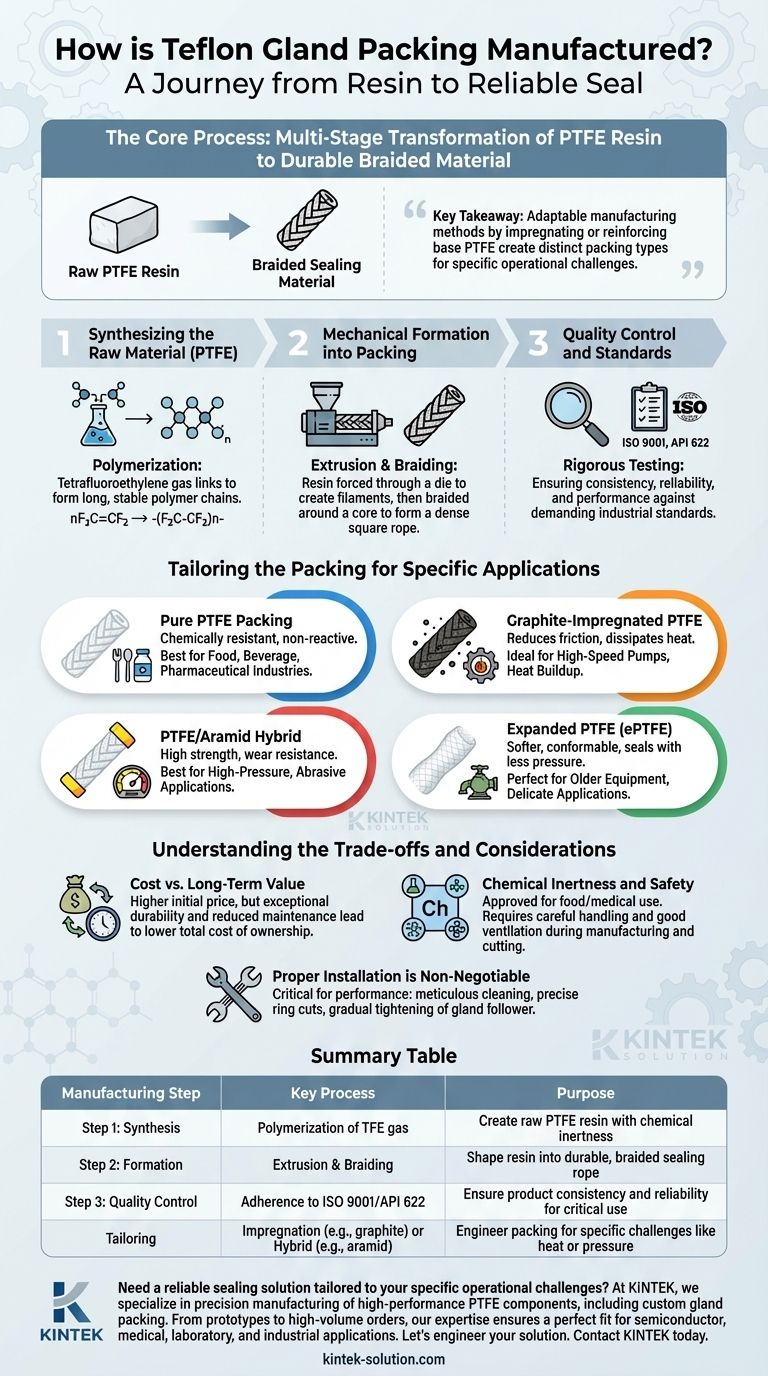

At its core, the manufacturing of Teflon gland packing is a multi-stage process that transforms raw Polytetrafluoroethylene (PTFE) resin into a durable, braided sealing material. This involves creating the base PTFE polymer, mechanically forming it through processes like extrusion and braiding, and implementing rigorous quality control to ensure it meets demanding industrial standards.

The key takeaway is not the single manufacturing method, but how that method is adapted. By impregnating the base PTFE with materials like graphite or reinforcing it with aramid fibers, manufacturers create distinct types of packing, each engineered to solve specific operational challenges like high temperatures, pressures, or abrasive media.

The Foundational Manufacturing Process

The journey from raw chemical to finished industrial seal involves distinct chemical and mechanical stages. Each step is critical to the final product's performance and reliability.

Step 1: Synthesizing the Raw Material (PTFE)

The process begins with the chemical polymerization of tetrafluoroethylene gas. Using a catalyst and high-pressure heating in a free-radical reaction, individual gas molecules (monomers) link together to form long, stable polymer chains.

This reaction, nF2C=CF2 → -(F2C-CF2)n-, creates the raw PTFE resin—the foundational material renowned for its extreme chemical inertness and low friction.

Step 2: Mechanical Formation into Packing

Once the PTFE resin is produced, it must be converted into a workable form. This is typically done through extrusion, where the resin is forced through a die to create long, continuous filaments or tapes.

These filaments are then braided together around a core to form the dense, square-cross-section rope characteristic of gland packing. The tightness and pattern of the braid directly influence the packing's density and pressure-handling capabilities.

Step 3: Quality Control and Standards

Throughout production, manufacturers adhere to strict quality management systems, such as ISO 9001, to ensure consistency and reliability.

For specific demanding applications, packing may be tested against standards like API 622, which evaluates sealing materials for performance, particularly in fugitive emissions service. This ensures the end product is trustworthy for critical industrial use.

Tailoring the Packing for Specific Applications

The true versatility of Teflon packing comes from modifying the base PTFE material during manufacturing to enhance specific properties.

Pure PTFE Packing

This is the most chemically resistant form, consisting of only braided PTFE. Its non-reactive and non-contaminating nature makes it the standard choice for applications in the food, beverage, and pharmaceutical industries.

Graphite-Impregnated PTFE Packing

In this variant, fine graphite particles are incorporated into the PTFE material before braiding. Graphite acts as a lubricant, reducing friction on the shaft and, more importantly, dissipating heat. This makes it ideal for high-speed pumps where heat buildup is a primary concern.

PTFE/Aramid Hybrid Packing

For high-pressure and abrasive applications, a hybrid construction is used. This packing often features corners or entire strands made of aramid fibers (like Kevlar), which provide exceptional strength and wear resistance. The PTFE provides the low-friction sealing surface, while the aramid provides the structural integrity.

Expanded PTFE (ePTFE) Packing

Expanded PTFE is a softer, more conformable material created by rapidly stretching PTFE under specific conditions. This flexibility allows it to create an excellent seal with less gland pressure, making it perfect for older equipment or applications requiring a delicate touch.

Understanding the Trade-offs and Considerations

While highly effective, choosing Teflon gland packing requires a clear understanding of its operational and financial implications.

Cost vs. Long-Term Value

Teflon gland packing typically has a higher initial purchase price compared to conventional materials like graphite or vegetable fiber packing.

However, its exceptional durability, reduced need for maintenance, and ability to prevent costly leaks and downtime often result in a significantly lower total cost of ownership over the equipment's lifecycle.

Chemical Inertness and Safety

The finished product is remarkably safe and chemically inert, which is why it's approved for food and medical use. During manufacturing, however, the chemicals involved require careful handling.

When handling or cutting the packing for installation, good ventilation should be ensured to avoid inhaling any dust particles.

Proper Installation is Non-Negotiable

The most advanced packing will fail if installed improperly. The manufacturing quality must be matched by installation quality. This involves meticulously cleaning the stuffing box, cutting precise rings with clean, angled joints, and tightening the gland follower evenly and gradually to avoid over-compression.

Making the Right Choice for Your Goal

Select your packing based on the primary challenge you need to solve.

- If your primary focus is extreme chemical resistance: Choose pure PTFE packing for its unparalleled inertness, especially in food, beverage, or pharmaceutical applications.

- If your primary focus is high-temperature or high-speed performance: Select graphite-impregnated PTFE packing to enhance heat dissipation and reduce friction.

- If your primary focus is high-pressure or abrasive media: A PTFE/aramid hybrid packing provides the necessary strength and wear resistance to prevent extrusion.

- If your primary focus is sealing older or slightly worn equipment: Expanded PTFE offers superior conformability to create a reliable seal with minimal gland pressure.

Ultimately, understanding how Teflon packing is manufactured and modified is the key to selecting a material that ensures operational reliability and long-term efficiency.

Summary Table:

| Manufacturing Step | Key Process | Purpose |

|---|---|---|

| Step 1: Synthesis | Polymerization of TFE gas | Create raw PTFE resin with chemical inertness |

| Step 2: Formation | Extrusion & Braiding | Shape resin into durable, braided sealing rope |

| Step 3: Quality Control | Adherence to ISO 9001/API 622 | Ensure product consistency and reliability for critical use |

| Tailoring | Impregnation (e.g., graphite) or Hybrid (e.g., aramid) | Engineer packing for specific challenges like heat or pressure |

Need a reliable sealing solution tailored to your specific operational challenges?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom gland packing. Whether you require the extreme chemical resistance of pure PTFE for semiconductor or laboratory applications, the heat dissipation of graphite-impregnated seals for industrial machinery, or the robust strength of PTFE/aramid hybrids for high-pressure environments, our expertise ensures a perfect fit.

We partner with clients across the semiconductor, medical, laboratory, and industrial sectors, delivering custom fabrication from prototypes to high-volume orders. Our commitment to quality means you get a seal that enhances operational reliability and reduces total cost of ownership.

Let's engineer your solution. Contact KINTEB today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the first step in both PTFE production methods? Unlocking the Key to High-Performance Polymer Manufacturing

- How does PTFE contribute to the sealing performance of ball valves? Achieve Leak-Free, Durable Sealing

- What additional advantages does expanded PTFE offer? Superior Sealing, Stability & Purity for Critical Applications

- What are the advantages of using PTFE combined with glass fiber aggregates? Achieve Superior Strength & Durability

- What temperature range can welded PTFE bellow seals withstand? Unmatched Performance from -200°C to +260°C

- What are the main technical features of PTFE rotary shaft seals? Unlock Extreme Performance & Reliability

- What standards do PTFE encapsulated O-rings meet for compression set? Ensure Long-Term Seal Reliability

- What is a PTFE gasket? The Ultimate Seal for Extreme Chemicals and Temperatures