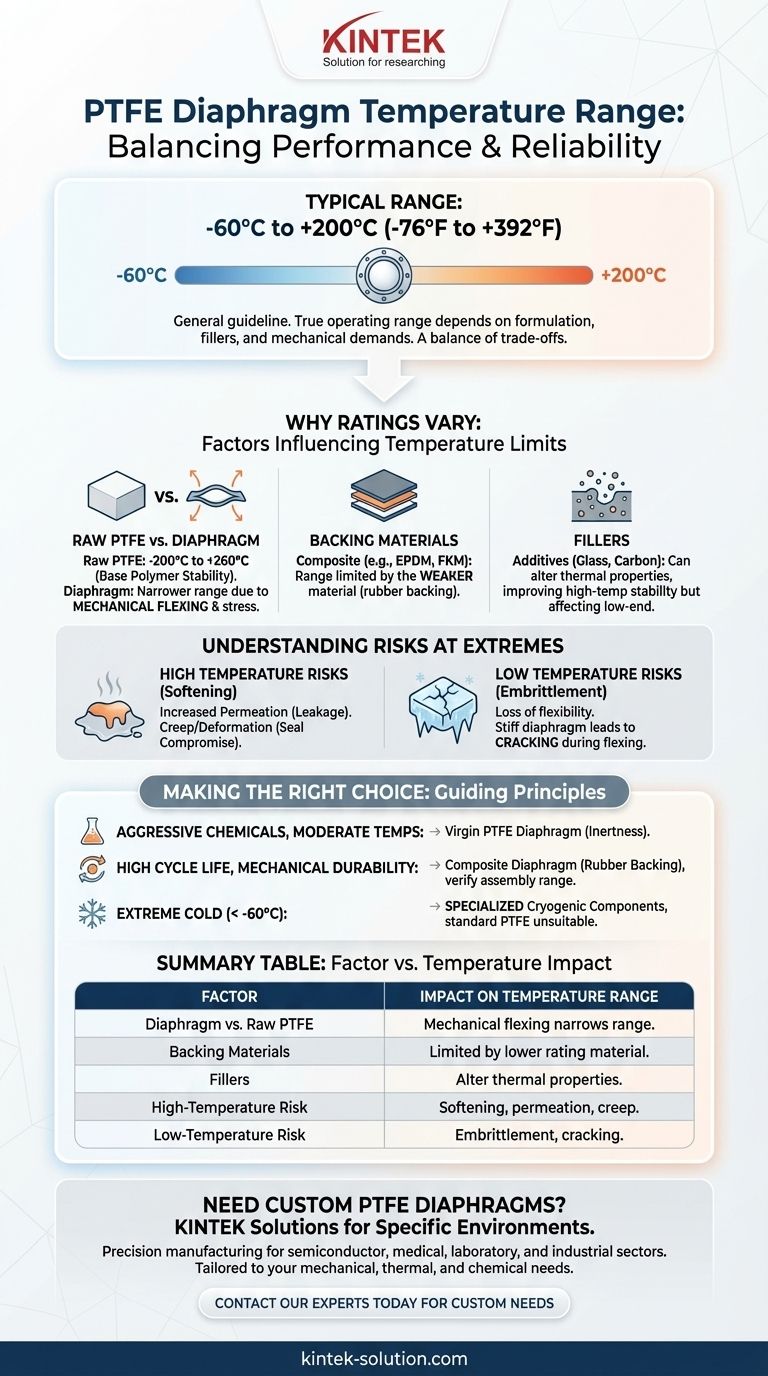

The typical temperature range for a PTFE diaphragm is approximately -60°C to +200°C (-76°F to +392°F). However, this is a general guideline. The true operating range depends heavily on the specific formulation, the presence of fillers, and the mechanical demands of the application.

The stated temperature range for any component is a balance of trade-offs. While the raw PTFE polymer can endure a wider temperature spectrum, a diaphragm's need for mechanical flexibility significantly narrows its practical, reliable operating window.

Why Temperature Ratings for PTFE Vary

You will often see different temperature ratings for PTFE. A raw block of PTFE has different limits than a complex, dynamic part like a diaphragm. Understanding these distinctions is critical for selecting the right material.

Raw PTFE vs. a Finished Diaphragm

The base PTFE polymer boasts a very wide service range, often cited from -200°C to +260°C (-328°F to +500°F). This represents the material's fundamental thermal stability before it begins to degrade or become excessively brittle.

However, a diaphragm must flex repeatedly. This mechanical stress makes it more susceptible to failure at extreme temperatures, leading to a more conservative and realistic operating range.

The Impact of Backing Materials

Many high-performance diaphragms are composites, featuring a PTFE layer bonded to a more flexible rubber backing (like EPDM or FKM).

This design enhances strength and cycle life. Crucially, the operating temperature of the composite diaphragm is now limited by the weaker material, which is almost always the rubber backing.

The Role of Fillers

Fillers like glass, carbon, or bronze are added to PTFE to improve properties such as wear resistance, stiffness, and resistance to creep (deformation under load).

These additives can alter the thermal properties of the final product. While they may improve stability at high temperatures, they can sometimes reduce performance at the low end of the spectrum.

Understanding the Trade-offs at Temperature Extremes

Operating a PTFE diaphragm near its temperature limits introduces risks that can lead to premature failure. It's not just about survival; it's about performance and reliability.

Risks at High Temperatures

As PTFE approaches its upper limit, it begins to soften. This can lead to two primary issues:

- Increased Permeation: The material becomes more porous, potentially allowing minute leakage of media.

- Creep/Deformation: Under pressure, the diaphragm may permanently deform, compromising its seal and function.

Risks at Low Temperatures

The most significant risk at low temperatures is embrittlement. As PTFE gets colder, it loses its signature flexibility.

For a diaphragm, which relies on its ability to flex, this is a critical failure point. A stiff, brittle diaphragm is highly susceptible to cracking, especially during pressure changes or mechanical actuation. This is the primary reason a diaphragm's low-temperature limit is much higher than that of the raw polymer.

Making the Right Choice for Your Application

Always prioritize the manufacturer's data sheet for the specific part you are considering. Use the following principles to guide your decision-making process.

- If your primary focus is handling aggressive chemicals at moderate temperatures: A standard, virgin PTFE diaphragm is often the ideal choice for its unparalleled chemical inertness.

- If your primary focus is high cycle life and mechanical durability: A composite diaphragm with a rubber backing will likely offer superior performance, but you must verify that the entire assembly's temperature range meets your needs.

- If your primary focus is operation in extreme cold (below -60°C): A standard PTFE diaphragm is likely unsuitable. You must seek out specialized components engineered specifically for cryogenic service.

Ultimately, you must match the component's verified specifications to the full range of thermal and mechanical stresses within your application.

Summary Table:

| Factor | Impact on Temperature Range |

|---|---|

| Diaphragm vs. Raw PTFE | Mechanical flexing narrows the range compared to the base polymer. |

| Backing Materials (e.g., EPDM) | The composite's range is limited by the material with the lower rating. |

| Fillers (e.g., Glass, Carbon) | Can alter thermal properties, often improving high-temp stability. |

| High-Temperature Risk | Softening can lead to permeation and permanent deformation (creep). |

| Low-Temperature Risk | Embrittlement can cause cracking during flexing. |

Need a PTFE Diaphragm Engineered for Your Specific Temperature and Chemical Requirements?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom diaphragms for the semiconductor, medical, laboratory, and industrial sectors. We understand that your application's success depends on more than just a standard temperature rating—it requires a component tailored to your exact mechanical, thermal, and chemical environment.

Let us help you achieve optimal performance and reliability. Contact our experts today to discuss your custom PTFE diaphragm needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications