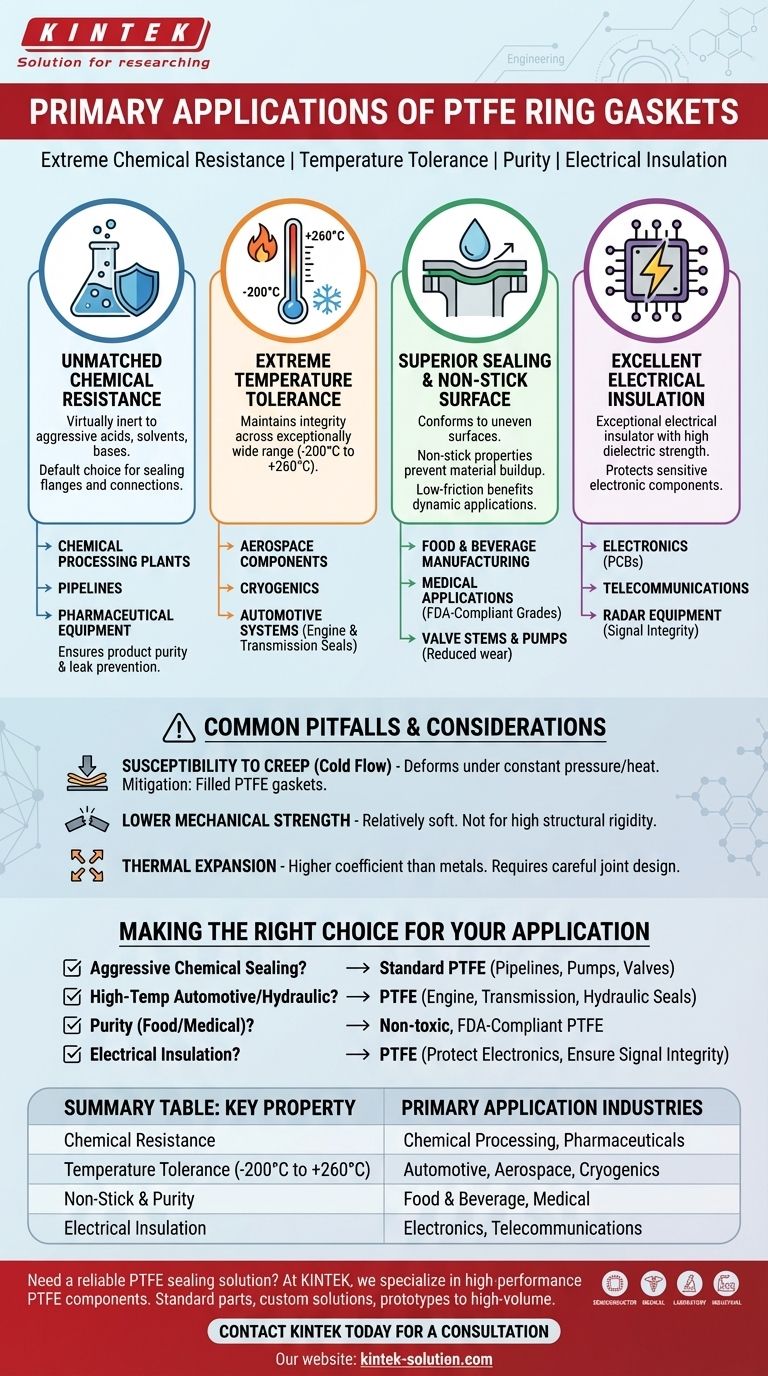

At its core, Polytetrafluoroethylene (PTFE) ring gaskets are primarily used in applications where extreme chemical resistance, temperature tolerance, and purity are non-negotiable. They are essential sealing components in aggressive industrial environments, including chemical processing, automotive systems, pharmaceutical manufacturing, and high-frequency electronics.

The widespread use of PTFE gaskets is not accidental. It is a direct result of the material's unique molecular structure, which provides a combination of chemical inertness, thermal stability, and low-friction properties that few other materials can match, making it a problem-solver for the most demanding sealing challenges.

The Core Properties Driving PTFE Adoption

To understand where PTFE gaskets are used, you must first understand why they are chosen. Their application is dictated by a unique set of material characteristics that make them indispensable in environments where other seals would quickly fail.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, solvents, and bases. This makes it the default choice for sealing flanges and connections in chemical processing plants, pipelines, and pharmaceutical equipment where product purity and leak prevention are critical.

Its corrosion resistance is also why it's used to line fuel hoses in the automotive industry, protecting the system from degradation over time.

Extreme Temperature Tolerance

PTFE gaskets maintain their integrity and sealing capability across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to 500°F).

This thermal stability makes them vital for both cryogenic applications and high-heat environments found in aerospace components, computer systems, and automotive parts like engine seals and transmission fluid seals.

Superior Sealing and Non-Stick Surface

The material is inherently flexible and can conform to uneven or imperfect flange surfaces, ensuring a tight seal. Its famous non-stick properties prevent material buildup, which is crucial in food and beverage manufacturing.

This low-friction surface also benefits dynamic applications like valve stems and pumps, reducing wear and extending service life.

Excellent Electrical Insulation

PTFE is an exceptional electrical insulator with a high dielectric strength. This property makes it ideal for protecting sensitive electronic components.

You will find PTFE used as insulation for printed circuit boards (PCBs) and in high-frequency applications like radar and telecommunications equipment, where signal integrity is paramount.

Common Pitfalls and Considerations

While PTFE is a superior sealing material, it is not a universal solution. Understanding its limitations is key to successful application and avoiding premature failure.

Susceptibility to Creep (Cold Flow)

Standard PTFE can be prone to "creep" or cold flow, meaning it can deform over time under constant pressure, especially at elevated temperatures. This can lead to a loss of bolt torque and potential leaks.

For high-pressure applications, this is often mitigated by using filled PTFE gaskets, which incorporate materials like glass or carbon to enhance mechanical strength and resistance to creep.

Lower Mechanical Strength

Compared to metallic or some elastomeric gaskets, pure PTFE is a relatively soft material. It is not suitable for applications requiring high structural rigidity. Its strength is in its chemical and thermal properties, not its mechanical load-bearing capacity.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. In applications with wide temperature swings, this difference must be accounted for in the joint design to maintain a consistent seal.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's strengths to the primary demand of your system.

- If your primary focus is aggressive chemical sealing: Standard PTFE is an excellent choice for its unparalleled chemical inertness in pipelines, pumps, and valves.

- If your primary focus is high-temperature automotive or hydraulic systems: PTFE's thermal stability makes it the reliable option for engine, transmission, and hydraulic seals.

- If your primary focus is purity for food or medical applications: Specify non-toxic, FDA-compliant PTFE grades to prevent contamination and leverage its non-stick surface.

- If your primary focus is electrical insulation: PTFE's high dielectric strength makes it a superior material for protecting sensitive electronics and ensuring signal integrity in communications equipment.

By understanding these core principles, you can confidently leverage PTFE's unique strengths for reliable, long-lasting sealing in the most demanding environments.

Summary Table:

| Key Property | Primary Application Industries |

|---|---|

| Chemical Resistance | Chemical Processing, Pharmaceuticals |

| Temperature Tolerance (-200°C to +260°C) | Automotive, Aerospace, Cryogenics |

| Non-Stick & Purity | Food & Beverage, Medical |

| Electrical Insulation | Electronics, Telecommunications |

Need a reliable PTFE sealing solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision seals, liners, and custom labware. Whether you require standard parts or custom-fabricated solutions—from prototypes to high-volume orders—we deliver the precision and material excellence your industry demands.

Our expertise supports the semiconductor, medical, laboratory, and industrial sectors. Let us help you solve your toughest sealing challenges with a component designed for longevity and performance.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability