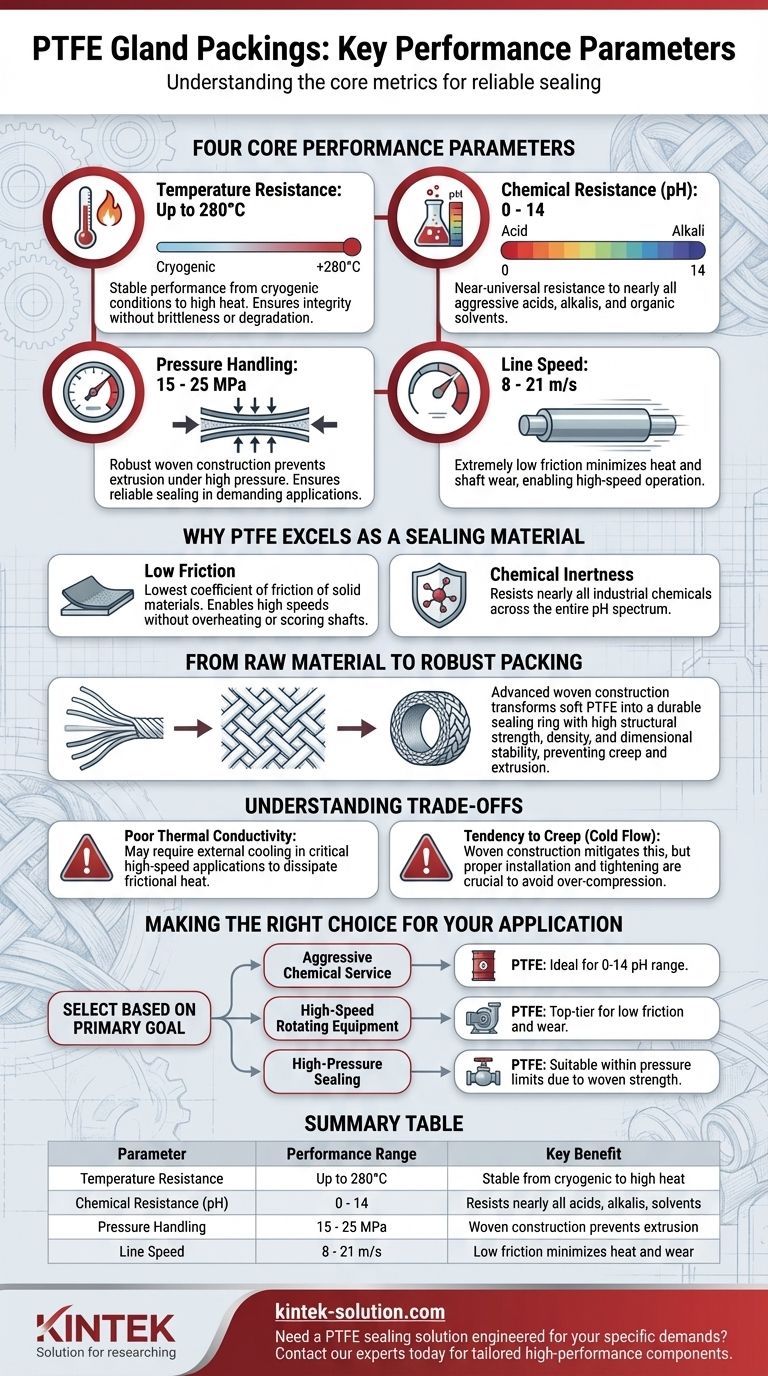

At its core, PTFE gland packing performance is defined by four key parameters. These are its ability to withstand temperatures up to 280°C, its near-universal chemical resistance across the entire 0-14 pH scale, its capacity to handle pressures between 15 and 25 MPa, and its suitability for high line speeds from 8 to 21 m/s.

The exceptional performance numbers of PTFE packing are not arbitrary; they are a direct outcome of PTFE's fundamental material properties—low friction and chemical inertness—which are then enhanced by advanced woven constructions to manage high pressure and ensure structural integrity.

Why PTFE Excels as a Sealing Material

To understand the performance parameters, you must first understand the unique characteristics of the Polytetrafluoroethylene (PTFE) polymer itself. These intrinsic properties make it one of the most versatile sealing materials available.

Unmatched Chemical Inertness (The 0-14 pH Range)

PTFE is famous for being chemically inert. It is resistant to nearly all industrial chemicals, including the most aggressive acids, alkalis, and organic solvents.

This is why its specified pH range is 0 to 14—it effectively covers the entire spectrum, ensuring the packing will not degrade or fail when exposed to corrosive media.

Extremely Low Friction (Enabling High Speeds)

PTFE has the lowest coefficient of friction of any known solid material, making it incredibly slippery. In a gland packing application, this translates directly to performance.

Low friction means less heat is generated between the packing and the rotating shaft of a pump. This reduction in frictional heat is what allows for high line speeds of 8 to 21 m/s without causing the packing to burn or scoring the shaft.

Wide Thermal Stability (The Temperature Range)

The PTFE polymer is thermally stable across a very broad temperature range, from cryogenic conditions up to +260°C or even 280°C for finished packing products.

This inherent stability ensures the packing material maintains its integrity and sealing capability without becoming brittle at low temperatures or degrading at high temperatures common in industrial processes.

From Raw Material to Robust Packing

While the raw properties of PTFE are excellent, they are not sufficient to handle high-pressure sealing alone. Modern PTFE packings are engineered products that overcome the material's natural limitations.

The Role of Woven Construction

PTFE packing is not a solid block of material. It is typically woven from multiple PTFE yarns that have been stretched and sintered (a process to impart strength).

This woven structure provides high structural strength and density, transforming the soft, formable polymer into a robust and durable sealing ring.

Achieving High Pressure Resistance

The primary benefit of the woven construction is its resistance to compression and extrusion. This is what enables the high pressure ratings of 15 to 25 MPa.

Under pressure, the strong, interlocked fibers prevent the softer PTFE material from being squeezed or "extruded" out of the gland, which would cause a seal failure.

Ensuring Dimensional Stability

The weaving and sintering process also gives the packing excellent dimensional stability. It resists stretching or deforming under the continuous mechanical stress of a pump or valve, ensuring a consistent and reliable seal over time.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of PTFE is critical for correct application and avoiding premature failure.

Poor Thermal Conductivity

While PTFE withstands high temperatures, it is a poor conductor of heat. It acts as an insulator, trapping the frictional heat it generates.

Even with its low friction, at the highest end of its speed and pressure range, this trapped heat can become an issue. In some critical high-speed applications, external flush or cooling may be necessary to dissipate heat and prevent damage.

Tendency to Creep (Cold Flow)

In its raw form, PTFE has a tendency to "creep" or "cold flow"—meaning it slowly deforms over time when placed under a constant load.

The woven construction of gland packing is specifically designed to mitigate this weakness. However, it's essential to follow proper installation and gland tightening procedures to avoid over-compressing the packing, which can accelerate this effect.

Making the Right Choice for Your Application

Use these performance parameters to match the packing to your specific operational goal.

- If your primary focus is aggressive chemical service: PTFE is an ideal choice due to its near-universal chemical resistance across the 0-14 pH range.

- If your primary focus is high-speed rotating equipment: PTFE's exceptionally low friction makes it a top-tier option for pumps where minimizing heat and shaft wear is critical.

- If your primary focus is high-pressure static or dynamic sealing: The high structural strength of woven PTFE packing makes it suitable for demanding valve and pump applications within its specified pressure limits.

Understanding these parameters empowers you to select a seal not just based on numbers, but on a clear knowledge of how the material will behave in your equipment.

Summary Table:

| Parameter | Performance Range | Key Benefit |

|---|---|---|

| Temperature Resistance | Up to 280°C | Stable performance from cryogenic to high heat |

| Chemical Resistance (pH) | 0 - 14 | Resists nearly all aggressive acids, alkalis, and solvents |

| Pressure Handling | 15 - 25 MPa | Robust woven construction prevents extrusion |

| Line Speed | 8 - 21 m/s | Extremely low friction minimizes heat and wear |

Need a PTFE sealing solution engineered for your specific demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gland packings, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication—from prototypes to high-volume orders—ensure you get a seal that delivers on these key parameters.

Contact our experts today to discuss your application and receive a tailored solution that maximizes reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- In what types of environments should PTFE seals be considered? Ensure Reliability in Extreme Conditions

- What are the main materials used in conventional oil seals and PTFE oil seals? Choose the Right Seal for Your Application

- What are PTFE oil seals and what makes them unique? Superior Sealing for Extreme Conditions

- What are O-rings and why are they commonly used? A Guide to Simple, Reliable Sealing

- What are the properties of PTFE Lip Seals when blended with fillers? Enhance Performance for Demanding Seals

- How is Teflon gland packing manufactured? A Guide to Durable, Custom Seals

- What are the benefits of PTFE bushes being self-lubricating? Achieve Maintenance-Free, High-Efficiency Motion

- What is a PTFE spacer and what problem does it solve? Achieve Leak-Free Seals in Demanding Environments