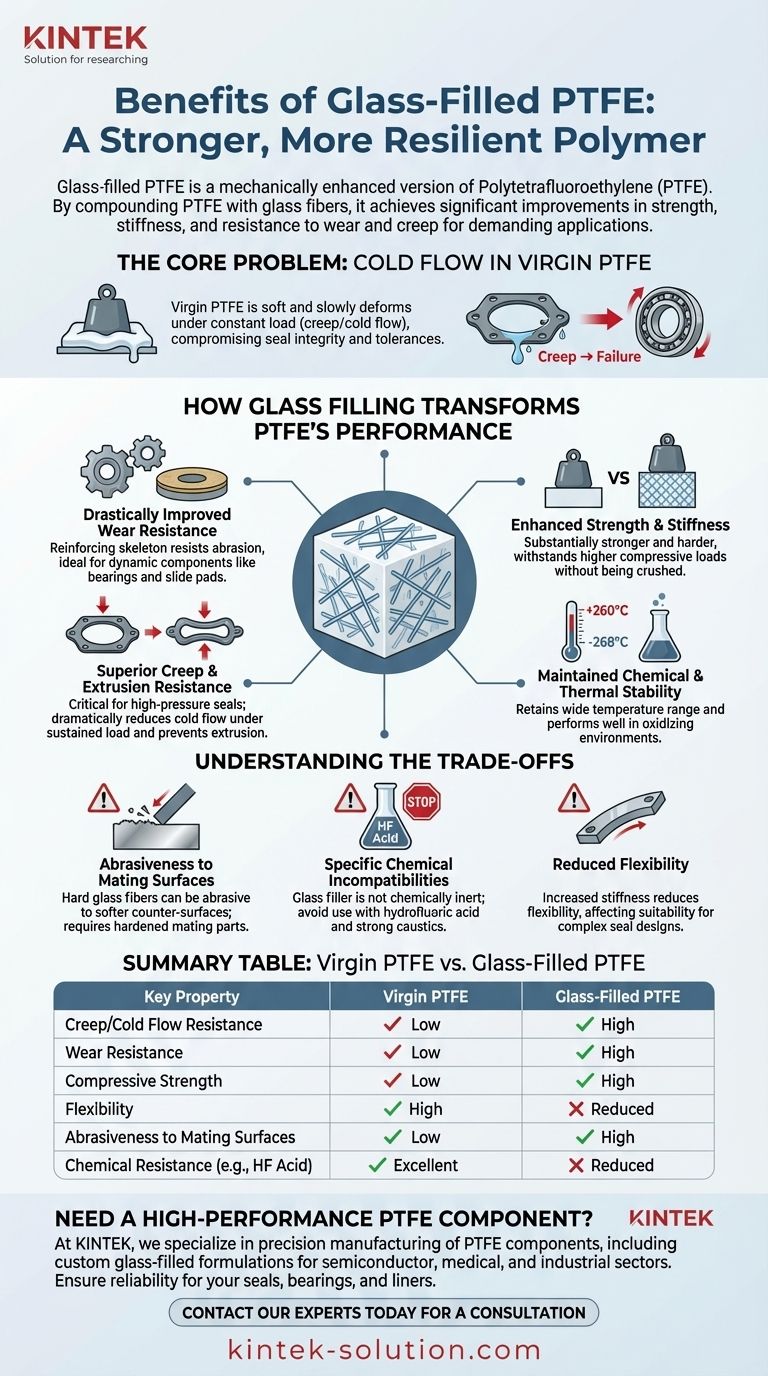

In short, glass-filled PTFE is a mechanically enhanced version of a high-performance polymer. By compounding Polytetrafluoroethylene (PTFE) with glass fibers, the material gains significant improvements in strength, stiffness, and resistance to wear and creep. This makes it far more suitable for demanding structural and sealing applications where virgin PTFE would fail.

The fundamental reason to choose glass-filled PTFE is to overcome the inherent softness and tendency of virgin PTFE to deform under load—a phenomenon known as "creep" or "cold flow." By reinforcing the polymer matrix, glass fibers create a more structurally robust material for components like seals, bearings, and gaskets that must maintain their shape under pressure.

The Core Problem with Virgin PTFE: Cold Flow

What is "Creep" or "Cold Flow"?

Virgin PTFE is renowned for its low friction and chemical inertness, but it is also an exceptionally soft material. When subjected to a constant load, especially compressive force, it will slowly and permanently deform.

This deformation, known as creep or cold flow, can occur even at room temperature and is a primary limiting factor for using PTFE in mechanical applications.

The Impact on Performance

This tendency to deform compromises the integrity of critical components. For example, a gasket made from virgin PTFE may lose its sealing pressure over time as the material flows, leading to leaks.

In bearings or structural parts, this dimensional instability results in a loss of critical tolerances and eventual failure of the assembly.

How Glass Filling Transforms PTFE's Performance

Adding glass fiber, typically in concentrations from 5% to 40%, creates a composite material that directly counteracts the weaknesses of virgin PTFE while retaining most of its key advantages.

Drastically Improved Wear Resistance

The glass fibers act as a reinforcing skeleton within the soft PTFE matrix. This structure is significantly more resistant to abrasion and wear, making it ideal for self-lubricating bearings, slide pads, and other dynamic components.

Enhanced Strength and Stiffness

Compared to its unfilled counterpart, glass-filled PTFE is substantially stronger, harder, and more rigid. This increased compressive strength ensures the material can withstand higher loads without being crushed.

Superior Creep and Extrusion Resistance

This is the most critical benefit. The glass fibers physically obstruct the PTFE polymer chains from moving, dramatically reducing cold flow under sustained load.

This property is essential for high-pressure seals and gaskets, where the material must resist being extruded out of its designated gap.

Maintained Chemical and Thermal Stability

Glass-filled PTFE retains the exceptionally wide operating temperature range of virgin PTFE, from -268°C to +260°C (-450°F to +500°F). It also performs very well in oxidizing environments.

Understanding the Trade-offs

No material enhancement comes without compromise. While glass-filled PTFE solves many problems, it introduces new considerations.

Abrasiveness to Mating Surfaces

The hard glass fibers that provide wear resistance can also be abrasive to softer counter-surfaces, such as aluminum or softer steels. This is a critical design consideration for dynamic seals and bearings, often requiring the use of hardened mating surfaces.

Specific Chemical Incompatibilities

While PTFE is famously inert, the glass filler is not. Glass-filled PTFE should not be used with chemicals known to attack glass, most notably hydrofluoric acid and strong caustics (alkalis).

Reduced Flexibility

The increase in stiffness and hardness naturally means a reduction in flexibility compared to virgin PTFE. This may affect its suitability for certain seal designs that require high compliance to function correctly.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with the demands of the operating environment.

- If your primary focus is sealing in high-pressure systems: Glass-filled PTFE provides the necessary creep and extrusion resistance that virgin PTFE lacks.

- If your primary focus is a low-friction bearing or slide surface: Choose glass-filled PTFE for its superior wear resistance, but ensure the mating surface is hard enough to resist abrasion.

- If your primary focus is chemical compatibility with strong caustics or hydrofluoric acid: You must avoid glass-filled PTFE and opt for virgin PTFE or another suitably filled grade.

- If your primary focus is maximum flexibility for a complex seal: Virgin PTFE may be a better choice, provided the pressure and load are low enough to prevent cold flow.

Ultimately, selecting glass-filled PTFE is a strategic decision to gain mechanical stability where the unique properties of virgin PTFE are desired but its inherent softness is a liability.

Summary Table:

| Key Property | Virgin PTFE | Glass-Filled PTFE |

|---|---|---|

| Creep/Cold Flow Resistance | Low | High |

| Wear Resistance | Low | High |

| Compressive Strength | Low | High |

| Flexibility | High | Reduced |

| Abrasiveness to Mating Surfaces | Low | High |

| Chemical Resistance (e.g., HF Acid) | Excellent | Reduced |

Need a high-performance PTFE component that won't fail under pressure?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom glass-filled formulations. We understand the critical balance between chemical resistance, mechanical strength, and wear performance required in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need prototypes or high-volume production, our expertise ensures your seals, bearings, liners, and labware are engineered for reliability. Let us help you select the right material and fabricate a solution that meets your exact specifications.

Contact our experts today for a consultation on your custom PTFE needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech