At its core, a PTFE spacer is a specialized sealing component engineered from Polytetrafluoroethylene, a high-performance fluoropolymer. Its primary function is to create a durable, chemically resistant barrier between two mating surfaces, such as pipe flanges or equipment end covers, to effectively eliminate leaks of gas and liquid media in demanding industrial environments.

The crucial insight is that PTFE spacers are not merely washers; they are advanced sealing solutions that leverage the unique properties of PTFE to solve leakage problems in situations—like emergency repairs or imperfect surfaces—where traditional gaskets often fail.

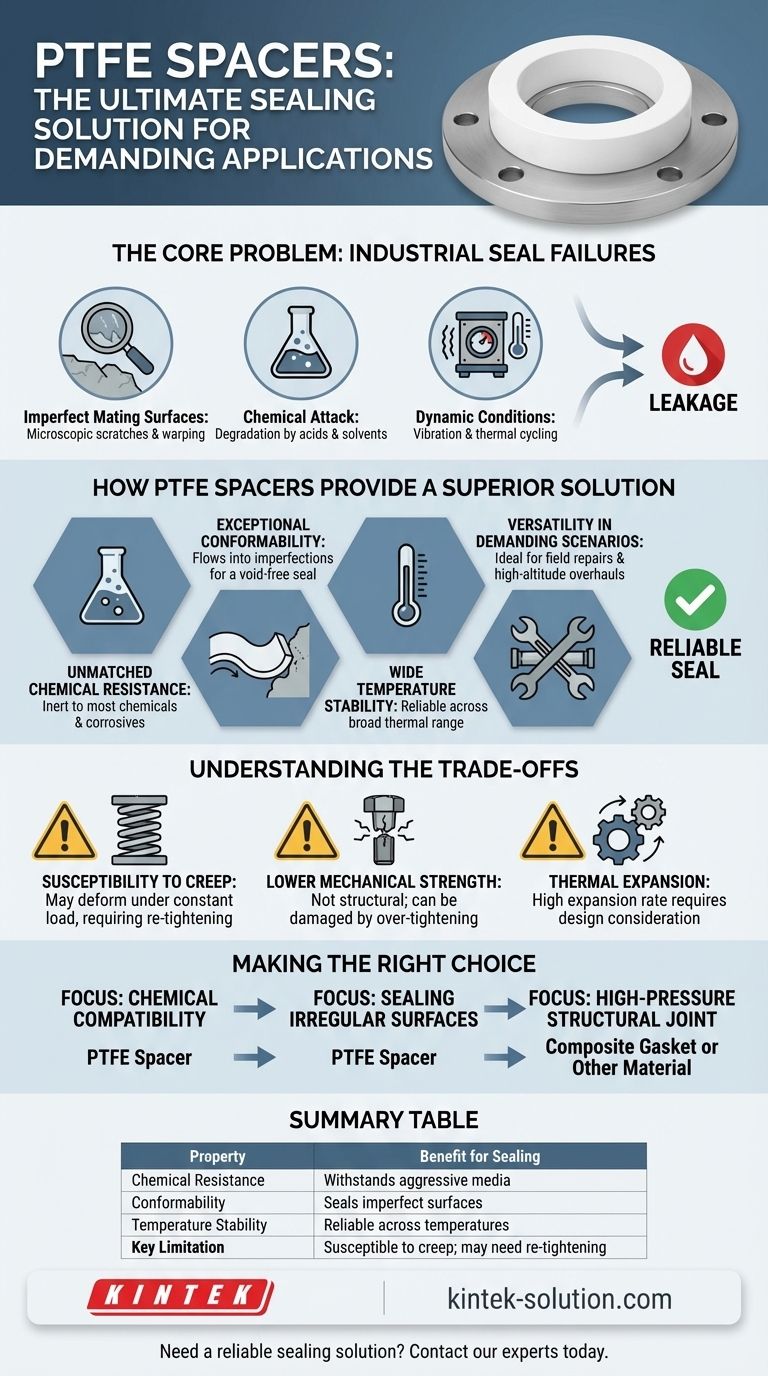

The Core Problem: Why Industrial Seals Fail

Before understanding the solution, it's essential to recognize the common points of failure in industrial sealing applications. Leaks are rarely a simple matter; they stem from complex environmental and mechanical challenges.

Imperfect Mating Surfaces

No two surfaces are perfectly flat. Flanges, tank covers, and equipment casings can have microscopic scratches, warping from heat, or corrosion, creating paths for media to escape.

Chemical Attack and Degradation

Many industrial processes involve aggressive acids, solvents, or gases. These media can chemically attack and degrade common gasket materials, causing them to swell, crack, or dissolve over time.

Dynamic Operating Conditions

Equipment is rarely static. Vibration, pressure fluctuations, and cycles of heating and cooling cause mating surfaces to expand and contract at different rates, constantly stressing the seal and creating potential leak points.

How PTFE Spacers Provide a Superior Solution

A PTFE spacer's effectiveness comes from the intrinsic properties of its material, which are uniquely suited to overcoming the challenges mentioned above.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert substances known. It is virtually immune to attack from most industrial chemicals, solvents, and corrosive agents, ensuring the seal's integrity is not compromised by the media it contains.

Exceptional Conformability

Due to its manufacturing process, a PTFE spacer is soft and can flow into the microscopic imperfections of mating surfaces when compressed. This creates a highly effective, void-free seal, even on surfaces that are not perfectly machined or have minor damage.

Wide Temperature Stability

PTFE maintains its properties across an exceptionally broad temperature range. It does not become brittle at low temperatures or degrade at high temperatures common in industrial processes, providing a reliable seal in fluctuating thermal conditions.

Versatility in Demanding Scenarios

The combination of these properties makes PTFE spacers ideal for difficult field applications. They are invaluable during on-site construction, emergency repairs, or overhauls of high-altitude pipelines where achieving a perfect seal quickly is critical.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its limitations to ensure proper application.

Susceptibility to Creep

Under a constant compressive load, especially at elevated temperatures, pure PTFE can slowly deform or "creep." This may lead to a loss of bolt torque over time, potentially requiring periodic re-tightening to maintain seal integrity.

Lower Mechanical Strength

PTFE is a relatively soft material. It is not a structural component and can be damaged by extreme over-tightening or cut by sharp flange edges. It is designed for sealing, not for bearing significant mechanical loads.

Thermal Expansion

The rate of thermal expansion for PTFE is significantly higher than for metals. In applications with extreme temperature swings, this difference must be accounted for in the joint design to maintain a consistent sealing pressure.

Making the Right Choice for Your Goal

Selecting the correct sealing component depends entirely on the specific demands of your application. Use these guidelines to make an informed decision.

- If your primary focus is chemical compatibility: A PTFE spacer is an ideal choice for containing aggressive or corrosive media where other materials would quickly fail.

- If your primary focus is sealing irregular or older surfaces: The excellent conformability of a PTFE spacer makes it highly effective for field repairs and retrofits on worn equipment.

- If your primary focus is a high-pressure structural joint with minimal maintenance: You may need to consider a composite gasket with a PTFE element or a different material entirely to mitigate creep.

Ultimately, understanding both the strengths and limitations of PTFE spacers empowers you to achieve a reliable, long-lasting seal in your most critical applications.

Summary Table:

| Property | Benefit for Sealing Applications |

|---|---|

| Chemical Resistance | Withstands aggressive acids, solvents, and corrosive media. |

| Conformability | Flows to seal imperfect or worn mating surfaces effectively. |

| Temperature Stability | Performs reliably across a wide range of temperatures. |

| Key Limitation | Susceptible to creep under constant load; may require re-tightening. |

Need a reliable sealing solution for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom spacers, seals, and liners. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a component that delivers superior leak-free performance, even in the most demanding conditions.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and function for your specific needs.

Contact our experts today to discuss your application and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications