In short, the key advantages are exceptional performance under extreme conditions. PTFE-jacketed spring energized seals offer universal chemical resistance, a vast operating temperature range from cryogenic to high heat, and superior high-pressure capabilities. This is combined with extremely low friction, making them ideal for applications where conventional elastomeric seals would quickly fail.

The fundamental advantage is not just the material properties of PTFE, but the synergy between the resilient jacket and the internal spring. This combination provides a constant, reliable sealing force that actively compensates for wear, pressure fluctuations, and thermal expansion where other seals would permanently deform and leak.

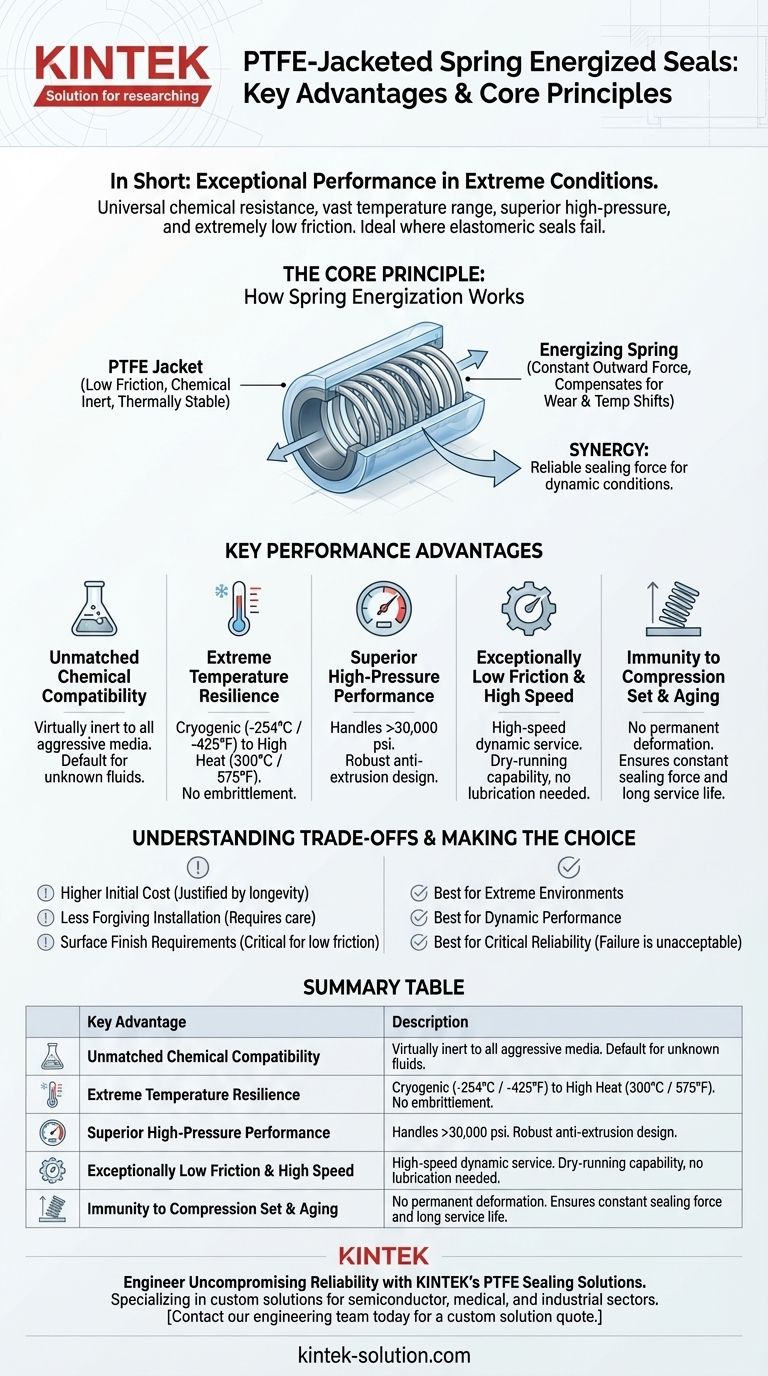

The Core Principle: How Spring Energization Works

To understand the advantages, it's critical to understand the design. These seals are not monolithic; they are a two-part system designed for resilience.

The Role of the PTFE Jacket

The outer jacket is made from Polytetrafluoroethylene (PTFE) or a similar high-performance polymer. This material is selected for its inherent properties.

It provides low friction, chemical inertness, and thermal stability. Unlike a rubber O-ring, the PTFE jacket itself has very little elastic memory.

The Function of the Energizing Spring

The internal spring is the engine of the seal. It exerts a constant outward force, pressing the PTFE jacket lips firmly against the sealing surfaces.

This spring action ensures a tight seal even at low pressures and compensates for dimensional changes caused by temperature shifts, material creep, or jacket wear over time.

Key Performance Advantages in Demanding Environments

The combination of the jacket and spring creates a sealing solution that excels where others cannot.

Unmatched Chemical Compatibility

The PTFE jacket is virtually inert to all industrial chemicals and fluids. This makes it the default choice for aggressive media or applications where fluid compatibility is unknown or variable.

Extreme Temperature Resilience

These seals perform reliably across an exceptionally wide temperature range. They maintain integrity in cryogenic services (down to -425°F / -254°C) and in high-temperature applications (up to 575°F / 300°C) where elastomers would become brittle or degrade.

Superior High-Pressure Performance

The robust design, often incorporating anti-extrusion features, allows these seals to handle extreme pressures, with some designs rated for over 30,000 psi. They resist extrusion far better than standard O-rings.

Exceptionally Low Friction and High Speed

PTFE has one of the lowest coefficients of friction of any solid material. This allows for high-speed dynamic service and even dry-running capabilities without requiring lubrication, reducing system complexity and contamination risk.

Immunity to Compression Set and Aging

Elastomeric seals can permanently deform under prolonged compression, a failure mode known as compression set. PTFE seals are immune to this. The spring ensures they always return to their intended shape, providing unparalleled service life and reliability, as they do not suffer from age-related embrittlement.

Understanding the Trade-offs

While powerful, these seals are a specialized solution, and it's important to understand their specific considerations.

Higher Initial Cost

The advanced materials and multi-component manufacturing process make spring energized seals significantly more expensive than commodity elastomeric seals. Their cost is justified by performance and longevity in applications where other seals would result in costly failure and downtime.

Less Forgiving Installation

PTFE is a relatively rigid polymer compared to rubber. The seal jacket can be damaged or scratched during installation if proper care and tools are not used. A compromised jacket surface can create a leak path.

Surface Finish Requirements

To leverage the low-friction benefit and ensure a long life, the mating hardware surfaces must be finished to a high standard. A rougher surface can cause premature wear on the PTFE jacket.

Making the Right Choice for Your Application

Use this guide to determine if a PTFE-jacketed spring energized seal is the correct solution for your engineering challenge.

- If your primary focus is extreme environments: This is the ideal choice for applications involving corrosive chemicals, cryogenic temperatures, or very high heat where elastomers cannot survive.

- If your primary focus is dynamic performance: Choose this seal for high-speed rotating or reciprocating motion, especially in applications where low friction is critical or lubrication is not possible.

- If your primary focus is reliability and longevity: This seal is the solution for critical hardware where seal failure is unacceptable and immunity to compression set is required for long-term performance.

- If your primary focus is a standard, low-cost application: A conventional elastomeric O-ring is likely a more cost-effective choice for static, ambient temperature, and low-pressure conditions with compatible fluids.

Ultimately, selecting a spring energized seal is a strategic decision to engineer reliability into a system facing conditions that exceed the limits of conventional sealing technology.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Compatibility | Virtually inert to all industrial chemicals and aggressive media. |

| Temperature Range | Performs from cryogenic (-425°F / -254°C) to high heat (575°F / 300°C). |

| High-Pressure Capability | Handles extreme pressures, with some designs rated over 30,000 psi. |

| Low Friction & High Speed | Enables high-speed dynamic service and dry-running without lubrication. |

| Immunity to Compression Set | Spring ensures constant sealing force, preventing permanent deformation. |

Engineer Uncompromising Reliability with KINTEK's PTFE Sealing Solutions

Do you face sealing challenges involving extreme temperatures, aggressive chemicals, or high-pressure, high-speed dynamic motion? Standard elastomeric seals often fail in these demanding conditions, leading to costly downtime and equipment failure.

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including spring energized seals, for the semiconductor, medical, laboratory, and industrial sectors. We partner with you to provide custom sealing solutions—from rapid prototyping to high-volume production—that are engineered to withstand your most critical operating environments.

Let us help you solve your toughest sealing challenges. Contact our engineering team today to discuss your application requirements and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments