At its core, PTFE (Polytetrafluoroethylene) is considered the best material for heavy-duty cable liners because it possesses a unique combination of properties that metals cannot match. Unlike steel, PTFE offers an extremely low coefficient of friction, high abrasion resistance, and near-total chemical inertness, which translates directly to longer system life, lower energy consumption, and superior reliability in demanding environments.

The choice between PTFE and metal is not a simple substitution. Opting for a PTFE liner is a fundamental engineering upgrade that enhances the performance and longevity of the entire cable system by actively reducing the primary forces of failure: friction and corrosion.

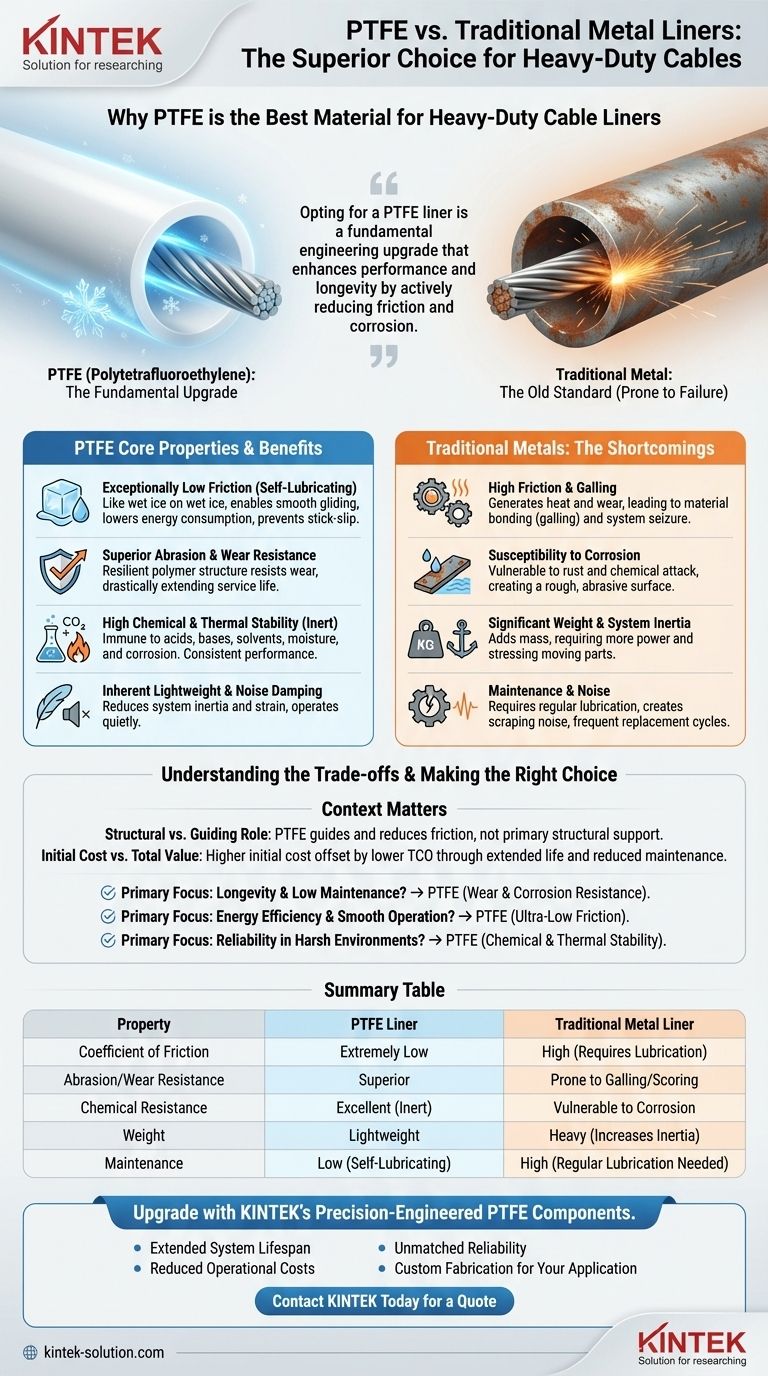

The Core Properties of PTFE Liners

To understand why PTFE excels, we must look at its fundamental material characteristics and how they directly benefit a heavy-duty cable system.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice.

This self-lubricating property means the cable glides through the liner with minimal resistance. This reduces the force needed to move the cable, lowers energy consumption, and prevents the stick-slip motion that can damage sensitive internal wires.

Superior Abrasion and Wear Resistance

In a heavy-duty application, the cable is in constant motion, creating a high-wear environment.

PTFE's polymer structure is exceptionally resilient to this type of abrasive wear. It resists being worn away by the moving cable, drastically extending the service life of the liner and the cable itself compared to a metal liner which can score or gall over time.

High Chemical and Thermal Stability

PTFE is renowned for its chemical inertness, stemming from its strong carbon-fluorine bonds.

This makes it virtually immune to acids, bases, solvents, and moisture that would cause a traditional steel liner to corrode. This resistance ensures that friction remains low and consistent throughout the liner's life, even in harsh industrial or outdoor settings.

Inherent Lightweight and Noise Damping

As a polymer, PTFE is significantly lighter than steel.

This reduces the overall weight and inertia of the cable management system, putting less strain on drive components. Additionally, it naturally dampens the sound of the moving cable, creating quieter operation compared to the scraping noise of metal-on-metal contact.

Why Traditional Metals Fall Short

Understanding PTFE's advantages is clearer when directly compared to the limitations of traditional metal-based liners in the same application.

The Problem of Friction and Galling

Even when lubricated, metal-on-metal contact generates significant friction.

Over time, this can lead to galling—a severe form of wear where material is pulled from one surface and bonds to the other. This creates high-friction spots that can abrade the cable jacket and eventually cause the system to seize.

Susceptibility to Corrosion

Steel liners are vulnerable to rust and chemical attack.

Corrosion creates a rough, abrasive surface that dramatically increases friction and accelerates the destruction of the cable jacket. This requires more frequent maintenance and replacement cycles.

Weight and System Inertia

The sheer weight of steel liners adds significant mass to the system.

This increased inertia requires more powerful motors and puts greater stress on all moving parts, from the drive system to the support structure, leading to higher energy use and potential for premature failure.

Understanding the Trade-offs

No material choice is without context. While PTFE is superior for this application, it's important to understand its relative limitations to make a fully informed decision.

Structural vs. Guiding Role

PTFE has a lower compressive strength and rigidity than steel.

It is crucial to recognize that the liner's function is to guide the cable and reduce friction, not to provide the primary structural support. That role belongs to the surrounding cable carrier or conduit. PTFE is engineered for its surface properties, not its structural load-bearing capacity.

Initial Material Cost

The initial procurement cost of PTFE components can be higher than that of simple steel parts.

However, this initial expense is frequently offset by a lower total cost of ownership. The extended lifespan, elimination of external lubrication, and reduced maintenance downtime often make PTFE the more economical choice over the system's life.

Making the Right Choice for Your Application

Your final decision should be guided by the primary performance goal of your system.

- If your primary focus is longevity and low maintenance: PTFE is the definitive choice due to its inherent wear resistance and immunity to corrosion.

- If your primary focus is energy efficiency and smooth operation: PTFE's ultra-low friction reduces power requirements and eliminates the stick-slip effect common in metal systems.

- If your primary focus is reliability in harsh environments: PTFE's chemical and thermal stability ensures consistent performance where metals would quickly degrade.

Ultimately, choosing PTFE is an investment in the long-term performance and reliability of your entire mechanical system.

Summary Table:

| Property | PTFE Liner | Traditional Metal Liner |

|---|---|---|

| Coefficient of Friction | Extremely Low | High (Requires Lubrication) |

| Abrasion/Wear Resistance | Superior | Prone to Galling/Scoring |

| Chemical Resistance | Excellent (Inert) | Vulnerable to Corrosion |

| Weight | Lightweight | Heavy (Increases Inertia) |

| Maintenance | Low (Self-Lubricating) | High (Regular Lubrication Needed) |

Upgrade your cable management system with KINTEK's precision-engineered PTFE components.

Our custom-fabricated PTFE liners, seals, and labware are designed for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. By choosing KINTEK, you benefit from:

- Extended System Lifespan: Superior abrasion resistance reduces wear on both the liner and cable.

- Reduced Operational Costs: Ultra-low friction lowers energy consumption and eliminates the need for external lubricants.

- Unmatched Reliability: Chemical inertness ensures consistent performance in harsh conditions, preventing unexpected downtime.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your application.

Contact KINTEK today to discuss your specific requirements and receive a quote for a PTFE solution that enhances your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials