While prized for their low-friction properties, PTFE (Polytetrafluoroethylene) fork bushes introduce significant drawbacks stemming from their inherent softness. The material's tendency to embed contaminants can lead to abrasive wear on expensive fork stanchions, and its poor structural integrity can cause it to deform or "creep" under the high loads typical of suspension systems, compromising performance and safety.

The core issue with PTFE in this application is a fundamental trade-off: the very softness that provides low friction is also the source of its greatest vulnerabilities, namely its susceptibility to contamination damage and its inability to handle high dynamic loads without deforming.

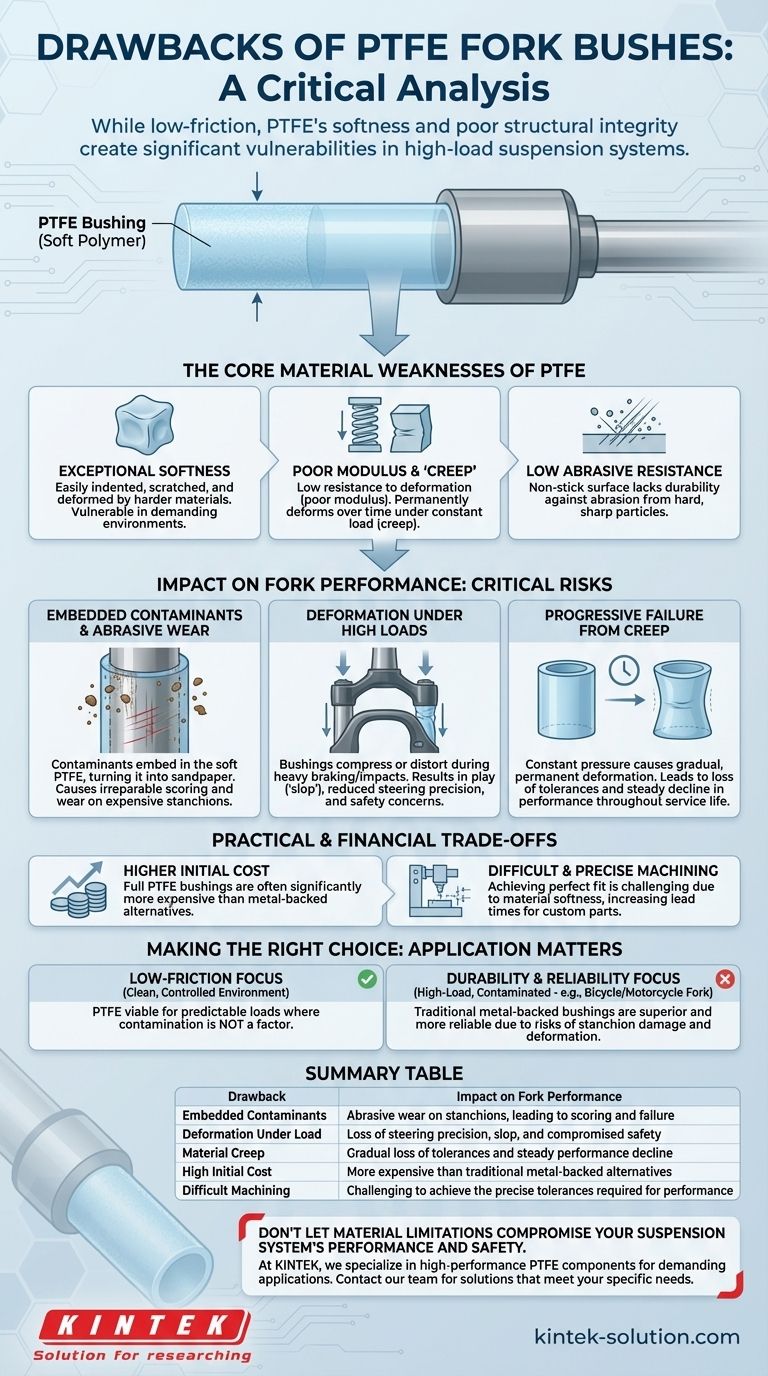

The Core Material Weaknesses of PTFE

To understand the risks, we must first look at the material's intrinsic properties. While excellent in some applications, these properties become liabilities within a suspension fork.

Exceptional Softness

PTFE is an incredibly soft polymer. This characteristic means it is easily indented, scratched, or deformed by harder materials. While this contributes to its low-friction feel, it makes it highly vulnerable in a mechanically demanding environment.

Poor Modulus and "Creep"

Modulus refers to a material's stiffness or resistance to being deformed elastically. PTFE has a poor modulus, meaning it flexes and gives way easily under load.

Furthermore, it exhibits creep, a tendency to slowly and permanently deform over time when subjected to a constant load. This means that even under static pressure, the bushing can gradually change shape, losing its precise dimensions.

Low Abrasive Resistance

The material's non-stick surface is not inherently durable against abrasion. Hard, sharp particles can easily cut into or embed themselves within the soft PTFE, a critical failure point we will explore next.

How These Weaknesses Impact Fork Performance

These material properties do not exist in a vacuum. Inside a suspension fork, they translate directly into tangible performance issues and potential damage.

The Critical Risk of Embedded Contaminants

Any dirt, grit, or metal particles that bypass the fork seals can become permanently embedded in the soft PTFE bushing.

Once embedded, these particles effectively turn the bushing into a strip of sandpaper. With every compression and rebound of the fork, this abrasive surface grinds against the hard-coated stanchion, causing scoring and irreparable wear. This is the single most catastrophic failure mode.

Deformation Under High Loads

During heavy braking, impacts, or hard cornering, a suspension fork is subjected to immense forces. The poor modulus of PTFE means the bushings can compress or distort under these loads.

This deformation creates play, or "slop," in the system. The result is a noticeable reduction in steering precision and a feeling of looseness in the front end of the vehicle.

Progressive Failure from Creep

The constant pressure from the fork stanchion can cause the PTFE bushing to creep over time. This slow deformation leads to a gradual loss of tolerances, increasing the play in the fork and diminishing performance steadily throughout its service life.

Understanding the Practical and Financial Trade-offs

Beyond the mechanical failures, there are practical considerations that make PTFE a challenging choice for this application.

Higher Initial Cost

Compared to traditional metal-backed, polymer-lined bushings, full PTFE bushings are often significantly more expensive to manufacture and purchase.

Difficult and Precise Machining

While PTFE is a soft material, machining it to the extremely tight tolerances required for a high-performance suspension fork is challenging. Its tendency to deform during the cutting process makes achieving a perfect fit and finish difficult, which can increase lead times for custom parts.

Making the Right Choice for Your Application

The decision to use PTFE bushings must be based on a clear understanding of the operating environment and performance priorities.

- If your primary focus is ultimate low-friction performance in a perfectly clean, controlled environment: PTFE can be a viable choice where loads are predictable and contamination is not a factor.

- If your primary focus is durability, reliability, and safety in a high-load, potentially contaminated environment (like a bicycle or motorcycle fork): The risks of stanchion damage and deformation often make traditional metal-backed bushings the superior and more reliable choice.

Ultimately, understanding these material limitations is crucial for ensuring both the performance and long-term safety of your suspension system.

Summary Table:

| Drawback | Impact on Fork Performance |

|---|---|

| Embedded Contaminants | Abrasive wear on stanchions, leading to scoring and failure |

| Deformation Under Load | Loss of steering precision, slop, and compromised safety |

| Material Creep | Gradual loss of tolerances and steady performance decline |

| High Initial Cost | More expensive than traditional metal-backed alternatives |

| Difficult Machining | Challenging to achieve the precise tolerances required for performance |

Don't let material limitations compromise your suspension system's performance and safety.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals, liners, and labware, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures that every component meets the exacting tolerances required for reliability and durability, from prototypes to high-volume orders.

If you're designing or maintaining a system that requires components with superior material properties and precise fabrication, contact our team today to discuss how we can provide a solution that meets your specific needs and avoids the common pitfalls of standard PTFE applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance