In the oil and gas industry, the most chemically aggressive media commonly encountered are sour gas and acid gas. Polytetrafluoroethylene (PTFE) seals are exceptionally effective in these environments due to their inherent chemical inertness, which allows them to resist degradation and maintain a secure seal even when combined with the extreme pressures and temperatures typical of these applications.

PTFE's fundamental chemical resistance makes it the material of choice for sealing in corrosive oil and gas environments. Its effectiveness is further enhanced through engineering, such as spring energizing, which compensates for the material's natural limitations under extreme operational stress.

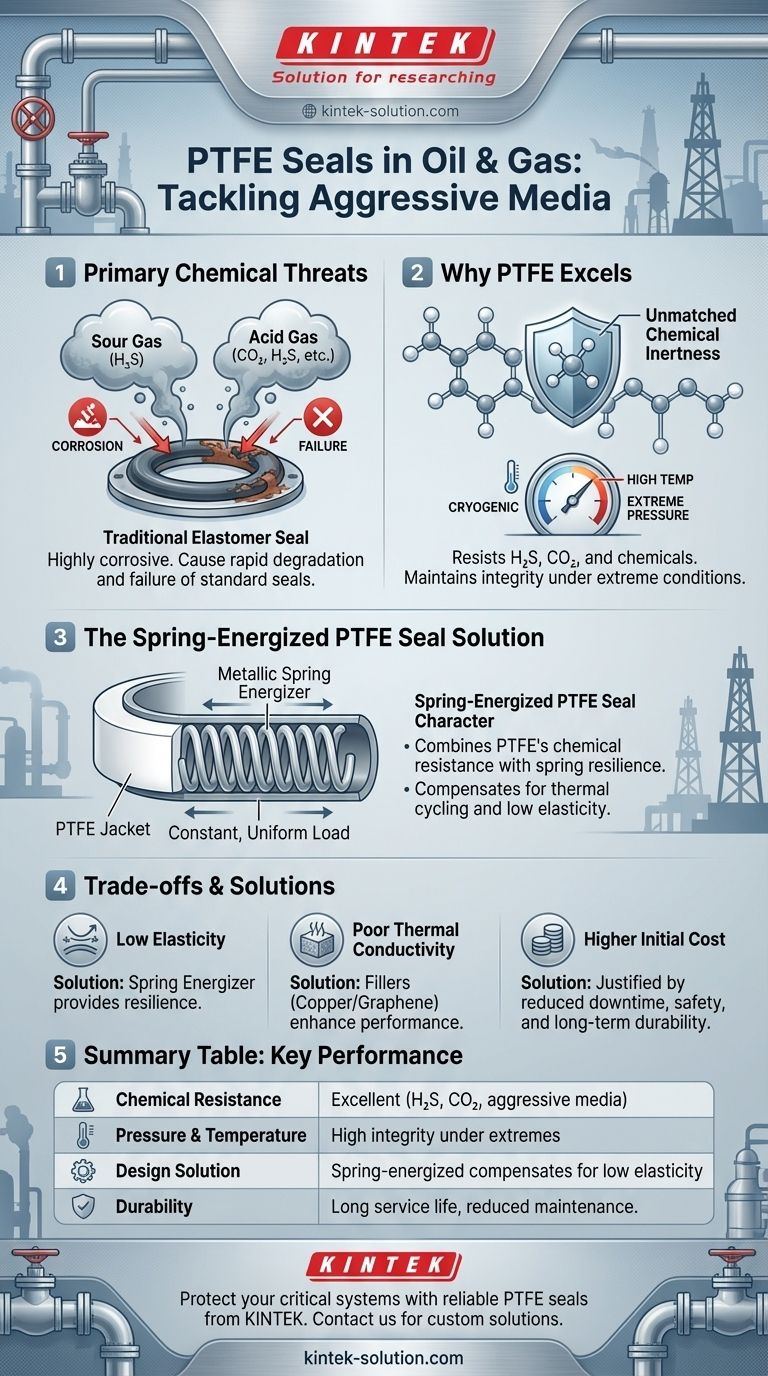

The Primary Chemical Threats in Oil & Gas

Defining Sour and Acid Gas

Sour gas is natural gas containing significant amounts of hydrogen sulfide (H₂S). Acid gas is a broader term that can include H₂S, carbon dioxide (CO₂), and other acidic components.

These compounds are highly corrosive, especially in the presence of water, and pose a severe threat to the integrity of equipment.

The Impact on Standard Sealing Materials

When exposed to sour and acid gases, conventional elastomers and metal components can degrade rapidly. This chemical attack leads to seal failure, leaks, and potentially catastrophic equipment damage, posing significant safety and environmental risks.

Why PTFE Excels in Aggressive Environments

Unmatched Chemical Inertness

PTFE is a fluoropolymer with an extremely strong carbon-fluorine bond, making it one ofthe most chemically resistant materials available. It does not react with sour gas, acid gas, or the vast majority of industrial chemicals, ensuring the seal material itself does not become a point of failure.

Performance Under Pressure and Temperature

The challenging conditions of oil and gas operations involve more than just chemical exposure. PTFE seals are engineered to maintain their integrity and sealing force across a wide range of high pressures and extreme temperatures, from cryogenic to several hundred degrees.

The Role of the Spring Energizer

A key design innovation is the spring-energized PTFE seal. This combines a PTFE jacket with a metallic spring energizer.

The spring provides a constant, uniform load on the seal lips. This force compensates for PTFE's naturally low elasticity, ensuring the seal maintains intimate contact with the hardware and retains its shape despite thermal cycling, high pressure, and chemical exposure.

Understanding the Trade-offs of PTFE

Low Elasticity

By itself, PTFE has poor "memory" and does not readily return to its original shape after being compressed. This limitation is directly and effectively solved by incorporating a spring energizer, which provides the necessary resilience for a dynamic and reliable seal.

Poor Thermal Conductivity

Standard PTFE is not a good conductor of heat, which can be a concern in some high-speed applications. However, this is often improved by adding fillers such as copper or graphene to the PTFE blend, enhancing thermal performance.

Higher Initial Cost

PTFE seals, particularly advanced spring-energized designs, can have a higher upfront cost than traditional elastomeric seals. This cost is justified in critical applications where the price of failure—in terms of downtime, safety incidents, and equipment replacement—is vastly higher. Their exceptional durability reduces the need for frequent maintenance and replacement.

Making the Right Choice for Your Application

Choosing the correct seal requires balancing performance requirements with operational realities.

- If your primary focus is maximum uptime in critical sour gas service: A spring-energized PTFE seal is the definitive choice for its unmatched chemical resistance and reliability under extreme conditions.

- If your primary focus is long-term equipment protection: The durability of PTFE protects not just the seal but also the surrounding hardware from corrosive wear, extending the lifespan of valuable assets like valves.

- If your primary focus is optimizing cost-effectiveness: Deploy PTFE seals strategically in the most critical applications where chemical attack is most severe and seal failure is not an option.

Ultimately, specifying the right sealing material is a foundational step in ensuring the safety, reliability, and longevity of your critical systems.

Summary Table:

| Key Characteristic | PTFE Seal Performance |

|---|---|

| Chemical Resistance | Excellent resistance to H₂S, CO₂, and most aggressive media. |

| Pressure & Temperature | Maintains integrity under high pressure and extreme temperatures. |

| Design Solution | Spring-energized design compensates for low elasticity. |

| Durability | Long service life reduces maintenance and downtime. |

Protect your critical oil and gas systems with reliable, high-performance PTFE seals from KINTEK.

We specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication ensures your equipment operates safely and efficiently in the most aggressive environments.

Contact us today to discuss your specific sealing challenges and discover how KINTEK solutions can enhance your operational reliability.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C