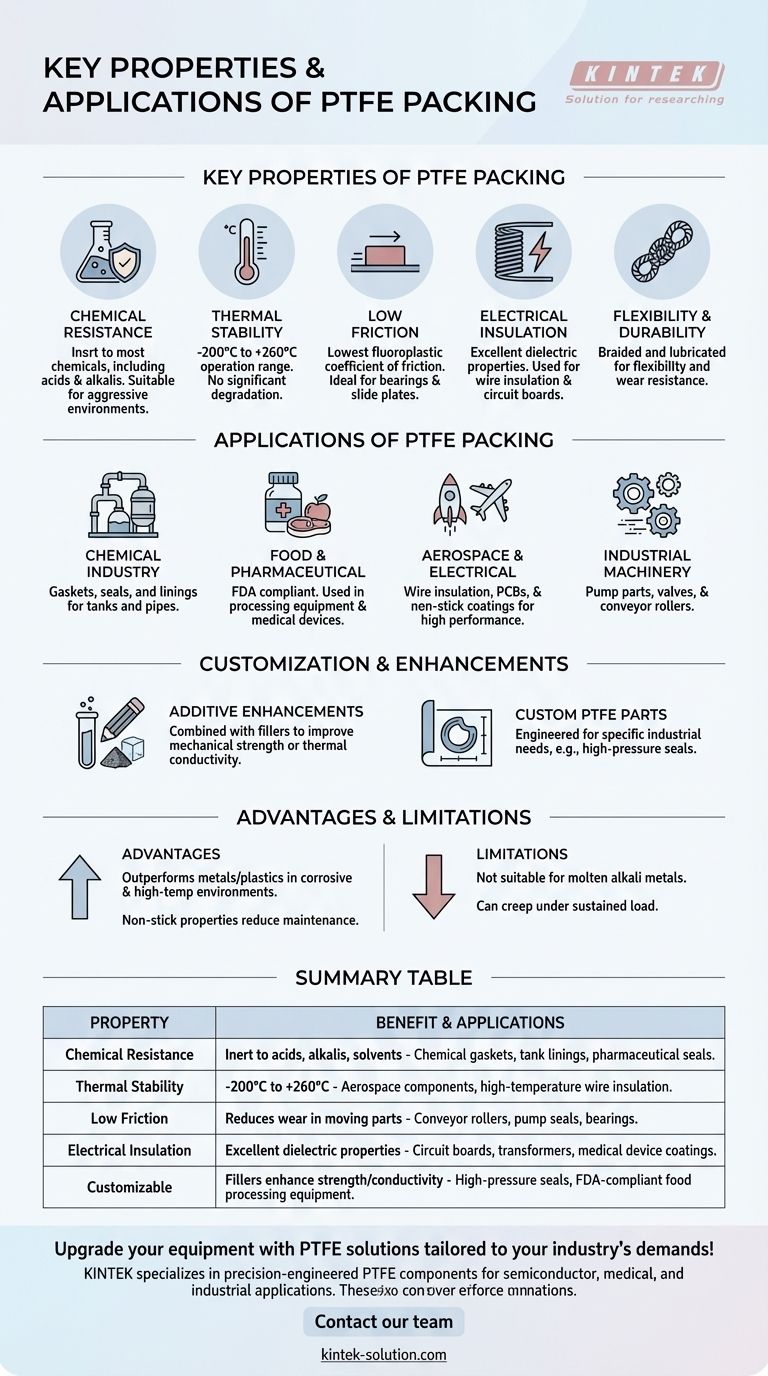

PTFE packing is a versatile synthetic polymer known for its exceptional chemical resistance, thermal stability, and low friction properties. It is widely used in industries such as chemical processing, pharmaceuticals, food production, aerospace, and electrical applications due to its ability to withstand harsh environments, including exposure to aggressive chemicals, high temperatures, and mechanical wear. PTFE packing is also valued for its electrical insulation properties and can be customized with additives to meet specific requirements, such as FDA compliance for food and pharmaceutical applications. Its flexibility and durability make it ideal for sealing, insulation, and non-stick applications.

Key Points Explained:

-

Key Properties of PTFE Packing

- Chemical Resistance: PTFE is inert to most chemicals, including acids, alkalis, and solvents, making it suitable for aggressive environments.

- Thermal Stability: It can operate in temperatures ranging from -200°C to +260°C without significant degradation.

- Low Friction: PTFE has the lowest coefficient of friction among fluoroplastics, ideal for bearings, slide plates, and conveyor systems.

- Electrical Insulation: Its dielectric properties make it useful for wire insulation, circuit boards, and transformers.

- Flexibility and Durability: PTFE packing is braided and lubricated for flexibility, providing excellent wear resistance on shafts and seals.

-

Applications of PTFE Packing

- Chemical Industry: Used in gaskets, seals, and linings for tanks and pipes due to its chemical inertness.

- Food and Pharmaceutical: Compliant with FDA standards, PTFE is used in food processing equipment, medical devices (e.g., catheters, syringes), and packaging.

- Aerospace and Electrical: Employed in wire insulation, PCBs, and non-stick coatings for high-performance applications.

- Industrial Machinery: Ideal for pump parts, valves, and conveyor rollers where low friction and durability are critical.

-

Customization and Enhancements

- PTFE can be combined with fillers like graphite or glass to improve mechanical strength or thermal conductivity.

- Custom PTFE parts can be engineered for specific industrial needs, such as high-pressure seals or specialized coatings.

-

Advantages Over Other Materials

- Outperforms metals and other plastics in corrosive or high-temperature environments.

- Non-stick properties reduce maintenance and improve efficiency in food and chemical processing.

-

Limitations

- Not suitable for molten alkali metals.

- Can creep under sustained load, requiring design adjustments in mechanical applications.

PTFE packing’s unique combination of properties ensures its widespread use across industries, offering reliability and longevity in demanding conditions.

Summary Table:

| Property | Benefit | Applications |

|---|---|---|

| Chemical Resistance | Inert to acids, alkalis, solvents | Chemical gaskets, tank linings, pharmaceutical seals |

| Thermal Stability | Operates from -200°C to +260°C | Aerospace components, high-temperature wire insulation |

| Low Friction | Reduces wear in moving parts | Conveyor rollers, pump seals, bearings |

| Electrical Insulation | Excellent dielectric properties | Circuit boards, transformers, medical device coatings |

| Customizable | Fillers (e.g., graphite) enhance strength/conductivity | High-pressure seals, FDA-compliant food processing equipment |

Upgrade your equipment with PTFE solutions tailored to your industry’s demands!

KINTEK specializes in precision-engineered PTFE components—from seals and liners to custom labware—designed for semiconductor, medical, and industrial applications. Our expertise ensures durability, compliance, and performance in extreme conditions.

Contact our team to discuss custom PTFE fabrication or browse our high-performance solutions today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What causes a PTFE butterfly valve to leak? Diagnose and Prevent Seal Failure

- What is PTFE and why is it used in sealing applications? Unlock Superior Chemical & Temperature Resistance

- What chemical resistance properties does PTFE bellow seal possess? Unmatched Protection Against Corrosive Media

- What are the main advantages of expanded PTFE gaskets? Superior Sealing Reliability vs. Pure PTFE

- What are the primary applications of PTFE ring gaskets? Solve Your Toughest Sealing Challenges

- What are the key advantages of PTFE-jacketed spring energized seals? Unlock Unmatched Sealing Performance

- What industries are PTFE gaskets particularly suitable for? Ideal for Chemical, Pharma, and Food Processing

- How are PTFE gaskets used in the petroleum and chemical industry? Ensure Leak-Proof Sealing in Harsh Environments