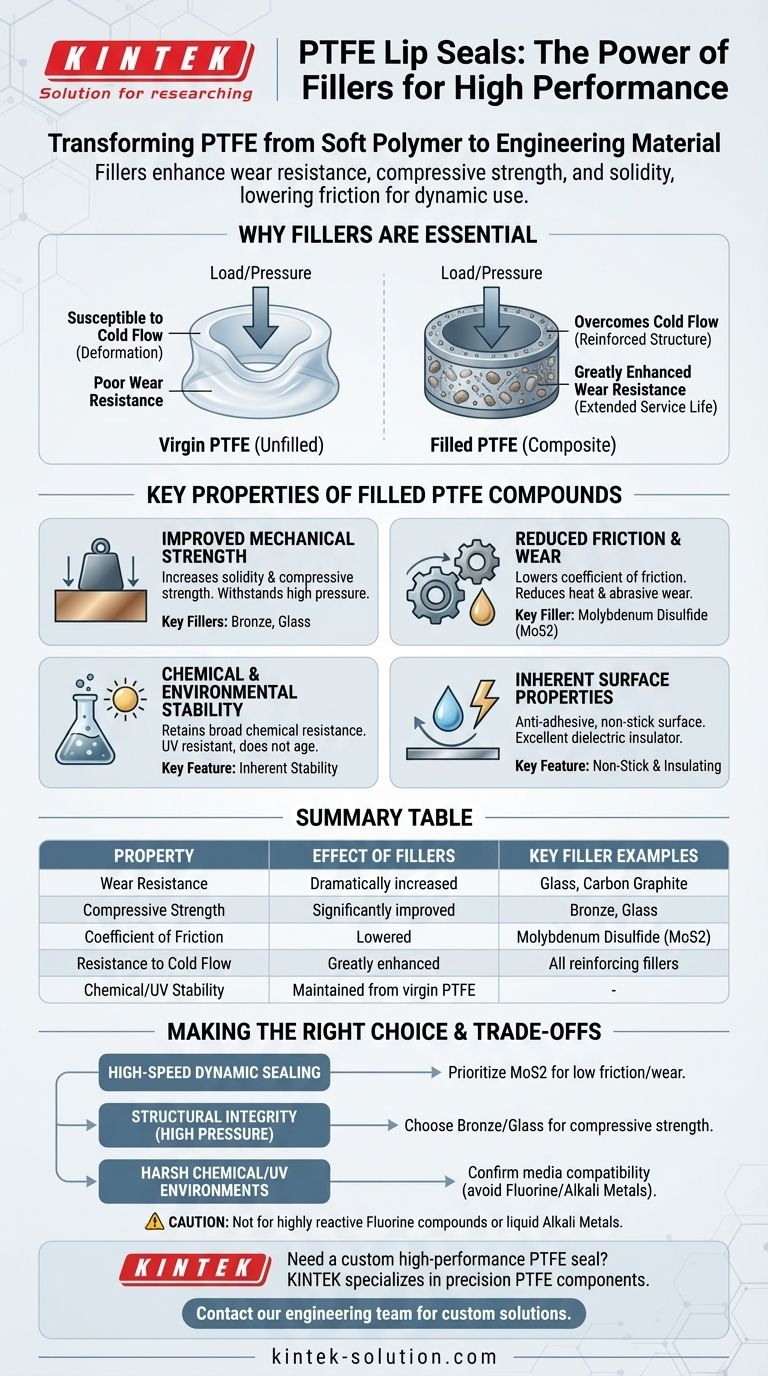

Adding fillers to Polytetrafluoroethylene (PTFE) is the critical step that transforms it from a soft, general-purpose polymer into a high-performance engineering material for lip seals. These fillers fundamentally enhance PTFE's mechanical properties, dramatically improving wear resistance, compressive strength, and solidity while lowering its coefficient of friction for demanding dynamic applications.

The core purpose of adding fillers to PTFE is to overcome its inherent softness and tendency to deform under load. This creates a robust composite material engineered for superior performance and a long operational life in challenging sealing environments.

Why Fillers are Essential for PTFE Seals

Unfilled, or "virgin," PTFE is an exceptionally slick and chemically inert material. However, it has significant mechanical weaknesses that make it unsuitable for most dynamic sealing applications on its own.

Overcoming Material Deformation (Cold Flow)

Pure PTFE is susceptible to cold flow, a phenomenon where the material slowly deforms or "creeps" over time when subjected to sustained pressure. Fillers add a reinforcing structure, significantly increasing the material's resistance to this deformation.

Enhancing Wear Resistance

In dynamic applications involving a rotating shaft, pure PTFE would wear away very quickly. Fillers create a composite matrix that is far more durable, drastically extending the seal's service life.

Key Properties of Filled PTFE Compounds

By blending specific additives into the PTFE base, we can tailor the final material to exhibit a range of superior properties well beyond those of the virgin polymer.

Improved Mechanical Strength

Fillers like bronze or glass increase the solidity and compressive strength of the PTFE. This makes the seal harder and better able to withstand high pressures without extruding from its groove.

Reduced Friction and Wear

Additives such as molybdenum disulfide (MoS2) act as a dry lubricant within the material itself. This lowers the coefficient of friction, reducing heat generation and abrasive wear against the shaft, which is critical for high-speed dynamic seals.

Broad Chemical and Environmental Stability

Filled PTFE retains the base polymer's outstanding resistance to most media. It is also inherently UV resistant and does not age or embrittle over time, ensuring long-term material stability in exposed conditions.

Inherent Surface Properties

The material maintains an anti-adhesive, non-stick surface, which helps prevent contamination buildup. It also possesses excellent dielectric properties, making it a superb electrical insulator.

Understanding the Trade-offs

While filled PTFE is a versatile solution, it is not universally compatible. Understanding its limitations is key to successful implementation.

Chemical Compatibility Exceptions

Despite its excellent general resistance, filled PTFE is not recommended for use with highly reactive chemicals. Specifically, it should not be used with certain fluorine compounds and liquid alkali metals, as these can attack the material.

Filler Selection is Critical

The specific type of filler dictates the final properties of the seal. A glass-filled compound will have different temperature limits and abrasive characteristics than a bronze-filled one. The selection must be matched carefully to the application's media, temperature, and pressure.

Making the Right Choice for Your Application

Selecting the correct PTFE blend is about matching the material's strengths to your primary operational challenge.

- If your primary focus is high-speed dynamic sealing: Prioritize compounds containing fillers like molybdenum disulfide (MoS2) to minimize friction and wear.

- If your primary focus is structural integrity under high pressure: Choose blends with bronze or glass fillers to maximize compressive strength and prevent material creep.

- If your primary focus is operation in harsh chemical or UV environments: Confirm that the specific chemical media is compatible, as nearly all filled PTFE compounds offer excellent environmental stability.

Ultimately, leveraging filled PTFE allows you to harness the polymer's unique benefits while engineering a robust solution for demanding sealing challenges.

Summary Table:

| Property | Effect of Fillers | Key Filler Examples |

|---|---|---|

| Wear Resistance | Dramatically increased | Glass, Carbon Graphite |

| Compressive Strength | Significantly improved | Bronze, Glass |

| Coefficient of Friction | Lowered | Molybdenum Disulfide (MoS2) |

| Resistance to Cold Flow | Greatly enhanced | All reinforcing fillers |

| Chemical/UV Stability | Maintained from virgin PTFE | - |

Need a high-performance PTFE seal tailored to your specific challenges?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom lip seals. We understand that the right filler blend is critical for success in semiconductor, medical, laboratory, and industrial applications. Our experts will work with you to select or develop a compound that delivers optimal wear resistance, strength, and chemical compatibility for your unique needs—from prototypes to high-volume production.

Contact our engineering team today to discuss your application and discover how our custom PTFE solutions can enhance your equipment's reliability and service life.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are PTFE Bellows and what material are they made from? Discover the Key to Chemical Resistance & Flexibility

- What are the advantages of polyester-filled PTFE? A Guide to Superior Wear & Load Performance

- What are the different operation mechanisms for PTFE butterfly valves? Choose the Right Operator for Your System

- What factors should be considered when choosing a PTFE sheet? Select the Right Grade for Your Application

- What are the available configurations for PTFE envelope gaskets? Engineer the Perfect Seal for Your Application

- What are the advantages of using ePTFE sheets for gaskets? Superior Sealing for Demanding Conditions

- What is the cost consideration for PTFE washers? Achieve Lower Total Cost of Ownership

- What are PTFE encapsulated O-rings made of? A Hybrid Seal for Extreme Chemical Resistance