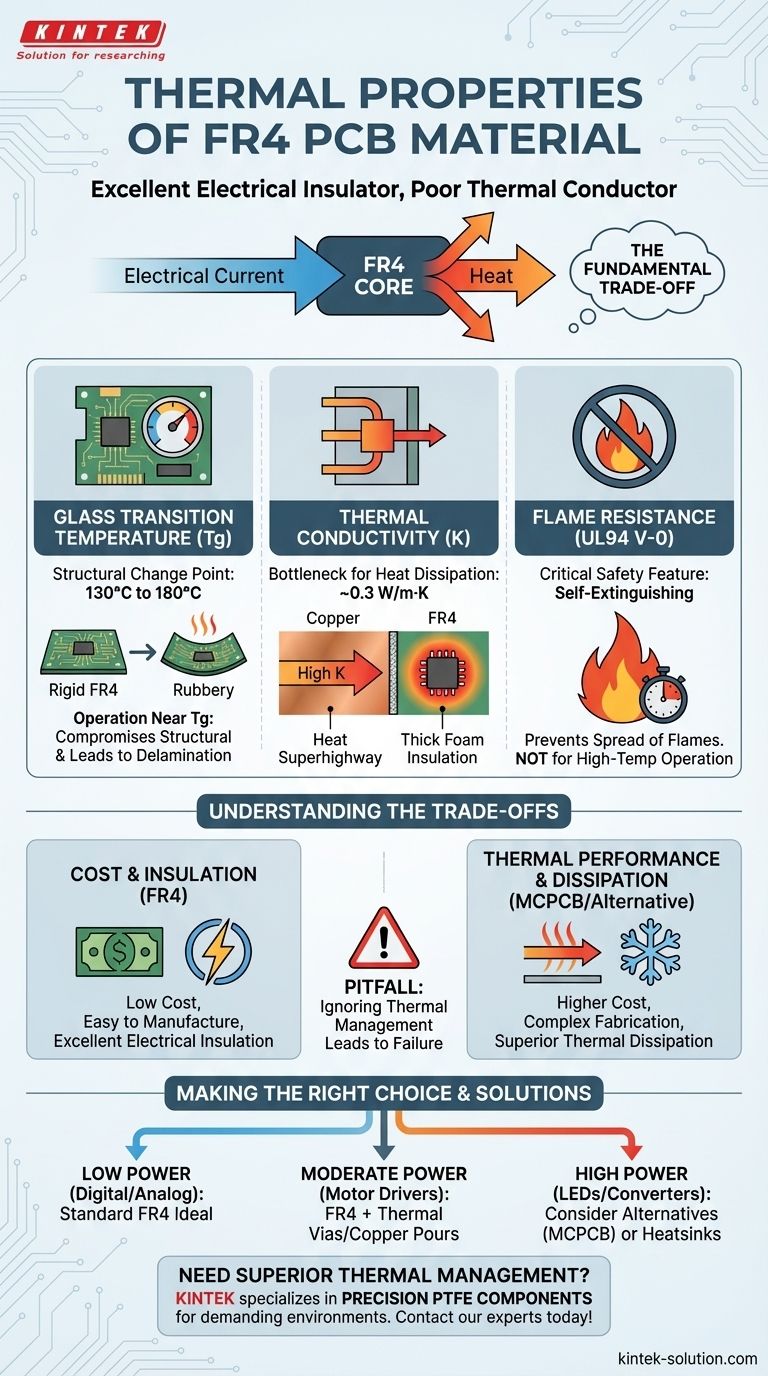

At its core, FR4 is an excellent electrical insulator but a poor thermal conductor. Its primary thermal properties include a glass transition temperature (Tg) between 130°C and 180°C, a very low thermal conductivity of approximately 0.3 W/m·K, and a UL94 V-0 flame-resistance rating. These characteristics make it a cost-effective standard for most electronics but create significant challenges for high-power applications.

The fundamental trade-off with FR4 is that the same property making it a great electrical insulator also makes it a thermal barrier. Understanding this is the key to designing reliable circuits that manage heat effectively.

Deconstructing FR4's Key Thermal Characteristics

To properly apply FR4, you must understand how each of its thermal properties impacts circuit performance and reliability. These are not just numbers on a datasheet; they are critical design constraints.

Glass Transition Temperature (Tg): The Point of Structural Change

The glass transition temperature (Tg) is the point where the rigid, glass-like epoxy resin within the FR4 begins to soften and become rubbery. It is not a melting point, but a critical change in material state.

For most standard FR4, this occurs around 130°C to 180°C. Operating a PCB near or above its Tg compromises its structural and dimensional integrity, which can lead to delamination and circuit failure over time.

Thermal Conductivity (K): The Bottleneck for Heat Dissipation

Thermal conductivity measures how effectively a material transfers heat. FR4 has a very low value of around 0.3 W/m·K, making it a thermal insulator.

Think of it this way: the copper in your traces is a heat superhighway, while the FR4 substrate is like a thick wall of foam insulation. This extreme difference is why heat gets trapped under high-power components, creating dangerous "hot spots."

Flame Resistance (UL94 V-0): A Critical Safety Feature

The UL94 V-0 rating is a safety certification. It signifies that if the material catches fire, it will self-extinguish within a short period, preventing the spread of flames.

It is crucial to understand that this is purely a safety measure against fire. It does not mean FR4 can operate reliably at high temperatures—it only means it is designed not to sustain a flame in a catastrophic failure.

Understanding the Trade-offs

Choosing a PCB material is always an exercise in balancing cost, performance, and manufacturability. The widespread use of FR4 is a direct result of these trade-offs.

Cost vs. Thermal Performance

FR4's primary advantage is its low cost and ease of manufacturing. It is rigid, strong, and simple to drill and process, making it the most economical choice for the vast majority of electronic devices.

Materials with high thermal conductivity, such as metal-core PCBs (MCPCB), are significantly more expensive and complex to fabricate. This cost is only justified when thermal performance is a non-negotiable requirement.

Electrical Insulation vs. Thermal Dissipation

The low conductivity that makes FR4 a poor heat manager is precisely what makes it an excellent electrical insulator. It effectively prevents current from leaking between layers and traces.

This creates the central conflict in power electronics design: the need to isolate voltages while simultaneously removing waste heat through the same substrate material.

The Pitfall of Ignoring Thermal Management

The most common mistake is using standard FR4 in a power-intensive design without a dedicated thermal strategy. This leads to components exceeding their safe operating temperatures, drastically reducing their lifespan and the reliability of the entire product.

For any circuit dissipating significant heat, you cannot rely on the FR4 itself. You must implement thermal management solutions like heatsinks, thermal vias, or active cooling to bypass the material's insulating properties.

Making the Right Choice for Your Design

Your application's thermal load is the single most important factor in determining if FR4 is the right choice and how it should be implemented.

- If your primary focus is low-power digital logic or analog signals: Standard FR4 is the ideal, cost-effective choice as heat generation is minimal.

- If your primary focus is moderate power with localized hot spots (e.g., motor drivers, small regulators): FR4 is viable, but you must design in thermal management like thermal vias and copper pours to shuttle heat away from components.

- If your primary focus is high-power applications (e.g., high-brightness LEDs, power converters): Standard FR4 is often unsuitable, and you should strongly consider alternatives like metal-core PCBs or a robust strategy with external heatsinks.

Ultimately, you must treat FR4 as a thermal insulator and design your board to actively manage heat, rather than expecting the material to do it for you.

Summary Table:

| Property | Value / Rating | Key Implication for Design |

|---|---|---|

| Thermal Conductivity | ~0.3 W/m·K | Poor heat conductor; acts as a thermal insulator, creating hot spots. |

| Glass Transition Temp (Tg) | 130°C - 180°C | Structural integrity is compromised if operated near or above this temperature. |

| Flame Resistance | UL94 V-0 | Self-extinguishing for safety, but does not indicate high-temperature operational reliability. |

Need high-performance PTFE components for superior thermal management? FR4's limitations highlight the need for materials that excel in demanding thermal and electrical environments. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact components you need for reliability and performance. Let's solve your thermal challenges together—contact our experts today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers