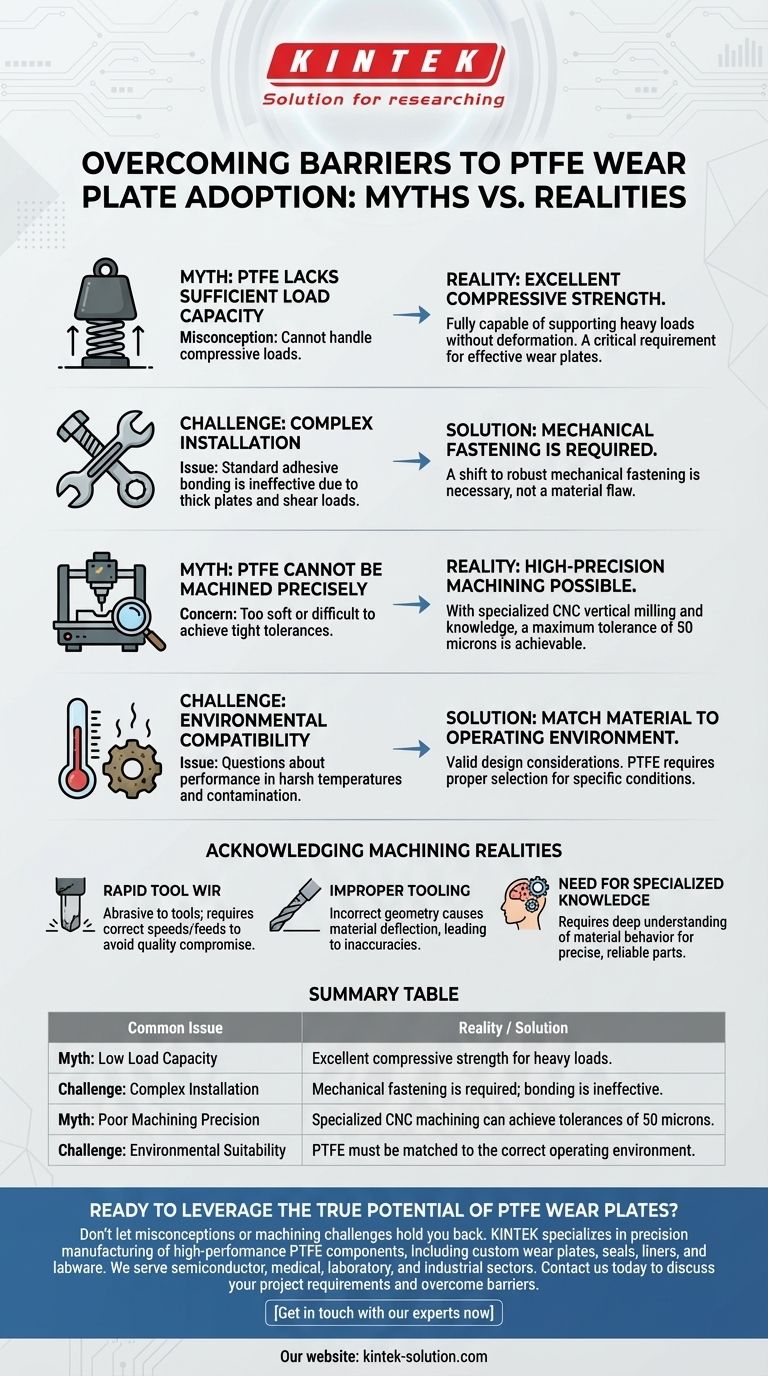

Four primary concerns often hinder the adoption of PTFE wear plates in industrial applications. These issues typically revolve around complex installation methods, incorrect assumptions about the material's strength, challenges in precision machining, and its suitability for specific operating environments.

The most significant barriers to using PTFE wear plates are not fundamental flaws in the material, but rather misconceptions about its capabilities and a lack of specialized knowledge regarding its installation and fabrication.

Deconstructing the Barriers to PTFE Adoption

Understanding these common concerns is the first step to overcoming them. Most perceived limitations are, in fact, engineering challenges that have well-established solutions.

Myth: PTFE Lacks Sufficient Load Capacity

A frequent misconception is that PTFE, being a polymer, cannot handle the compressive loads required in wear plate applications.

This view underestimates the material's properties. PTFE possesses excellent compressive strength, making it fully capable of supporting heavy loads without deforming, a critical requirement for effective wear plates.

Challenge: Complex Installation

Engineers often face difficulties when trying to install PTFE wear plates using conventional methods.

Because wear plates are relatively thick and are subjected to significant shear loads, standard adhesive bonding is ineffective. This is a genuine limitation of bonding, not the material, requiring a shift in installation strategy to mechanical fastening.

Myth: PTFE Cannot Be Machined Precisely

There is a concern that PTFE is too soft or difficult to work with to achieve the tight tolerances needed for industrial parts.

While PTFE does require specialized handling, it can be machined to a high degree of accuracy. Using a CNC vertical milling centre, it's possible to achieve a maximum tolerance of 50 microns, which is more than acceptable for the vast majority of industrial applications.

Challenge: Environmental Compatibility

Questions often arise about PTFE's performance in harsh conditions, specifically regarding temperature and contamination.

Concerns about temperature resistance and the potential for dirt buildup in machined grooves are valid design considerations. However, this simply means PTFE must be matched to the correct operating environment, a standard step in any material selection process.

Acknowledging the Machining Realities

While the precision myth is false, machining PTFE does present real-world challenges that must be managed by an experienced fabricator. Ignoring these can lead to dimensional inaccuracies and failed components.

The Risk of Rapid Tool Wear

PTFE can be abrasive to cutting tools, especially when machined at incorrect speeds or feed rates. This leads to rapid tool wear, which can compromise the quality and consistency of the finished parts if not properly managed.

The Impact of Improper Tooling

Using tools with incorrect geometries is a common mistake. This can cause the material to deflect or deform under pressure from the tool, rather than being cut cleanly, resulting in dimensional inaccuracies.

The Need for Specialized Knowledge

Successfully machining PTFE is not the same as machining metals or other plastics. It requires a deep understanding of the material's behavior to select the right tools, speeds, and techniques to produce precise, reliable parts.

Making an Informed Decision on PTFE

By addressing these common points of friction, you can evaluate PTFE wear plates based on their true engineering merits.

- If your primary focus is high load capacity: Do not discount PTFE based on misconceptions; its compressive strength is a key advantage in many applications.

- If your primary focus is ease of installation: Recognize that robust mechanical fastening is required, as bonding is not a viable option for PTFE wear plates.

- If your primary focus is tight tolerances: Partner with a fabricator experienced in PTFE, as specialized CNC machining is necessary to overcome material challenges and ensure precision.

By separating myth from engineering reality, you can accurately assess if PTFE's unique benefits are the right fit for your challenge.

Summary Table:

| Common Issue | Reality / Solution |

|---|---|

| Myth: Low Load Capacity | PTFE has excellent compressive strength for heavy loads. |

| Challenge: Complex Installation | Mechanical fastening is required; bonding is ineffective. |

| Myth: Poor Machining Precision | Specialized CNC machining can achieve tolerances of 50 microns. |

| Challenge: Environmental Suitability | PTFE must be matched to the correct operating environment. |

Ready to leverage the true potential of PTFE wear plates?

Don't let misconceptions or machining challenges hold you back. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom wear plates, seals, liners, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, providing expert solutions from prototype to high-volume production. Our deep material knowledge ensures your PTFE parts are machined accurately and perform reliably in your specific application.

Contact us today to discuss your project requirements and discover how we can help you overcome these common barriers.

Get in touch with our experts now

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support