In short, Polytetrafluoroethylene (PTFE) is a preferred material for medical seals because of its unparalleled combination of properties. It is exceptionally resistant to the aggressive chemicals and high temperatures used in sterilization, it is biocompatible and inert, and it maintains its physical integrity under extreme operational stress. This makes it uniquely suited for the demanding and safety-critical environment of medical devices.

The core reason for PTFE's dominance in medical sealing is not a single feature, but its unique ability to satisfy three critical, often conflicting, demands simultaneously: absolute patient safety (biocompatibility), operational reliability (chemical and thermal resistance), and high performance (low friction and durability).

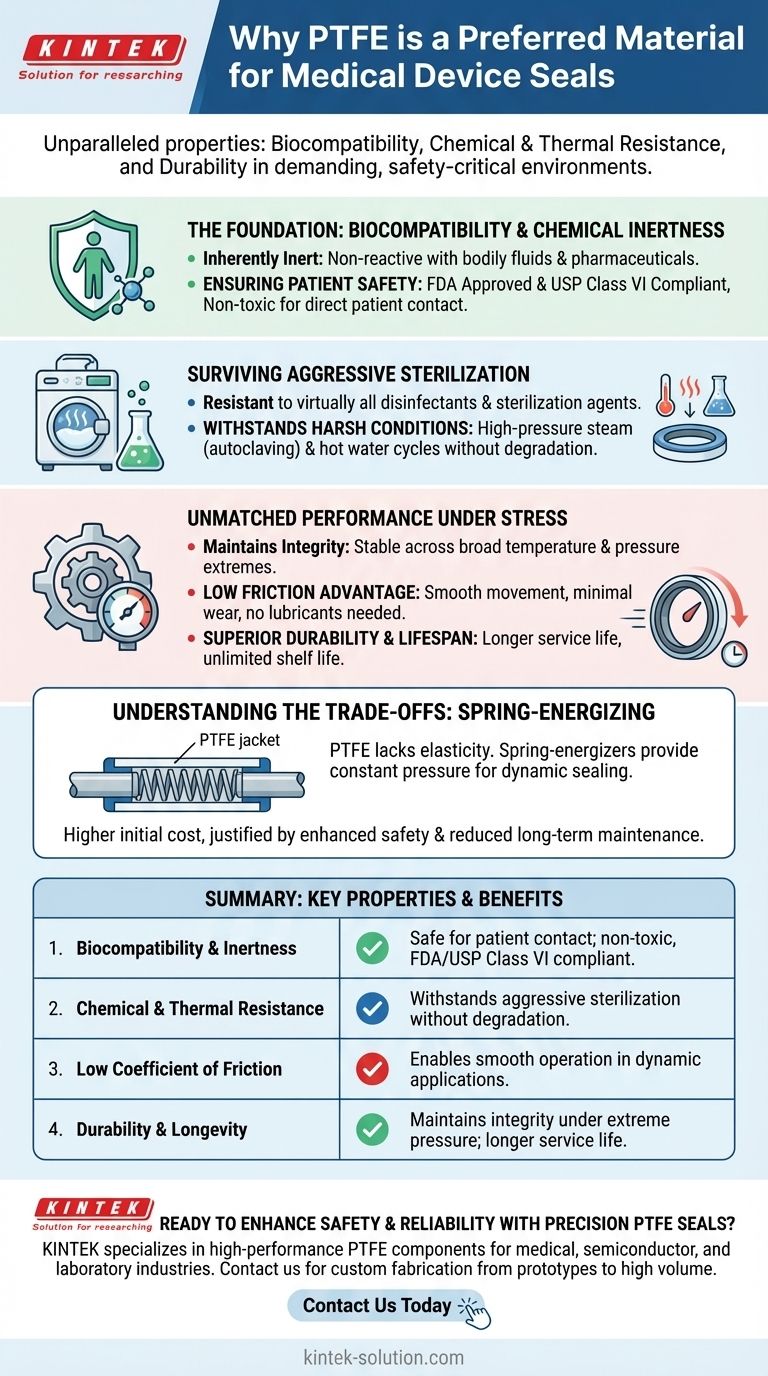

The Foundation: Biocompatibility and Chemical Inertness

The first responsibility of any medical device is to do no harm. PTFE's fundamental chemical nature provides the first layer of assurance.

Ensuring Patient Safety

PTFE is inherently inert, meaning it does not react with bodily fluids, tissues, or sensitive pharmaceuticals.

Select grades of PTFE are FDA approved and USP Class VI compliant, which are rigorous standards confirming the material is non-toxic and suitable for direct patient contact. This non-reactivity is crucial for preventing contamination and adverse patient reactions.

Surviving Aggressive Sterilization

Medical devices must be thoroughly sterilized, a process that involves harsh chemicals, high-pressure steam (autoclaving), and hot water.

PTFE excels in this environment. It is resistant to virtually all disinfectants and sterilization agents that would degrade or destroy traditional rubber and elastomer seals over time. This ensures the seal maintains its integrity through repeated cleaning and sterilization cycles.

Unmatched Performance Under Stress

Beyond safety, a seal must perform its mechanical function reliably for the lifetime of the device. PTFE's physical properties ensure it can handle the operational demands of complex medical equipment.

Maintaining Integrity at Temperature and Pressure Extremes

From high-temperature autoclave cycles to the internal pressures of fluid pumps, medical seals face a wide range of conditions.

PTFE maintains its strength and structural form across a very broad temperature and pressure spectrum. Unlike many plastics that can soften or elastomers that can become brittle, PTFE remains stable and effective.

The Advantage of Low Friction

Many medical devices, such as pumps and fluid handling systems, have dynamic or moving parts that require sealing.

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. This means parts can move smoothly against the seal with minimal resistance or wear, improving efficiency and preventing the need for external lubricants that could contaminate the system.

Superior Durability and Lifespan

A failed seal can lead to device failure, contamination, or costly maintenance.

The combination of chemical resistance, wear resistance, and physical stability gives PTFE seals a dramatically longer service life compared to most alternatives. Furthermore, PTFE has an unlimited shelf life, as it does not degrade from exposure to moisture or UV rays.

Understanding the Trade-offs

While PTFE's advantages are significant, it's important to understand its specific mechanical nature to apply it correctly.

The Need for Spring-Energizing in Dynamic Seals

PTFE is a durable plastic, not a soft, bouncy rubber. It lacks the "memory" or elasticity of traditional elastomers.

In dynamic applications where the seal must constantly adapt to moving surfaces, a spring-energizer (often a metal spring) is embedded within the PTFE seal. This spring provides the constant, light pressure needed to maintain a tight seal where the PTFE material alone would not.

The Cost vs. Reliability Calculation

PTFE seals, particularly complex spring-energized designs, can have a higher initial cost than simple rubber O-rings.

However, this cost is almost always justified in critical medical applications. The investment prevents premature device failure, reduces long-term maintenance costs, and—most importantly—enhances the overall safety and reliability of the device.

Making the Right Choice for Your Application

Selecting the right seal material is a critical design decision. PTFE provides a solution for the most demanding medical scenarios.

- If your primary focus is patient safety and biocompatibility: PTFE's inertness and compliance with FDA and USP Class VI standards make it the default choice for fluid paths and patient-contact applications.

- If your primary focus is device reliability through repeated sterilization: PTFE's unmatched resistance to heat and aggressive chemicals ensures the seal will not degrade, providing long-term performance.

- If your primary focus is high-efficiency dynamic sealing: Spring-energized PTFE seals offer a low-friction, long-lasting solution for critical moving components like pumps, valves, and actuators.

Ultimately, choosing PTFE is an investment in the safety, reliability, and long-term performance of your medical device.

Summary Table:

| Key Property | Benefit for Medical Seals |

|---|---|

| Biocompatibility & Inertness | Non-toxic, FDA/USP Class VI compliant; safe for patient contact and pharmaceuticals. |

| Chemical & Thermal Resistance | Withstands aggressive sterilization (autoclaving, chemicals) without degradation. |

| Low Coefficient of Friction | Enables smooth operation in dynamic applications (e.g., pumps) without lubrication. |

| Durability & Longevity | Maintains integrity under extreme pressure and temperature, offering a longer service life. |

Ready to enhance the safety and reliability of your medical device with precision PTFE seals?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the medical, semiconductor, and laboratory industries. Our commitment to precision production and custom fabrication, from prototypes to high-volume orders, ensures you get the exact solution for your critical application.

Contact us today to discuss your project requirements and discover how our expertise can benefit your next design!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support