In the context of gaskets, "shrinkage performance" does not refer to the material shrinking but to its ductility and ability to undergo plastic deformation under a load. This property is what allows a Polytetrafluoroethylene (PTFE) gasket to conform precisely to flange surfaces, filling in microscopic imperfections to create a highly effective and reliable seal.

The essential function of a PTFE gasket's "shrinkage performance" is its capacity to deform and flow into the irregularities of mating surfaces. This conformability is the key mechanism that compensates for flange imperfections and prevents leakage.

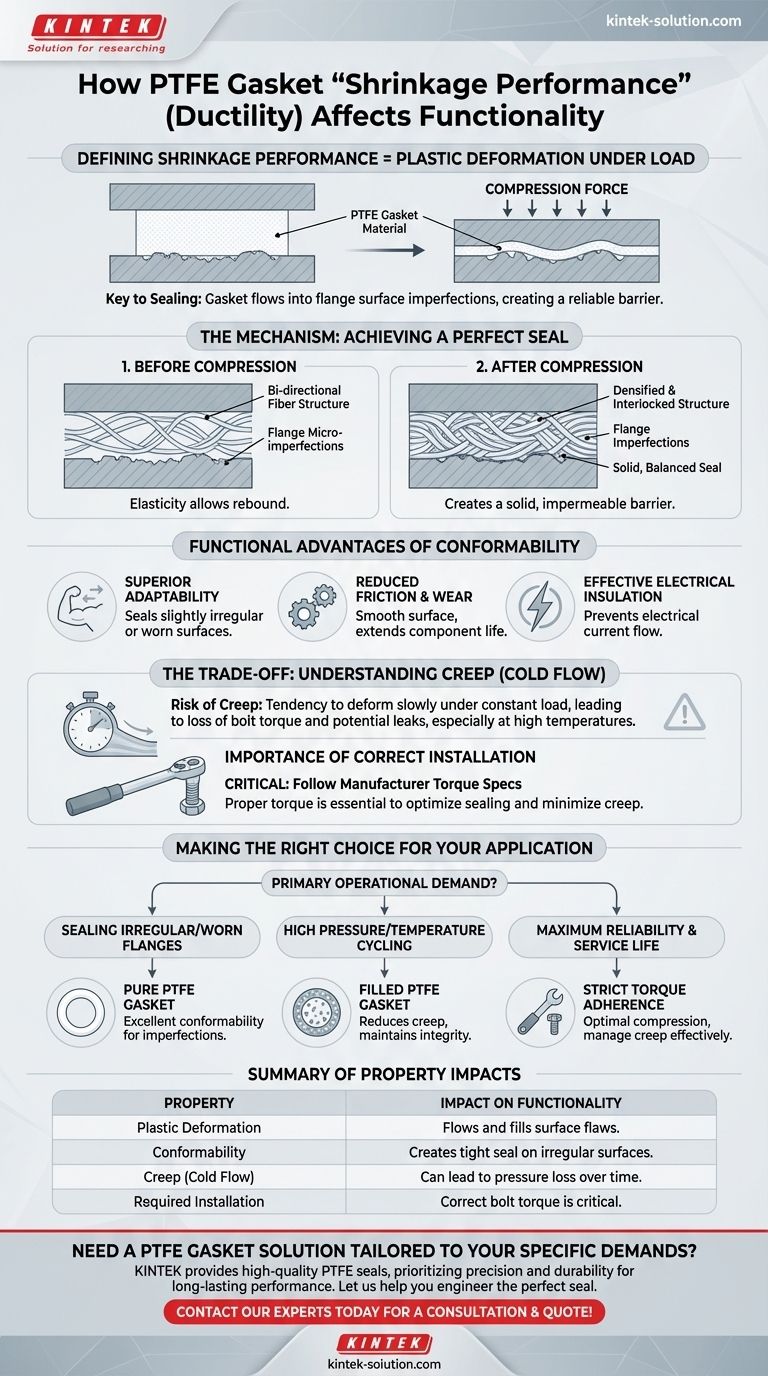

How PTFE Gaskets Achieve a Perfect Seal

A gasket's primary job is to create a static seal between two stationary components. The effectiveness of this seal depends entirely on the gasket's ability to adapt to the micro-topography of the flange faces it sits between.

