When material purity and chemical resistance are non-negotiable, PTFE gaskets are the default sealing solution. They are particularly indispensable in the chemical, pharmaceutical, food and beverage, and medical industries due to their unique combination of chemical inertness, wide temperature stability, and compliance with stringent purity standards.

The suitability of a PTFE gasket is defined not by the industry itself, but by the demanding conditions within it. Its value comes from its ability to provide a reliable seal in environments where chemical attack, contamination, or temperature extremes would cause other materials to fail.

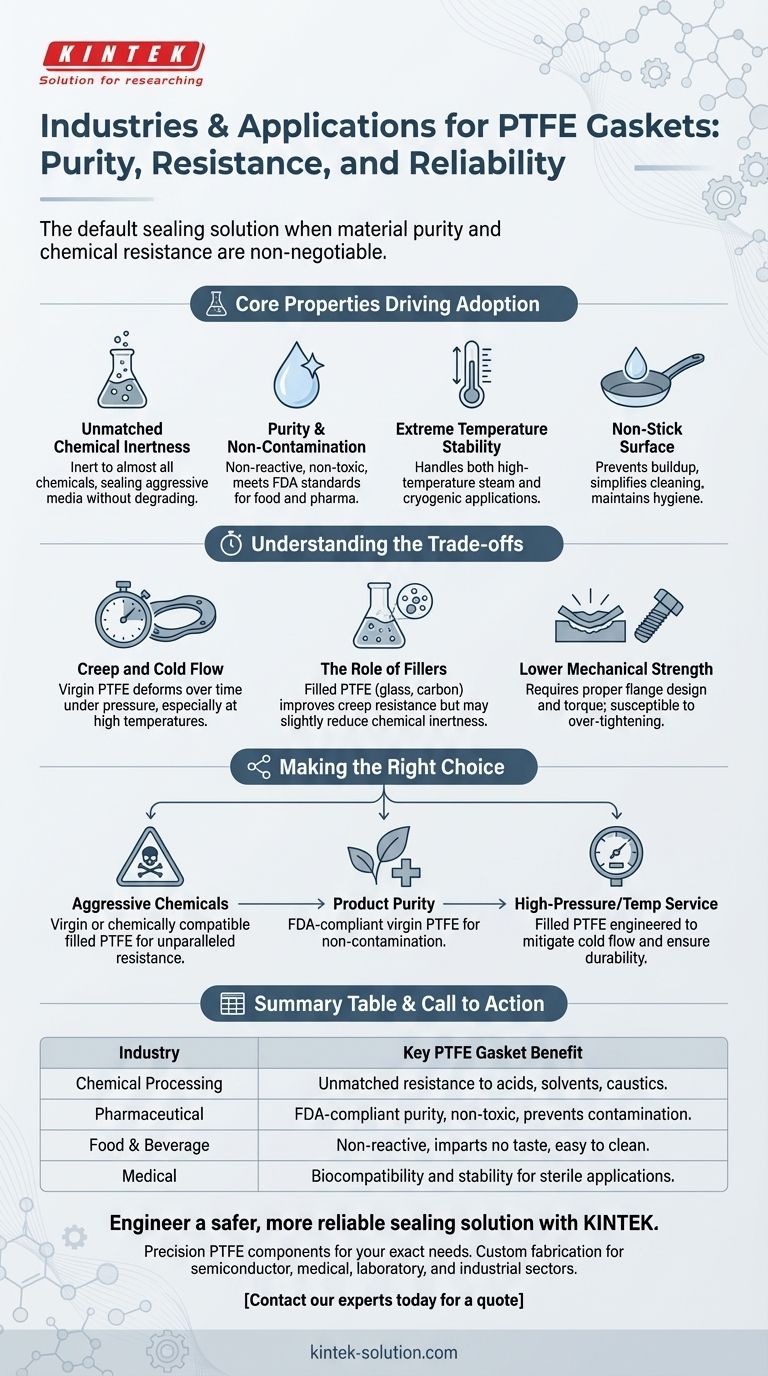

The Core Properties Driving PTFE Adoption

The widespread use of PTFE gaskets is not accidental. It is a direct result of a few fundamental material properties that make it uniquely suited for severe service applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. It can reliably seal aggressive media such as caustic chemicals, strong acids, solvents, hydrocarbons, and refrigerants without degrading.

This property makes it essential in chemical processing, where a gasket failure could lead to dangerous leaks and catastrophic equipment damage.

Purity and Non-Contamination

For industries like food, beverage, and pharmaceuticals, the primary concern is product purity. PTFE is non-reactive, non-toxic, and does not impart any taste, color, or contaminants into the process media.

Many grades of PTFE gaskets meet FDA standards, guaranteeing they are safe for direct contact with food and pharmaceutical products, ensuring process integrity from start to finish.

Extreme Temperature Stability

PTFE maintains its integrity across an exceptionally wide temperature range. This allows it to be used in processes involving high-temperature steam as well as in cryogenic applications.

This versatility reduces the need to specify different gasket materials for different temperature zones within a single facility, simplifying inventory and maintenance.

Non-Stick Surface

The famous non-stick quality of PTFE is a significant advantage in processing applications. It prevents material from building up on the gasket surface.

This is critical in food and pharmaceutical manufacturing, as it simplifies cleaning, prevents cross-contamination between batches, and maintains a hygienic processing environment.

Understanding the Trade-offs of PTFE Gaskets

While PTFE is a superior material for many applications, it is not without limitations. Acknowledging these trade-offs is key to using it effectively.

The Challenge of Creep and Cold Flow

The primary weakness of pure, or "virgin," PTFE is its tendency to creep or cold flow. This is the process where the material slowly deforms over time when subjected to pressure, which can lead to a loss of bolt torque and potential leaks.

This effect is more pronounced at elevated temperatures and can limit the use of virgin PTFE in certain high-pressure, high-temperature applications.

The Role of Fillers

To counteract cold flow and enhance mechanical properties, PTFE is often blended with filler materials. Common fillers include glass, carbon, and silica.

Filled PTFE gaskets offer significantly improved resistance to creep, higher compressive strength, and better wear characteristics. However, the addition of a filler can sometimes slightly reduce the overall chemical resistance of the gasket, a factor that must be considered for the specific application.

Lower Mechanical Strength

Compared to metallic or semi-metallic gaskets, PTFE is a much softer material. It cannot withstand the same compressive loads.

This means proper flange design and bolt torque procedures are critical. Over-tightening a PTFE gasket can easily crush the material, destroying its ability to create a reliable seal.

Making the Right Choice for Your Application

Selecting the correct PTFE gasket requires matching the material's properties to your primary operational goal.

- If your primary focus is handling aggressive chemicals: Virgin or chemically compatible filled PTFE provides unparalleled resistance, preventing dangerous leaks and equipment corrosion.

- If your primary focus is product purity (Food, Pharma): Specify an FDA-compliant virgin PTFE gasket to guarantee non-contamination and maintain sterile conditions.

- If your primary focus is high-pressure or high-temperature service: Select a filled PTFE gasket specifically engineered to mitigate cold flow and ensure a durable, long-lasting seal.

Understanding these core principles allows you to engineer a safer, more reliable, and more efficient sealed system.

Summary Table:

| Industry | Key PTFE Gasket Benefit |

|---|---|

| Chemical Processing | Unmatched resistance to aggressive acids, solvents, and caustics. |

| Pharmaceutical | FDA-compliant purity, non-toxic, and prevents contamination. |

| Food & Beverage | Non-reactive, imparts no taste or odor, easy to clean. |

| Medical | Biocompatibility and stability for sterile applications. |

Engineer a safer, more reliable sealing solution with KINTEK.

Whether your priority is handling aggressive chemicals, guaranteeing product purity, or withstanding high-pressure service, KINTEK's precision PTFE components are engineered to meet your exact needs. We specialize in custom fabrication—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors.

Contact our experts today to discuss your specific application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance