At its core, a Polytetrafluoroethylene (PTFE) bellow seal possesses arguably the broadest chemical resistance of any known plastic. It is virtually inert when exposed to the vast majority of industrial chemicals, including concentrated acids, bases, solvents, and oxidizing agents, even at elevated temperatures. Its reliability stems from being unaffected by nearly all corrosive liquids, vapors, and gases.

The exceptional chemical resistance of PTFE is a direct result of its molecular structure, specifically the powerful carbon-fluorine bonds. While this makes it a default choice for aggressive media, you must be aware of its few critical vulnerabilities: molten alkali metals and certain fluorine compounds at high temperatures and pressures.

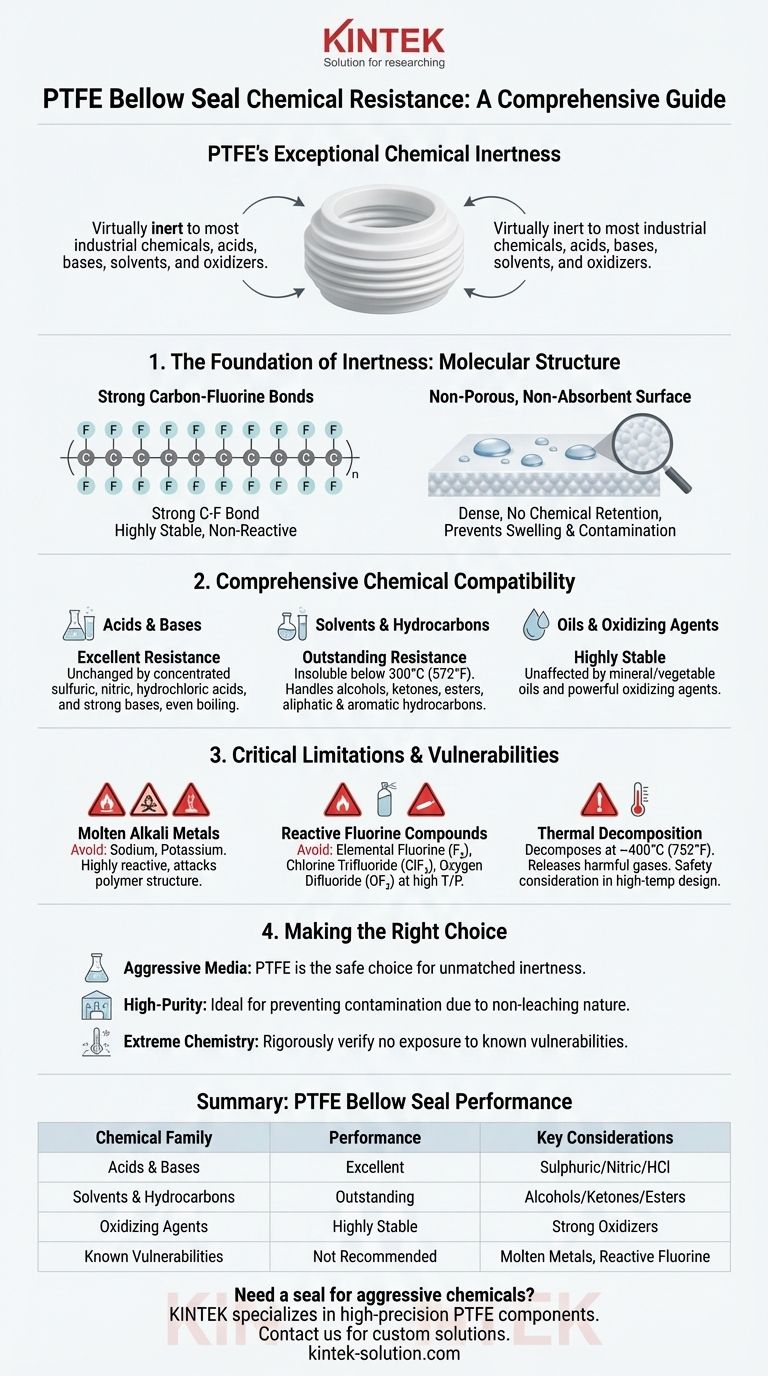

The Foundation of PTFE's Chemical Inertness

To understand the performance of a PTFE seal, we must first look at its unique molecular properties. Its resilience is not a surface treatment but an intrinsic characteristic of the material itself.

The Strength of Carbon-Fluorine Bonds

The PTFE molecule is composed of a long chain of carbon atoms, each completely shielded by fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest known in organic chemistry.

This extreme bond strength makes the molecule highly stable and non-reactive. It lacks an easy pathway for chemical attack, rendering it inert to substances that would readily degrade other polymers.

A Non-Porous, Non-Absorbent Surface

PTFE is a dense material with a non-porous and non-absorbent surface. This prevents chemicals from soaking into the seal material, which is critical for two reasons.

First, it stops the seal from swelling, softening, or degrading from within. Second, it minimizes the risk of cross-contamination between different process batches, as there is virtually no chemical retention.

Comprehensive Chemical Compatibility

The practical result of PTFE's molecular structure is its outstanding performance across an extremely wide range of chemical families.

Resistance to Aggressive Acids and Bases

PTFE remains completely unchanged when exposed to highly corrosive acids. This includes concentrated sulfuric, nitric, and hydrochloric acids, even while boiling. It is equally resistant to strong bases.

Stability in Solvents and Hydrocarbons

PTFE is notable for its insolubility in all known solvents below 300°C (572°F). It shows excellent resistance to alcohols, ketones, esters, and both aliphatic and aromatic hydrocarbons.

Performance with Oils and Oxidizing Agents

The material is also unaffected by mineral oils, vegetable oils, and a wide range of powerful oxidizing agents. This makes it suitable for a diverse set of industrial processes.

Understanding the Critical Limitations

No material is universally perfect. While PTFE's list of incompatibilities is remarkably short, ignoring them can lead to catastrophic seal failure. These exceptions typically involve extreme chemical and thermal conditions.

Vulnerability to Molten Alkali Metals

The most cited exception is molten alkali metals, such as sodium and potassium. These highly reactive elements are capable of attacking the PTFE polymer structure.

Reactions with Elemental Fluorine and Halogenated Compounds

While PTFE is a fluoropolymer, it can be attacked by other highly reactive fluorine compounds. This includes elemental fluorine (F₂), chlorine trifluoride (ClF₃), and oxygen difluoride (OF₂), particularly at high temperatures and pressures.

Thermal Decomposition

PTFE is thermally stable over a wide operating temperature range, but it is not infinite. The material begins to decompose at approximately 400°C (752°F), at which point it can release harmful gases. This is a critical safety consideration in high-temperature system design.

Making the Right Choice for Your Application

Selecting a seal material requires matching its capabilities to the specific demands of your process environment.

- If your primary focus is handling aggressive acids, bases, and solvents: PTFE is an almost universally safe and reliable choice, providing unmatched inertness where other materials would quickly fail.

- If your primary focus is high-purity applications: The non-absorbent, non-leaching nature of PTFE makes it an ideal choice for preventing process contamination.

- If your primary focus is extreme, reactive chemistry: You must rigorously verify that your process does not involve PTFE's few known vulnerabilities, namely molten alkali metals or specific reactive fluorine compounds.

Understanding both the exceptional strengths and the precise limitations of PTFE empowers you to deploy it with confidence.

Summary Table:

| Chemical Family | PTFE Bellow Seal Performance | Key Considerations |

|---|---|---|

| Acids & Bases | Excellent resistance, even at high concentrations and temperatures. | Ideal for sulfuric, nitric, and hydrochloric acids. |

| Solvents & Hydrocarbons | Outstanding resistance; insoluble below 300°C (572°F). | Handles alcohols, ketones, esters, and aromatics. |

| Oxidizing Agents | Highly stable and unaffected. | Suitable for processes with strong oxidizers. |

| Known Vulnerabilities | Not Recommended for these specific conditions. | Avoid molten alkali metals and certain fluorine compounds at high T/P. |

Need a seal that can handle your most aggressive chemicals?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including bellow seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment is protected against corrosive media, preventing downtime and contamination.

We offer custom fabrication from prototypes to high-volume orders, tailoring the solution to your exact application requirements.

Contact KINTEK today to discuss your specific chemical resistance needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the difference between a ball valve seat and an O-ring? Master Valve Sealing for Reliable Performance

- What material properties make polymer-plastic ball bearings suitable for diverse industries? Solve Harsh Environment Challenges

- How do PTFE slide bearings compare to traditional expansion plates? Superior Performance & Lower Lifetime Cost

- What are the key properties of PTFE guide strips? Ensure Low-Friction, High-Temp Performance

- How are PTFE tubes manufactured and what are their uses? A Guide to High-Performance Tubing Solutions

- How are PTFE bushes manufactured to ensure quality? A Guide to Precision and Reliability

- How are ePTFE sheets utilized in the automotive industry? Achieve Unmatched Reliability in Harsh Environments

- How do PTFE lined check valves differ from traditional swing check valves? A Guide to Superior Flow Control