The Role of Plastic Deformation

The term shrinkage performance is a technical way to describe the gasket's capacity for controlled plastic deformation. When you tighten the bolts on a flange, the gasket is compressed.

This compression causes the PTFE material to flow, or "shrink," into every scratch, pit, and wave on the flange surfaces. This action effectively transforms two imperfect metal surfaces into a single, continuous, and impermeable barrier.

From Fibers to a Solid Barrier

Many high-performance PTFE gaskets are constructed with a fine, bi-directional fiber structure. When uncompressed, this structure provides excellent elasticity, allowing the gasket to rebound.

When compressed, these fibers interlock and densify. This creates a solid, balanced structure that is exceptionally resistant to leaks while remaining flexible enough to compensate for minor surface flaws.

The Functional Advantages of PTFE's Conformability

This unique ability to deform and adapt provides several distinct operational benefits that make PTFE a preferred material in many demanding industrial applications.

Superior Adaptability

The inherent flexibility of PTFE allows it to create tight seals even on surfaces that are not perfectly flat or smooth. This adaptability makes PTFE gaskets suitable for a vast range of applications, from standard piping to complex equipment.

Reduced Friction and Wear

PTFE has an exceptionally low coefficient of friction. This results in a smooth surface that reduces wear on the sealing parts and the flanges themselves during installation and operation. This property helps extend the service life of both the gasket and the equipment.

Effective Electrical Insulation

In addition to its sealing properties, PTFE is an excellent electrical insulator. This makes PTFE gaskets invaluable in applications where it is necessary to isolate components electrically and prevent stray currents.

Understanding the Trade-offs

While the deformability of PTFE is its greatest strength, it is also the source of its primary limitation. Understanding this balance is critical for proper application.

The Risk of Creep (Cold Flow)

The same property that allows PTFE to conform so well can also lead to creep, also known as cold flow. This is the tendency of the material to continue deforming or "flowing" slowly over time while under a constant load.

Excessive creep can lead to a loss of bolt torque, which reduces the sealing pressure on the gasket and can eventually result in a leak. This is particularly relevant in applications with high temperatures or significant temperature cycling.

The Importance of Correct Installation

Because of PTFE's tendency to deform, proper installation and torque procedures are critical. Over-tightening a flange can crush the gasket, accelerating creep and causing premature failure. Following manufacturer specifications for bolt torque is essential to achieve a reliable, long-lasting seal.

Making the Right Choice for Your Application

Selecting the correct gasket and installation procedure depends entirely on the operational demands of the system.

- If your primary focus is sealing slightly irregular or worn flanges: The excellent conformability of pure PTFE makes it an ideal choice to compensate for surface imperfections.

- If your application involves high pressure or temperature cycling: Consider a filled PTFE gasket (e.g., glass-filled or carbon-filled) to reduce the risk of creep and maintain seal integrity.

- If your goal is maximum reliability and service life: Always adhere strictly to the specified bolt torque values and tightening patterns to achieve the optimal compression without inducing excessive creep.

Ultimately, understanding a material's capacity for deformation is the key to engineering a dependable and long-lasting seal.

Summary Table:

| Property | Impact on Gasket Functionality |

|---|---|

| Plastic Deformation | Allows gasket to flow and fill microscopic surface flaws on flanges. |

| Conformability | Creates a tight, reliable seal even on irregular or worn surfaces. |

| Creep (Cold Flow) | A trade-off; can lead to loss of sealing pressure over time if not managed. |

| Required Installation | Correct bolt torque is critical to optimize performance and minimize creep. |

Need a PTFE Gasket Solution Tailored to Your Specific Demands?

At KINTEK, we understand that the precise performance of a PTFE gasket is critical to your operation's safety and efficiency. Whether you're sealing flanges in the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures you get the right component.

We manufacture high-quality PTFE seals, liners, and labware, prioritizing precision and durability. From custom prototypes to high-volume orders, we provide solutions that effectively manage deformation and creep for long-lasting, reliable seals.

Let us help you engineer the perfect seal. Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials