To put it simply, a unidirectional Polytetrafluoroethylene (PTFE) lip seal is a high-performance component designed for applications requiring sealing in only one direction. Its key characteristics are a specialized lip design that prevents backflow, combined with the inherent material strengths of PTFE: an extremely low coefficient of friction, the ability to withstand a vast range of temperatures and pressures, and near-universal chemical resistance.

The core value of a unidirectional PTFE lip seal is its ability to provide reliable one-way sealing in demanding dynamic environments—such as high-speed shafts or chemically aggressive systems—where traditional elastomeric seals would quickly degrade and fail.

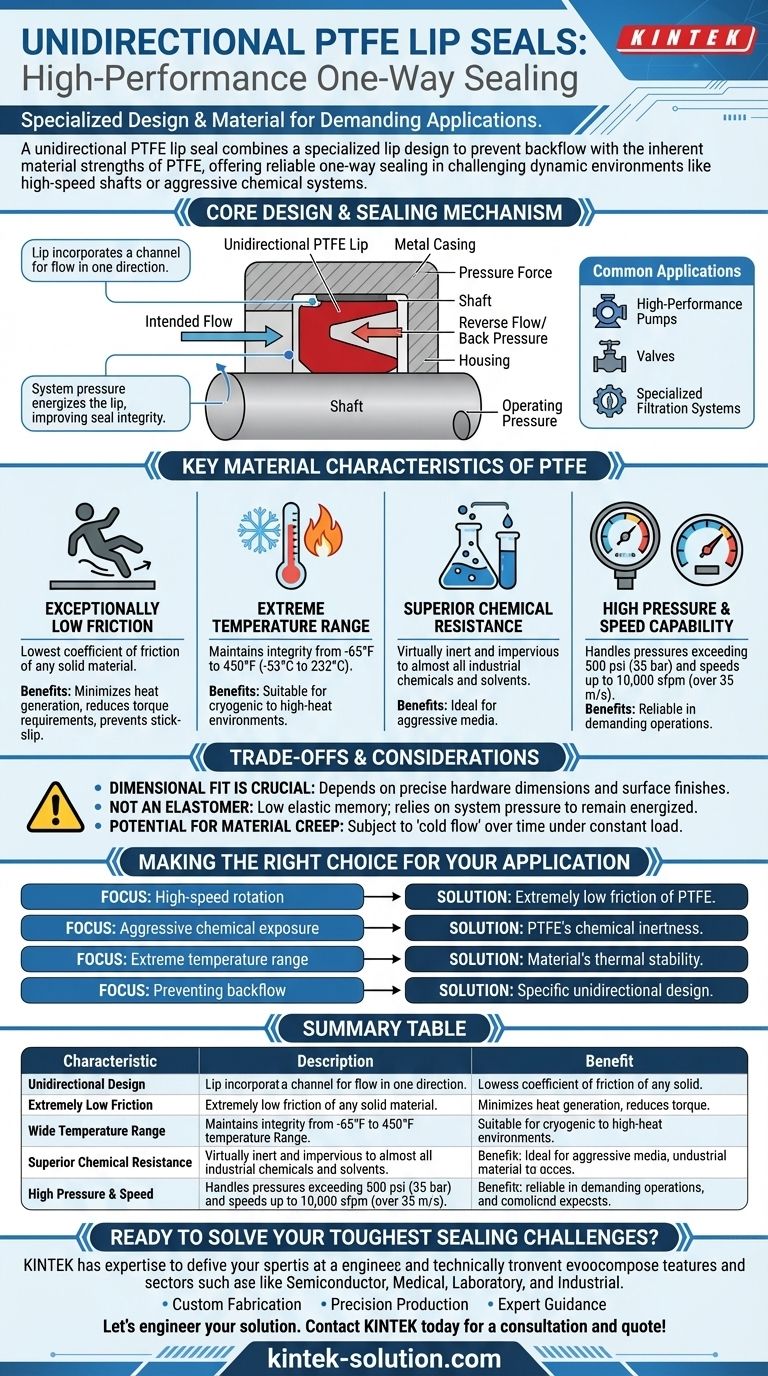

Core Design and Sealing Mechanism

A seal's effectiveness is determined by its design and material. Unidirectional PTFE seals excel by combining a purpose-built geometry with a uniquely capable polymer.

The Unidirectional Lip

The seal features a distinct, thick lip on its interior diameter. This lip incorporates a narrow channel engineered to allow media (fluid or gas) to pass in the intended direction while creating a robust barrier against any reverse flow or back pressure.

How It Works

The seal's lip fastens against the shaft, and its metal casing is secured in the housing. The system's operating pressure helps energize the lip, forcing it more tightly against the shaft to improve the seal in the intended direction. This design ensures that as pressure increases, the sealing integrity also increases.

Common Applications

Due to their specific function, these seals are frequently specified for equipment where controlling flow direction is critical. This includes high-performance pumps, valves, and specialized filtration systems.

Key Material Characteristics of PTFE

The choice of PTFE is central to the seal's performance. This fluoropolymer provides a combination of properties that make it ideal for challenging industrial applications.

Exceptionally Low Friction

PTFE has the lowest known coefficient of friction of any solid material. This is critical for dynamic seals on rotating shafts, as it minimizes heat generation, reduces torque requirements, and prevents stick-slip issues.

Extreme Temperature Range

These seals maintain their integrity and performance across an exceptionally wide thermal window, typically from -65°F to 450°F (-53°C to 232°C). This stability makes them suitable for both cryogenic and high-heat environments.

Superior Chemical Resistance

PTFE is virtually inert and impervious to attack from almost all industrial chemicals and solvents. This makes it the default choice for sealing in aggressive media where other materials would corrode or swell.

High Pressure and Speed Capability

PTFE lip seals are engineered to handle significant operational demands. They can maintain a tight seal at pressures exceeding 500 psi (35 bar) and at surface speeds of up to 10,000 sfpm (over 35 m/s).

Understanding the Trade-offs and Considerations

While powerful, PTFE seals are not a universal solution. Understanding their specific requirements is key to successful implementation.

Dimensional Fit is Crucial

Unlike forgiving elastomeric seals, PTFE is a less compliant plastic. Achieving a reliable seal depends on precise hardware dimensions and surface finishes. Any shaft imperfections or housing irregularities can compromise sealing performance.

Not an Elastomer

PTFE has very little "elastic memory" compared to rubber. It will not spring back into shape as readily, which means it relies more on system pressure to remain energized. Proper design and installation are critical to compensate for this characteristic.

Potential for Material Creep

As a thermoplastic, PTFE can be subject to "cold flow," or creep, meaning it can slowly deform over time under a constant load. This factor must be accounted for in the engineering and design phase, especially in static applications under high pressure.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its capabilities to your primary operational goal.

- If your primary focus is high-speed rotation: The extremely low friction of PTFE is ideal for minimizing heat generation, wear, and energy loss.

- If your primary focus is aggressive chemical exposure: PTFE's chemical inertness provides a reliable sealing solution where elastomers would certainly fail.

- If your primary focus is an extreme temperature range: The material's thermal stability ensures consistent sealing performance from cryogenic lows to high-heat conditions.

- If your primary focus is preventing backflow in a dynamic system: The specific unidirectional design is engineered precisely for applications like pump outlets or check valves.

By understanding these core characteristics, you can confidently specify unidirectional PTFE lip seals for your most demanding dynamic sealing challenges.

Summary Table:

| Characteristic | Description | Benefit |

|---|---|---|

| Unidirectional Design | Thick lip with a channel for one-way sealing. | Prevents backflow and back pressure. |

| Extremely Low Friction | Lowest coefficient of friction of any solid. | Reduces heat, wear, and energy loss on rotating shafts. |

| Wide Temperature Range | Operates from -65°F to 450°F (-53°C to 232°C). | Suitable for cryogenic to high-heat environments. |

| Superior Chemical Resistance | Virtually inert against most chemicals and solvents. | Ideal for aggressive media where elastomers fail. |

| High Pressure & Speed | Handles pressures >500 psi and speeds up to 10,000 sfpm. | Reliable performance in demanding dynamic applications. |

Ready to Solve Your Toughest Sealing Challenges?

Unidirectional PTFE lip seals from KINTEK are engineered for precision and durability in the most demanding environments. Whether your application is in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures a perfect seal.

We provide:

- Custom Fabrication: From prototypes to high-volume production runs.

- Precision Production: Ensuring optimal performance and a perfect fit for your hardware.

- Expert Guidance: Helping you select the right seal for high-speed, high-temperature, or chemically aggressive systems.

Let's engineer your solution. Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the potential drawbacks of using PTFE for fork bushes? Avoid Costly Stanchion Damage

- How does the shrinkage performance of PTFE gaskets affect their functionality? Ensure a Perfect, Leak-Free Seal

- How do spring energized PTFE seals compare to elastomeric seals in dynamic service? Superior Performance in Extreme Conditions

- What is the general consensus on the effectiveness of plastic fork bushes compared to bronze or steel sleeve bushes?

- What chemically aggressive media are encountered in the oil and gas industry, and how do PTFE seals handle them?

- What are the benefits of porous PTFE? Unlock Superior Filtration and Chemical Resistance

- How do the lightweight and durable properties of PTFE bushes benefit industrial use? Boost Efficiency & Cut Costs

- Why is PTFE a preferred material for medical device seals? Ensuring Safety, Reliability, and Performance