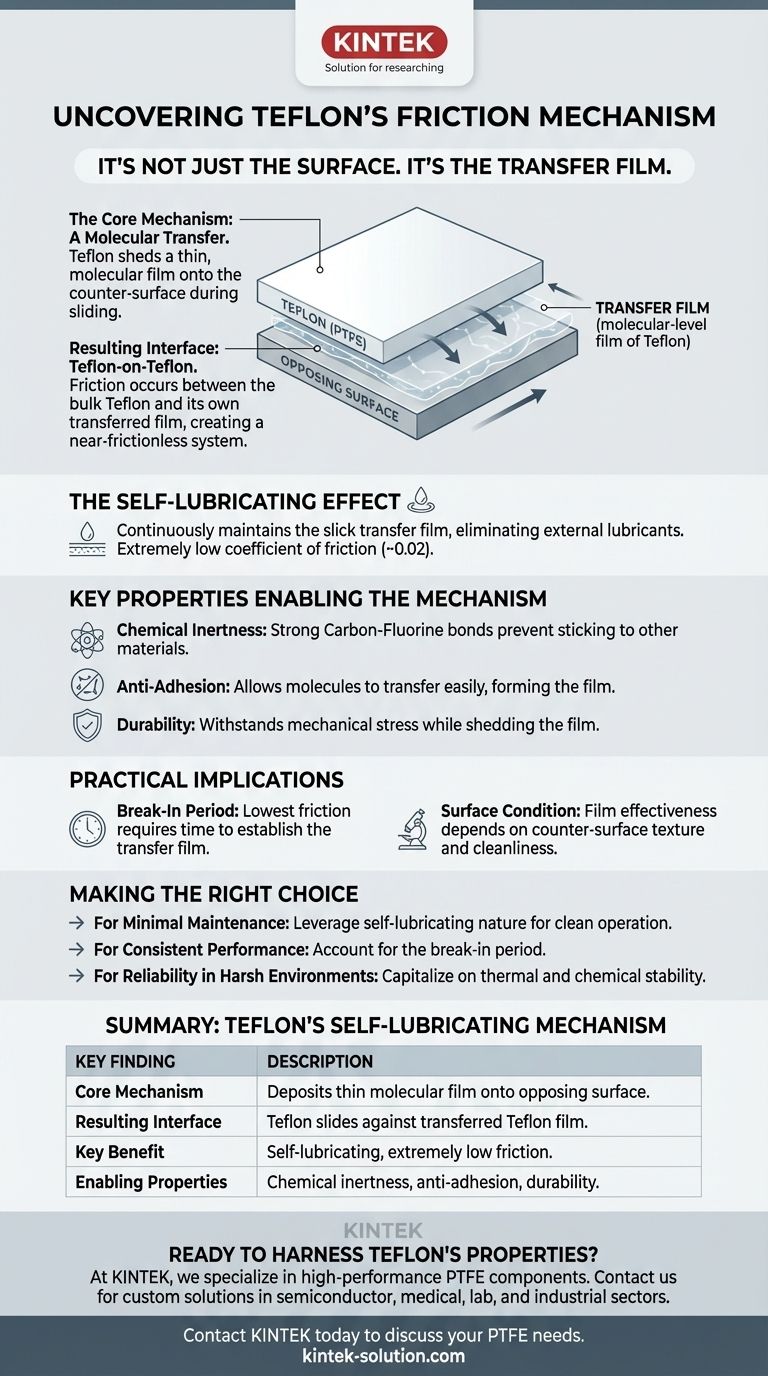

The key finding is that Teflon's low friction is not simply an inherent property of its surface. Instead, when Teflon slides against another material, it deposits an exceptionally thin, molecular-level film of itself onto that surface, causing the Teflon to then slide against its own film.

The secret to Teflon's legendary slipperiness is not just what it is, but what it does. It achieves its low friction by creating a "Teflon-on-Teflon" interface, effectively lubricating the surface with a microscopic layer of itself.

The Self-Lubricating Transfer Film

Understanding this mechanism is crucial because it explains why Teflon (PTFE) behaves so differently from other materials. It isn't just slick; it actively modifies the opposing surface to create a near-frictionless system.

The Core Mechanism: A Molecular Transfer

When pressure and motion are applied, Teflon sheds a thin film, often just a few nanometers thick, onto the counter-surface.

This transfer film bonds to the opposing material. From that point on, the bulk Teflon part is no longer sliding against the original surface but against this newly deposited Teflon layer.

Why This is So Effective

The bond between two Teflon surfaces is incredibly weak, which is why it has such a low coefficient of friction (as low as 0.02 dynamically).

This process is effectively self-lubricating. As long as the part is in motion, it continuously maintains this slick transfer film, eliminating the need for external oils or greases.

Key Properties That Enable This Function

Teflon's unique friction mechanism is only possible because of its underlying molecular structure and resulting material properties.

Chemical Inertness and Anti-Adhesion

Teflon is built on strong carbon-fluorine bonds, making it chemically inert and non-reactive.

This means it doesn't want to stick to other materials, which allows its molecules to transfer easily and form the lubricating film rather than binding aggressively to the counter-surface.

Durability and Wear Resistance

Despite its slipperiness, Teflon is a durable material with respectable tensile strength (up to 30 MPa) and hardness.

This resilience allows it to withstand mechanical stress while still shedding the necessary transfer film, ensuring the mechanism functions over a long operational life.

Understanding the Practical Implications

While this mechanism is highly effective, appreciating how it works reveals important considerations for its application.

The "Break-In" Period

The lowest friction state is not instantaneous. A brief "break-in" or "run-in" period is often required for the transfer film to be fully established on the counter-surface.

Surface Condition Matters

The effectiveness of the film transfer can be influenced by the texture and cleanliness of the opposing surface. A surface that can properly accept the thin film will yield the best results.

Making the Right Choice for Your Goal

Harnessing Teflon's properties requires aligning its mechanism with your engineering objective.

- If your primary focus is minimal maintenance: Leverage Teflon's self-lubricating nature for components that are difficult to access or must operate cleanly without wet lubricants.

- If your primary focus is consistent performance: Ensure your design allows for a brief run-in period to establish the crucial Teflon-on-Teflon transfer film.

- If your primary focus is reliability in harsh environments: Capitalize on Teflon's thermal and chemical stability, which ensures its friction mechanism works flawlessly under conditions that would degrade other materials.

Ultimately, understanding that Teflon creates its own ideal sliding surface is the key to unlocking its full potential.

Summary Table:

| Key Finding | Description |

|---|---|

| Core Mechanism | Teflon deposits a thin, molecular film onto the opposing surface during sliding. |

| Resulting Interface | Friction occurs between the bulk Teflon and the transferred Teflon film (Teflon-on-Teflon). |

| Key Benefit | Self-lubricating action with an extremely low coefficient of friction (~0.02). |

| Enabling Properties | Chemical inertness, anti-adhesion, and durability enable the transfer film mechanism. |

Ready to harness Teflon's unique self-lubricating properties for your application?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE (Teflon) components like seals, liners, and custom labware. Our expertise ensures you get the full benefit of this low-friction mechanism for applications in the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders, guaranteeing reliability and performance in even the harshest environments.

Contact KINTEK today to discuss how our PTFE solutions can reduce maintenance and enhance the performance of your systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance