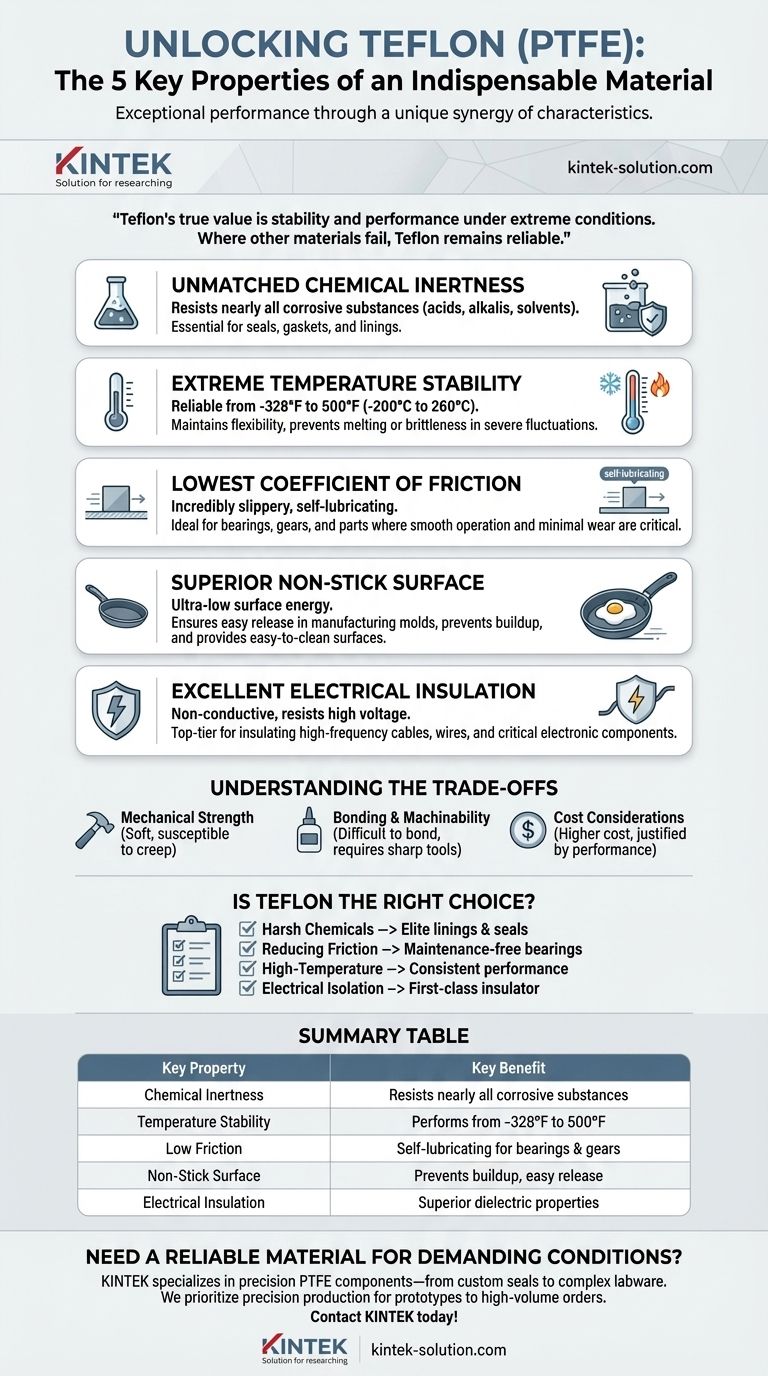

At its core, Teflon (PTFE) stands out due to a unique combination of five key properties: an exceptionally non-stick surface, high heat resistance, near-total chemical inertness, an extremely low coefficient of friction, and excellent electrical insulation. It is this powerful synergy of characteristics, rather than a single attribute, that makes it an indispensable material in demanding industrial, mechanical, and electrical applications.

The true value of Teflon is its ability to maintain stability and performance under extreme conditions. Where other materials would degrade, react, or fail, Teflon remains reliable, making it a problem-solver for the most challenging engineering environments.

The Core Properties Explained

To understand Teflon's versatility, we must look at how each of its primary characteristics functions and contributes to its overall performance.

Unmatched Chemical Inertness

Teflon is resistant to nearly all corrosive substances, including strong acids, alkalis, and aggressive solvents. This chemical stability means it will not degrade or react when exposed to harsh materials.

This property makes it an essential material for seals, gaskets, and linings in chemical processing, where material integrity is paramount for safety and operational longevity.

Extreme Temperature Stability

Teflon performs reliably across an exceptionally wide temperature range, from cryogenic lows of -328°F (-200°C) up to a high of 500°F (260°C).

Unlike most plastics that become brittle in the cold or melt in the heat, Teflon maintains its flexibility and structural properties, ensuring consistent performance in environments with severe temperature fluctuations.

The Lowest Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any solid material, making it incredibly slippery. This is often compared to the slipperiness of wet ice on wet ice.

This property allows it to function as a self-lubricating material. It is a superior choice for bearings, gears, and other mechanical parts where smooth operation and minimal wear are critical, often eliminating the need for external lubricants.

Superior Non-Stick Surface

Famously known for its use in cookware, Teflon's anti-adhesive quality is a significant industrial advantage. Its surface energy is so low that very few substances will stick to it.

This ensures easy release in manufacturing molds, prevents buildup in fluid handling systems, and provides easy-to-clean surfaces in a variety of applications.

Excellent Electrical Insulation

Teflon is an outstanding electrical insulator with a very low dielectric constant and dissipation factor. It does not conduct electricity and resists high voltages effectively.

These electrical properties make it a top-tier choice for insulating high-frequency cables, wires, and critical electronic components where signal integrity and safety are non-negotiable.

Understanding the Trade-offs

No material is perfect for every situation. Acknowledging Teflon's limitations is key to using it effectively.

Mechanical Strength and Wear

While durable in terms of chemical and thermal stability, Teflon is a relatively soft material. It can be susceptible to "creep," or slow deformation under a sustained load.

It is not a structural material and has lower abrasion resistance compared to harder plastics, making it unsuitable for high-load, high-wear applications without reinforcement.

Bonding and Machinability

The same non-stick properties that make Teflon so useful also make it very difficult to bond to other surfaces with conventional adhesives. Special surface treatments are required to achieve a strong bond.

While it can be machined, its softness requires sharp tools and specific techniques to prevent deformation and ensure precise results.

Cost Considerations

PTFE is a high-performance polymer, and its manufacturing process makes it more expensive than common commodity plastics like polyethylene or nylon.

The cost is justified by its unique performance in extreme environments where other materials would fail, but it may be overkill for less demanding applications.

Is Teflon the Right Choice for Your Application?

Choosing Teflon depends entirely on whether its unique strengths align with the primary demands of your project.

- If your primary focus is performance in harsh chemical environments: Teflon's near-total inertness makes it an elite and reliable choice for linings, seals, and fluid transport.

- If your primary focus is reducing friction in mechanical systems: Its self-lubricating properties are ideal for creating low-wear, maintenance-free bearings and sliding components.

- If your primary focus is high-temperature stability: Its exceptionally wide operating range ensures consistent performance where most other plastics would fail.

- If your primary focus is electrical isolation: Its superior dielectric properties make it a first-class insulator for demanding electronic and high-frequency applications.

Ultimately, Teflon is the premier material for applications where reliability in the face of chemical, thermal, or electrical stress is the most critical factor.

Summary Table:

| Key Property | Key Benefit |

|---|---|

| Chemical Inertness | Resists nearly all corrosive substances, ideal for seals and linings. |

| Temperature Stability | Performs from -328°F to 500°F (-200°C to 260°C). |

| Low Friction | Self-lubricating for bearings and gears, reducing wear. |

| Non-Stick Surface | Prevents buildup and ensures easy release and cleaning. |

| Electrical Insulation | Superior dielectric properties for high-frequency cables and components. |

Need a reliable material for demanding conditions?

Teflon's unique properties make it the ideal solution for challenging applications in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in manufacturing precision PTFE components—from custom seals and liners to complex labware.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact part you need for peak performance.

Contact KINTEK today to discuss your specific requirements and see how our PTFE expertise can benefit your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the most popular and processed forms of PTFE materials? A Guide to Rods, Tubes, Sheets & Tapes

- What are the main advantages of PTFE gaskets over ordinary rubber gaskets? Superior Chemical & Thermal Resistance

- What is the typical temperature range for PTFE diaphragms? Key Factors for Optimal Performance

- Why is the manufacturing cost of PTFE processing machines high? The Engineering Behind High-Performance Polymer Processing

- What are the characteristics of unidirectional PTFE lip seals? Superior One-Way Sealing for Demanding Applications

- What are the common issues hindering the adoption of PTFE wear plates? Overcome These 4 Key Barriers

- Why is PTFE considered the best material for heavy-duty cable liners? Achieve Superior Reliability & Efficiency

- What factors should be considered when choosing between PTFE lined and hard seal butterfly valves? Ensure Optimal Performance and Safety