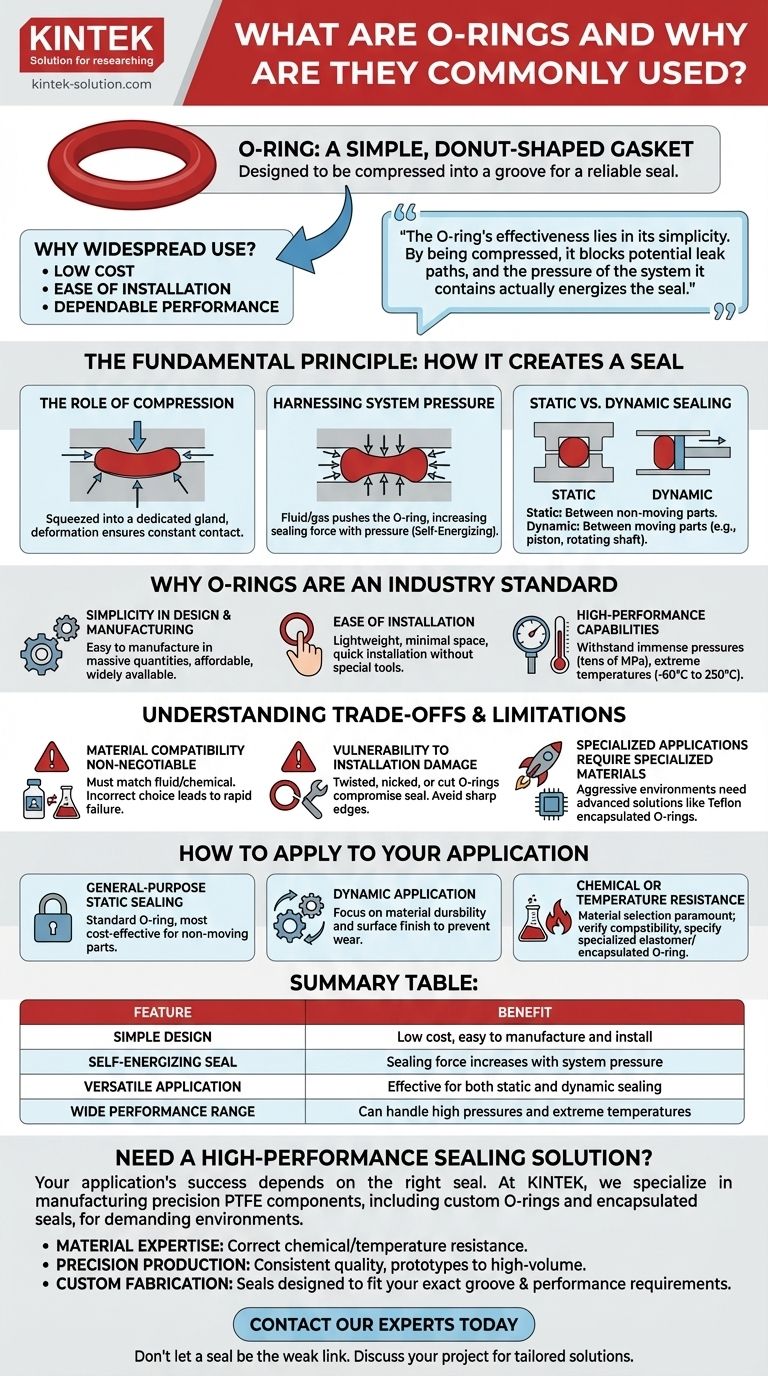

At its core, an O-ring is a simple, donut-shaped gasket designed to be compressed into a groove, creating a reliable seal between two parts. Its widespread use stems from an unmatched combination of low cost, ease of installation, and dependable performance across a vast range of temperatures and pressures.

The O-ring's effectiveness lies in its simplicity. By being compressed, it blocks potential leak paths, and the pressure of the system it contains actually energizes the seal, forcing it more tightly against the mating surfaces.

The Fundamental Principle: How an O-Ring Creates a Seal

An O-ring's function is straightforward but highly effective, relying on basic mechanical principles to prevent fluid or gas from escaping.

The Role of Compression

An O-ring is always designed to be squeezed into a dedicated groove, often called a gland. This initial compression deforms its circular cross-section, ensuring it maintains constant contact with the inner and outer walls of the space it seals.

Harnessing System Pressure

The key to its reliability under pressure is that the fluid or gas it contains pushes the O-ring against the surfaces. As system pressure increases, the sealing force also increases, making it a self-energizing seal.

Static vs. Dynamic Sealing

O-rings are versatile enough to be used in two primary scenarios.

- Static applications involve sealing between two components that do not move relative to each other, like the face of a flange or a container lid.

- Dynamic applications involve sealing between moving parts, such as a piston inside a hydraulic cylinder or a rotating shaft.

Why O-Rings Are an Industry Standard

The O-ring is a default choice in countless engineering designs for several clear, practical reasons.

Simplicity in Design and Manufacturing

Their simple geometry makes O-rings incredibly easy and inexpensive to manufacture in massive quantities, ensuring they are both affordable and widely available.

Ease of Installation

Compared to more complex sealing solutions, an O-ring is lightweight, takes up minimal space, and can be installed quickly with no special tools.

High-Performance Capabilities

Despite their simplicity, O-rings can withstand immense pressures, often measured in tens of megapascals. Specific materials also allow them to function in extreme temperatures, from as low as -60°C to as high as 250°C.

Understanding the Trade-offs and Limitations

While highly effective, an O-ring is not a universal solution. Understanding its limitations is critical for proper application.

Material Compatibility is Non-Negotiable

The single most important factor is choosing a material compatible with the fluid or chemical it will contact. For example, some materials that resist water and steam may quickly degrade when exposed to mineral oils or lubricants. An incorrect choice will lead to rapid seal failure.

Vulnerability to Installation Damage

The seal can be compromised if the O-ring is twisted, nicked, or cut during installation. Sharp edges on mating parts or improper lubrication are common causes of immediate leaks.

Specialized Applications Require Specialized Materials

In highly aggressive environments, standard O-rings are insufficient. Applications in chemical processing, aerospace, or semiconductor manufacturing often require advanced solutions like Teflon encapsulated O-rings to provide the necessary chemical and heat resistance.

How to Apply This to Your Application

Choosing the right sealing solution requires matching the component to the operational demands.

- If your primary focus is general-purpose static sealing: A standard O-ring is almost always the most cost-effective and reliable choice for non-moving parts.

- If your primary focus is a dynamic application: Pay close attention to the material's durability and the surface finish of the moving parts to prevent premature wear.

- If your primary focus is chemical or temperature resistance: Material selection is paramount; you must verify compatibility and often specify a specialized elastomer or encapsulated O-ring.

Ultimately, the O-ring remains a cornerstone of modern engineering because it provides a remarkably effective solution with elegant simplicity.

Summary Table:

| Feature | Benefit |

|---|---|

| Simple Design | Low cost, easy to manufacture and install |

| Self-Energizing Seal | Sealing force increases with system pressure |

| Versatile Application | Effective for both static and dynamic sealing |

| Wide Performance Range | Can handle high pressures and extreme temperatures |

Need a High-Performance Sealing Solution?

Your application's success depends on the right seal. At KINTEK, we specialize in manufacturing precision PTFE components, including custom O-rings and encapsulated seals, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors.

We ensure:

- Material Expertise: The correct chemical and temperature resistance for your specific media.

- Precision Production: Consistent quality and reliability, from prototypes to high-volume orders.

- Custom Fabrication: Seals designed to fit your exact groove dimensions and performance requirements.

Don't let a seal be the weak link in your design. Contact our experts today to discuss your project and get a solution tailored for reliability and performance.

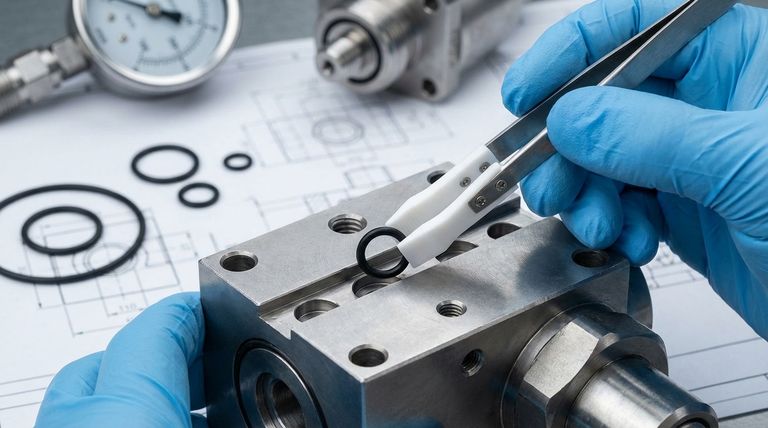

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What types of products can be made from PTFE sheets in the chemical industry? | Gaskets, Liners & Seals

- What are PTFE envelope gaskets? The Ultimate Sealing Solution for Corrosive Environments

- Under what conditions is the coefficient of friction minimized in PTFE slide bearings? Optimize for Low Friction

- How does the low friction property of PTFE fasteners benefit medical devices? Enhance Device Longevity and Patient Safety

- What are the key properties of Teflon sheets? A Guide to PTFE's Versatility

- What are the benefits of carbon-filled PTFE bushes? Boost Strength & Wear Resistance for Demanding Applications

- Why are Teflon bushes suitable for food and pharmaceutical manufacturing? Ensuring Purity and Safety

- In which industries are PTFE control valves commonly used? Essential for Corrosive & High-Purity Fluids