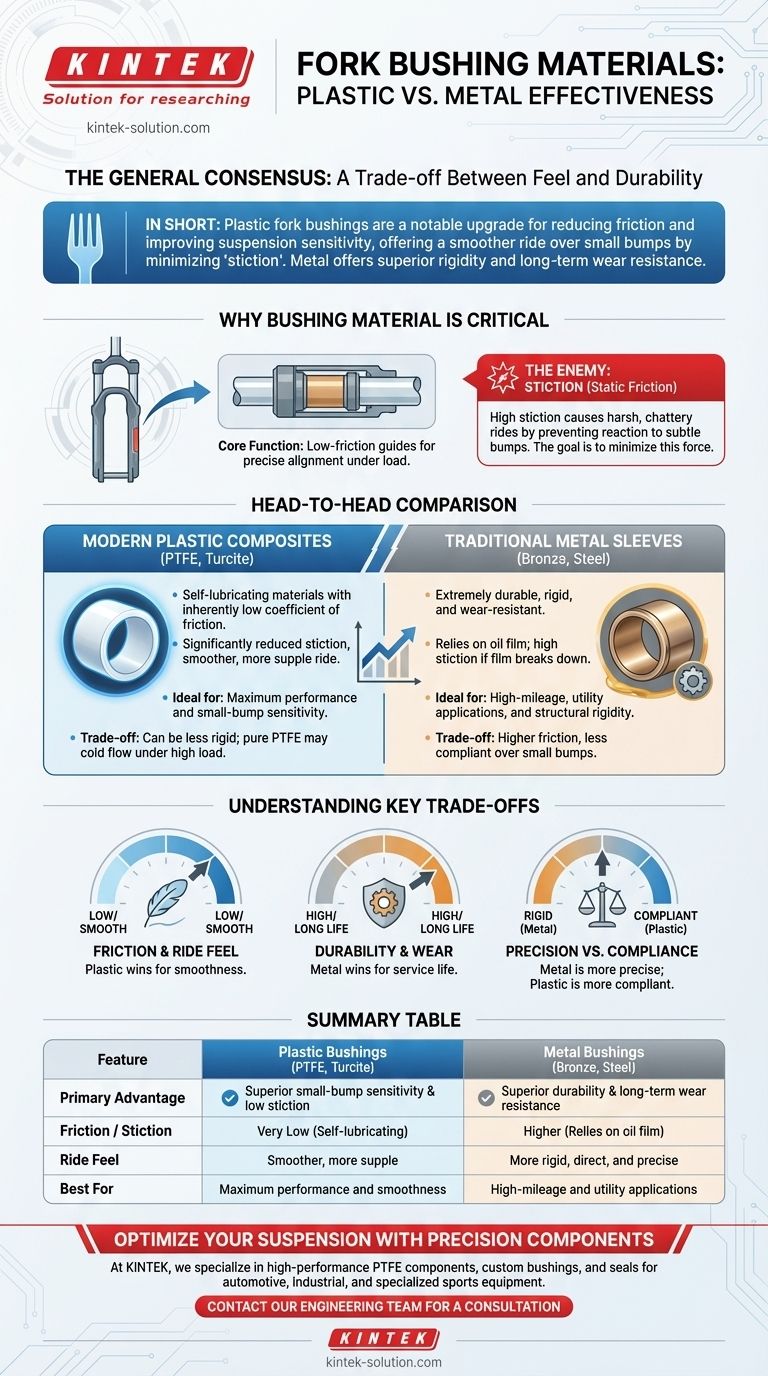

In short, the general consensus is that plastic fork bushings are a notable upgrade over traditional metal sleeves for reducing friction and improving suspension sensitivity. Materials like PTFE and Turcite offer a smoother, more responsive feel, particularly over small bumps where initial friction, or "stiction," is most noticeable.

The choice between plastic and metal fork bushings is a trade-off between performance feel and ultimate durability. Plastic composites excel at providing a low-friction, supple ride, while traditional bronze or steel bushes offer superior rigidity and long-term wear resistance.

Why Bushing Material is Critical for Suspension

The Core Function of a Fork Bushing

Fork bushings are deceptively simple components with a critical job: they act as low-friction guides. They allow the upper and lower fork tubes to slide past each other with minimal resistance while maintaining precise alignment under heavy loads.

The quality of this sliding action directly dictates how well your suspension can react to the terrain.

The Enemy of Performance: "Stiction"

Stiction (static friction) is the initial force required to get the fork moving. High stiction prevents the suspension from reacting to small, subtle bumps, creating a harsh and chattery ride.

The primary goal of upgrading bushings is to minimize this stiction, allowing the fork to become active and absorb impacts more effectively.

A Head-to-Head Comparison: Plastic vs. Metal

Traditional Bronze and Steel Sleeves

Bronze and steel are the classic choices for bushings. Their operation relies entirely on a thin, consistent film of suspension oil for lubrication.

These metal sleeves are extremely durable, rigid, and resistant to wear. They provide a very precise, connected feel. However, if the oil film breaks down, metal-on-metal friction increases dramatically, leading to significant stiction.

Modern Plastic Composites (PTFE, Turcite)

Modern performance bushings are often made from plastic composites like PTFE (Teflon) or proprietary blends like Turcite.

These materials are self-lubricating, meaning they have an inherently low coefficient of friction. They don't rely as heavily on the oil film, which results in a significant reduction in stiction and a noticeably smoother ride.

Understanding the Key Trade-offs

Friction and Ride Feel

For pure smoothness and small-bump sensitivity, plastic is the clear winner. The self-lubricating properties provide an immediate improvement in ride quality that is easy to feel.

Durability and Wear Resistance

In terms of raw durability, metal bushings typically have a longer service life. They are harder and less susceptible to damage from contaminated oil or heavy, repetitive impacts.

Precision vs. Compliance

Metal bushings contribute to overall fork rigidity, offering a very direct and precise feel. Plastic bushings are slightly more compliant, which aids in smoothness but can be perceived as a less direct connection by some highly sensitive riders.

The Downside of Pure PTFE

As the references note, pure PTFE can be too soft for some high-load applications. It can deform or "cold flow" under pressure, leading to a loss of tolerance. This is why stronger, more stable composites like Turcite or graphite-impregnated nylon are often preferred, as they balance low friction with better strength and wear characteristics.

Making the Right Choice for Your Goal

The best material ultimately depends on what you want to achieve with your suspension.

- If your primary focus is maximum performance and smoothness: A high-quality plastic composite bushing like Turcite is the superior choice for reducing stiction.

- If your primary focus is ultimate durability and service life: Traditional bronze or steel sleeve bushings remain an excellent, reliable option, especially for high-mileage or utility applications.

Choosing the right bushing allows you to tailor your suspension's feel directly to your performance needs.

Summary Table:

| Feature | Plastic Bushings (PTFE, Turcite) | Metal Bushings (Bronze, Steel) |

|---|---|---|

| Primary Advantage | Superior small-bump sensitivity & low stiction | Superior durability & long-term wear resistance |

| Friction / Stiction | Very Low (Self-lubricating) | Higher (Relies on oil film) |

| Ride Feel | Smoother, more supple | More rigid, direct, and precise |

| Best For | Maximum performance and smoothness | High-mileage and utility applications |

Ready to Optimize Your Suspension with Precision Components?

The right bushing material is critical for achieving your desired suspension performance. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bushings and seals, for the automotive, industrial, and specialized sports equipment industries.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact performance characteristics you need.

Let's discuss how our materials expertise can enhance your product's performance. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications