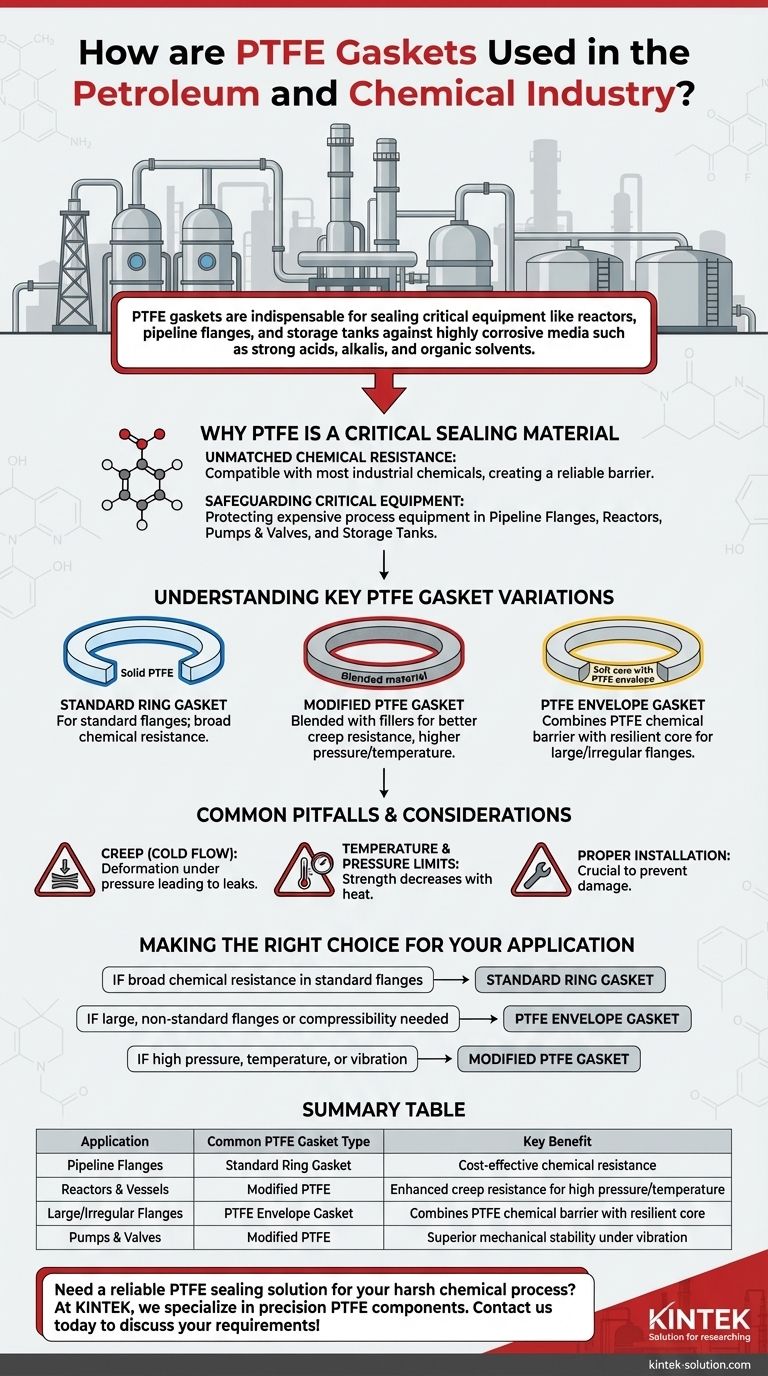

In the petroleum and chemical industries, PTFE gaskets are indispensable for sealing critical equipment like reactors, pipeline flanges, and storage tanks. Their primary function is to create a reliable, leak-proof seal in environments containing highly corrosive media—such as strong acids, alkalis, and organic solvents—where most other materials would quickly degrade and fail.

The core reason for PTFE's dominance in these sectors is its near-universal chemical inertness. However, understanding the mechanical limitations of pure PTFE and knowing when to use modified or composite versions is crucial for ensuring long-term operational safety and integrity.

Why PTFE is a Critical Sealing Material

The harsh conditions inside chemical plants and refineries demand materials that can withstand constant chemical attack without compromising their sealing capability.

Unmatched Chemical Resistance

PTFE is compatible with the vast majority of industrial chemicals. This makes it a "default" safe choice for applications involving aggressive media.

It provides a reliable barrier against strong acids, caustic alkalis, and volatile organic solvents, preventing leaks that could lead to equipment failure, environmental damage, or safety hazards.

Safeguarding Critical Equipment

By preventing leaks, PTFE gaskets protect the integrity of expensive and essential process equipment.

They are used extensively in:

- Pipeline Flanges: Ensuring a tight seal between sections of pipe transporting corrosive fluids.

- Reactors and Vessels: Sealing access points and connections on chemical reactors where internal conditions are extreme.

- Pumps and Valves: Preventing process fluid from escaping along valve stems or pump casings.

- Storage Tanks: Sealing nozzles and manways on tanks holding raw materials or finished chemical products.

Understanding Key PTFE Gasket Variations

Not all PTFE gaskets are the same. The form factor is chosen based on the specific mechanical and chemical demands of the application.

Standard Ring Gaskets

These are the most common form, cut from a sheet of solid PTFE. They are used for sealing standard-sized flanges and fittings in a wide range of chemical-resistant applications.

Modified PTFE Gaskets

Standard PTFE can be blended with filler materials (like glass or carbon) to create a "modified PTFE." This process enhances its mechanical properties.

These enhanced gaskets offer better resistance to creep (cold flow) and can handle higher pressures and temperatures, making them suitable for more demanding service in pumps, valves, and control equipment.

PTFE Envelope Gaskets

An envelope gasket consists of a soft, compressible core material (like rubber or a non-asbestos fiber) encased in a thin "envelope" of pure PTFE.

This design combines the superior chemical resistance of PTFE with the mechanical strength and resilience of the core material. They are ideal for sealing large or irregular flange surfaces where a solid PTFE gasket might not conform properly.

Common Pitfalls and Considerations

While chemically robust, PTFE has specific mechanical characteristics that must be understood to prevent gasket failure.

The Challenge of Creep (Cold Flow)

PTFE is a relatively soft material. Under the sustained pressure of a bolted flange, it can slowly "flow" or deform over time, a phenomenon known as creep.

This can lead to a loss of bolt torque and, eventually, a leak. This is the primary reason modified PTFE and envelope gaskets exist—to mitigate this specific weakness.

Temperature and Pressure Limits

Every gasket material has a defined operating window for temperature and pressure. While PTFE performs well across a broad range of temperatures, its mechanical strength decreases as it gets hotter, making it more susceptible to creep and extrusion.

Proper Installation is Non-Negotiable

The softness of PTFE makes it vulnerable to damage from flange surface imperfections or over-tightening. Proper bolt-torquing procedures are essential to create a durable seal without crushing or damaging the gasket material.

Making the Right Choice for Your Application

Selecting the correct PTFE gasket is a matter of matching the material's properties to the operational demands of the system.

- If your primary focus is broad chemical resistance in standard flanges: A standard, pure PTFE ring gasket is often the most cost-effective and suitable choice.

- If you need to seal large, non-standard flanges or require better compressibility: A PTFE envelope gasket provides the chemical resistance you need with superior mechanical sealing properties.

- If your application involves high pressure, temperature cycling, or vibration: A modified PTFE gasket offers enhanced mechanical stability and resistance to creep, ensuring a more durable seal.

Ultimately, choosing the right gasket is a critical engineering decision that directly impacts the safety and reliability of your entire process.

Summary Table:

| Application | Common PTFE Gasket Type | Key Benefit |

|---|---|---|

| Pipeline Flanges | Standard Ring Gasket | Cost-effective chemical resistance |

| Reactors & Vessels | Modified PTFE | Enhanced creep resistance for high pressure/temperature |

| Large/Irregular Flanges | PTFE Envelope Gasket | Combines PTFE chemical barrier with resilient core |

| Pumps & Valves | Modified PTFE | Superior mechanical stability under vibration |

Need a reliable PTFE sealing solution for your harsh chemical process?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment maintains integrity against even the most aggressive media.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability to enhance your operational safety and reliability.

Contact us today to discuss your specific application requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications