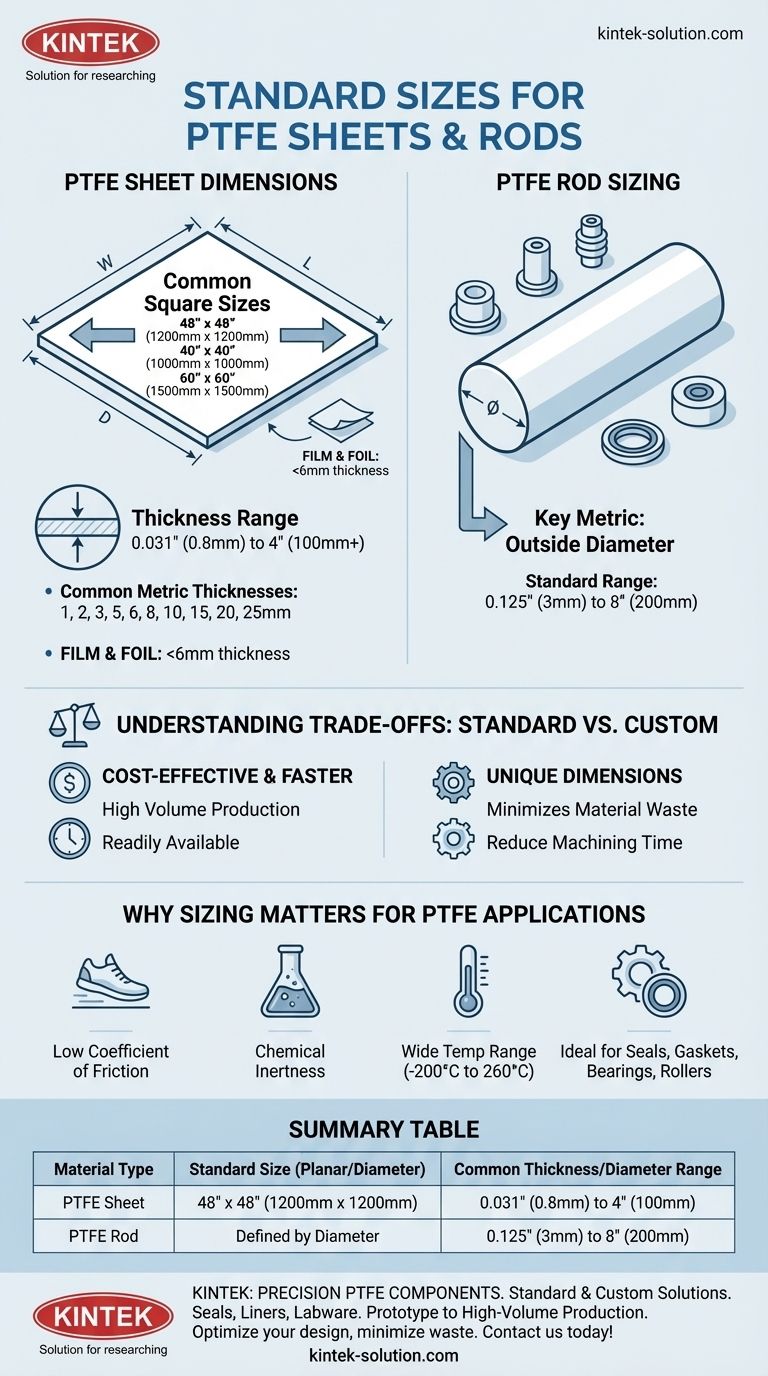

To answer your question directly, standard PTFE sheets are commonly available in square dimensions of 48" x 48" (or 1200mm x 1200mm), with thicknesses ranging from approximately 0.031" (0.8mm) up to 4" (100mm) or more. Standard PTFE rods are defined by their outside diameter, which typically ranges from 0.125" (3mm) to 8" (200mm).

While standard sizes offer cost-effectiveness and ready availability, the true value of PTFE lies in its versatility. Understanding the common stock dimensions is the first step, but recognizing that customization is widely available is key to matching the material precisely to your engineering needs.

A Closer Look at PTFE Sheet Dimensions

When sourcing PTFE sheets, you will encounter both imperial and metric standards. The most critical dimensions are the sheet's planar size (length and width) and its thickness.

Common Imperial and Metric Sizes

Manufacturers typically produce large master sheets that are then cut down. The most common off-the-shelf square sizes you will find are:

- 1000mm x 1000mm (~40" x 40")

- 1200mm x 1200mm (~48" x 48")

- 1500mm x 1500mm (~60" x 60")

The 48" x 48" (or 1200mm x 1200mm) size is an extremely common industry standard.

Standard Thickness Range

PTFE sheet thickness can vary significantly, from very thin films to thick blocks. Standard increments are readily available, including common metric thicknesses like 1, 2, 3, 5, 6, 8, 10, 15, 20, and 25mm.

The overall available range generally spans from 0.031 inches (0.8mm) to 4 inches (100mm), with some suppliers offering even thicker options up to 150mm.

Beyond Sheets: Film and Foil

For applications requiring thicknesses below approximately 6mm, the material is often categorized as PTFE film or foil. This is important to note when your design calls for very thin, flexible barriers or liners.

Understanding PTFE Rod Sizing

For cylindrical parts, PTFE rods are the standard starting stock. The primary measurement here is straightforward.

Diameter as the Key Metric

PTFE rods are specified and sold based on their outside diameter. Standard lengths are often produced, but the diameter is the critical dimension for sourcing.

Typical Diameter Range

You can typically source PTFE rods in diameters ranging from 0.125 inches (3mm) up to 8 inches (200mm). This wide range covers everything from small bushings and electrical insulators to large rollers and seals.

Understanding the Trade-offs

Choosing between standard and custom sizes involves balancing cost, lead time, and material waste. The properties of PTFE itself often dictate the need for precise dimensions.

The Advantage of Standard Stock

Opting for a standard sheet or rod size is almost always more cost-effective and faster. These sizes are produced in high volumes and are readily available from suppliers, minimizing lead times for your project.

When to Consider Customization

Most suppliers offer custom cutting and sizing services. If your part has unique dimensions, ordering custom-cut pieces can significantly reduce your own machining time and minimize material waste, potentially offsetting the higher initial cost.

Why Sizing Matters for PTFE Applications

The exceptional properties of PTFE are what make it so valuable. Its extremely low coefficient of friction, chemical inertness, and wide operating temperature range (-200°C to 260°C) make it ideal for demanding applications like seals, gaskets, bearings, and rollers. Sourcing the correct initial stock size is crucial for manufacturing these components efficiently and to the required tolerance.

Making the Right Choice for Your Goal

Your project's specific goals will determine the best approach to sourcing PTFE material.

- If your primary focus is rapid prototyping or cost-efficiency: Design your parts to be machined from standard, off-the-shelf sheet and rod sizes to ensure the lowest cost and fastest availability.

- If your primary focus is minimizing material waste: Select the standard stock size that is closest to your final part dimensions, even if it requires a small amount of initial custom cutting by the supplier.

- If your primary focus is a highly specific part geometry: Plan for a custom order from the outset and communicate your precise dimensional requirements to your supplier.

Ultimately, knowing the landscape of standard sizes empowers you to make smarter design and purchasing decisions from the very beginning.

Summary Table:

| Material Type | Standard Size (Planar/Diameter) | Common Thickness/Diameter Range |

|---|---|---|

| PTFE Sheet | 48" x 48" (1200mm x 1200mm) | 0.031" (0.8mm) to 4" (100mm) |

| PTFE Rod | N/A (Defined by Diameter) | 0.125" (3mm) to 8" (200mm) |

Need precision PTFE components for your semiconductor, medical, or industrial application?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, labware, and custom components. Whether you require a standard size for rapid prototyping or a fully custom fabrication from prototype to high-volume production, our expertise ensures your parts meet the exact specifications for performance and durability.

Let us help you optimize your design and minimize waste. Contact our team today to discuss your PTFE requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the thermal properties of FR4 PCB material? Master Heat Management for Reliable Circuits

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the key properties of PTFE that make it suitable for high-performance applications? Unlock Extreme Performance

- How significant is PTFE in engineering materials? Unlock Unmatched Performance for Demanding Applications

- What is the temperature range that PTFE can tolerate? Ensure Your Application's Thermal Safety

- What construction applications benefit from PTFE's properties? Solve Critical Engineering Challenges

- What are the safety considerations when using PTFE at high temperatures? Managing Decomposition Risks

- What are the benefits of glass-filled PTFE? Achieve Superior Strength & Wear Resistance