In industrial settings, the lightweight nature of PTFE bushes reduces the overall mass and inertia of moving assemblies, while their durability ensures consistent, long-lasting performance even under high-load, high-speed, and chemically aggressive conditions. This unique combination directly translates to improved equipment efficiency, reduced energy consumption, and lower long-term maintenance costs.

The true benefit of PTFE is not just that it's light and durable, but how these properties work in concert with its other elite characteristics—low friction, chemical inertness, and temperature resistance—to solve complex engineering challenges where traditional materials would quickly fail.

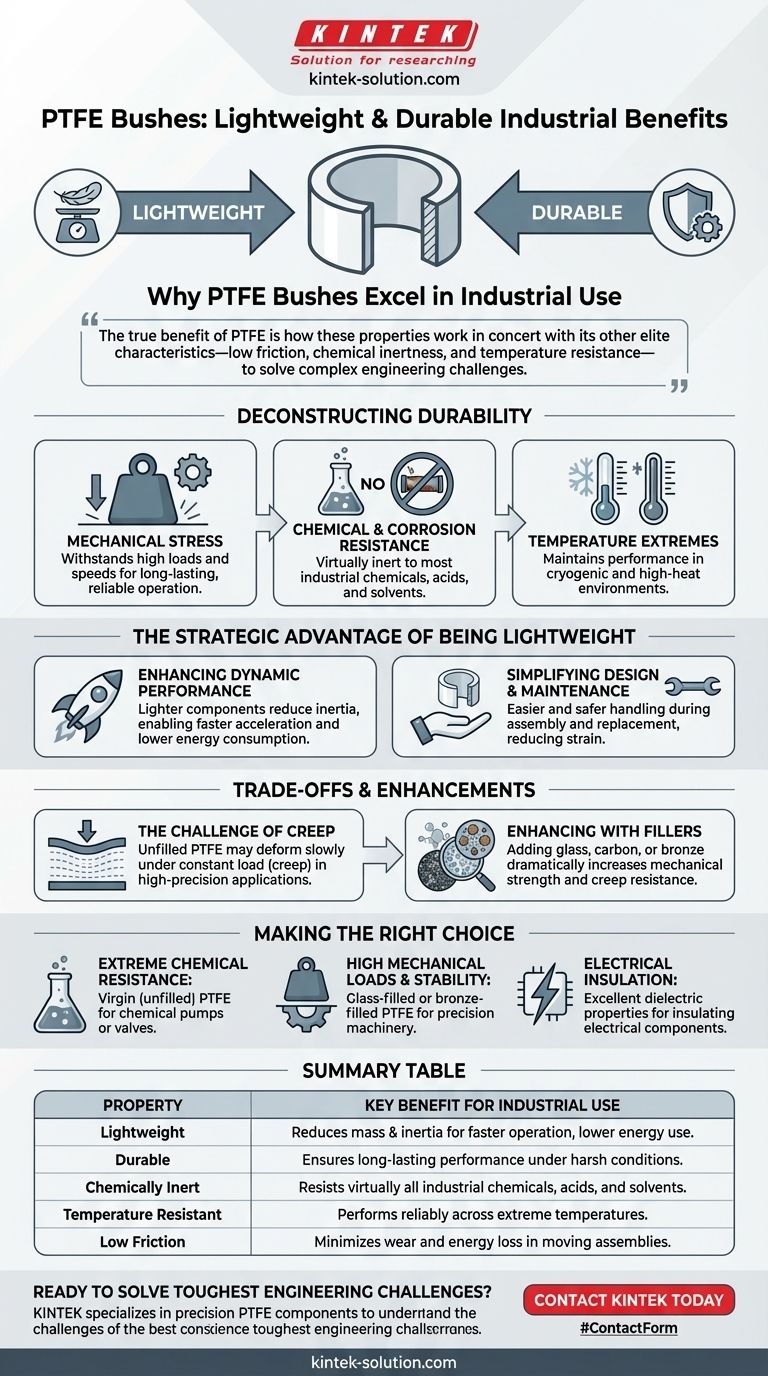

Deconstructing "Durability" in Industrial Contexts

The term "durability" for a PTFE bush goes far beyond simple wear resistance. It encompasses resilience against the three primary stressors in most industrial environments: mechanical load, chemical attack, and temperature extremes.

Resilience Under Mechanical Stress

PTFE bushes excel in high-load and high-speed applications. Their ability to withstand continuous mechanical stress without significant degradation ensures predictable and reliable machinery operation over long periods.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it the ideal choice for bushings used in chemical processing, pharmaceuticals, and environments where corrosion would destroy metal or other polymer components.

Stability Across Extreme Temperatures

With a high melting point and the ability to perform reliably across a wide temperature range, PTFE maintains its structural integrity and performance properties in both cryogenic applications and high-heat environments.

The Strategic Advantage of Being Lightweight

While durability ensures longevity, the low density of PTFE provides a distinct performance advantage, particularly in applications where mass is a critical design factor.

Enhancing Dynamic Performance

In high-speed machinery, robotics, or aerospace applications, every gram matters. Lighter components reduce inertia, allowing for faster acceleration, quicker directional changes, and lower overall energy consumption.

Simplifying Design and Maintenance

Lightweight bushes are easier and safer to handle during assembly and replacement. This can simplify the design of supporting structures and reduce the physical strain on maintenance personnel.

Understanding the Trade-offs and Enhancements

Objectively assessing any material requires understanding its limitations. While exceptionally capable, standard PTFE is not a universal solution for every high-load scenario.

The Challenge of Creep in Unfilled PTFE

Standard, or "virgin," PTFE can be susceptible to creep—a slow deformation that occurs over time when under a constant load. In high-precision applications with sustained high pressure, this can eventually compromise dimensional tolerances.

How Fillers Radically Enhance Durability

To overcome this limitation, PTFE is often compounded with reinforcing fillers. These additives create a composite material with vastly superior mechanical properties.

Common fillers like glass, carbon, or bronze dramatically increase mechanical strength, improve creep resistance, and enhance dimensional stability, making the bushes suitable for the most demanding industrial loads without sacrificing PTFE's core benefits.

Making the Right Choice for Your Application

Selecting the correct PTFE formulation is critical to maximizing performance and lifespan. Your primary operational goal should guide your decision.

- If your primary focus is extreme chemical resistance: Virgin (unfilled) PTFE provides the highest level of chemical inertness for applications like chemical processing pumps or valves.

- If your primary focus is high mechanical loads and stability: A glass-filled or bronze-filled PTFE bush offers superior strength and creep resistance for precision machinery and high-pressure systems.

- If your primary focus is electrical insulation: PTFE's excellent dielectric properties make it the default choice for insulating components in electrical equipment, preventing arcing and ensuring safety.

By understanding this balance of properties, you can select a material that delivers exceptional performance and reliability for your specific challenge.

Summary Table:

| Property | Key Benefit for Industrial Use |

|---|---|

| Lightweight | Reduces mass and inertia for faster operation and lower energy consumption. |

| Durable | Ensures long-lasting performance under high load, speed, and harsh conditions. |

| Chemically Inert | Resists virtually all industrial chemicals, acids, and solvents. |

| Temperature Resistant | Performs reliably across a wide range of extreme temperatures. |

| Low Friction | Minimizes wear and energy loss in moving assemblies. |

Ready to solve your toughest engineering challenges with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE bushes, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need extreme chemical resistance, superior mechanical strength with filled compounds, or custom fabrication from prototypes to high-volume orders, our expertise ensures a solution that enhances your equipment's efficiency and reliability.

Contact KINTEK today to discuss your specific application and receive a custom quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments