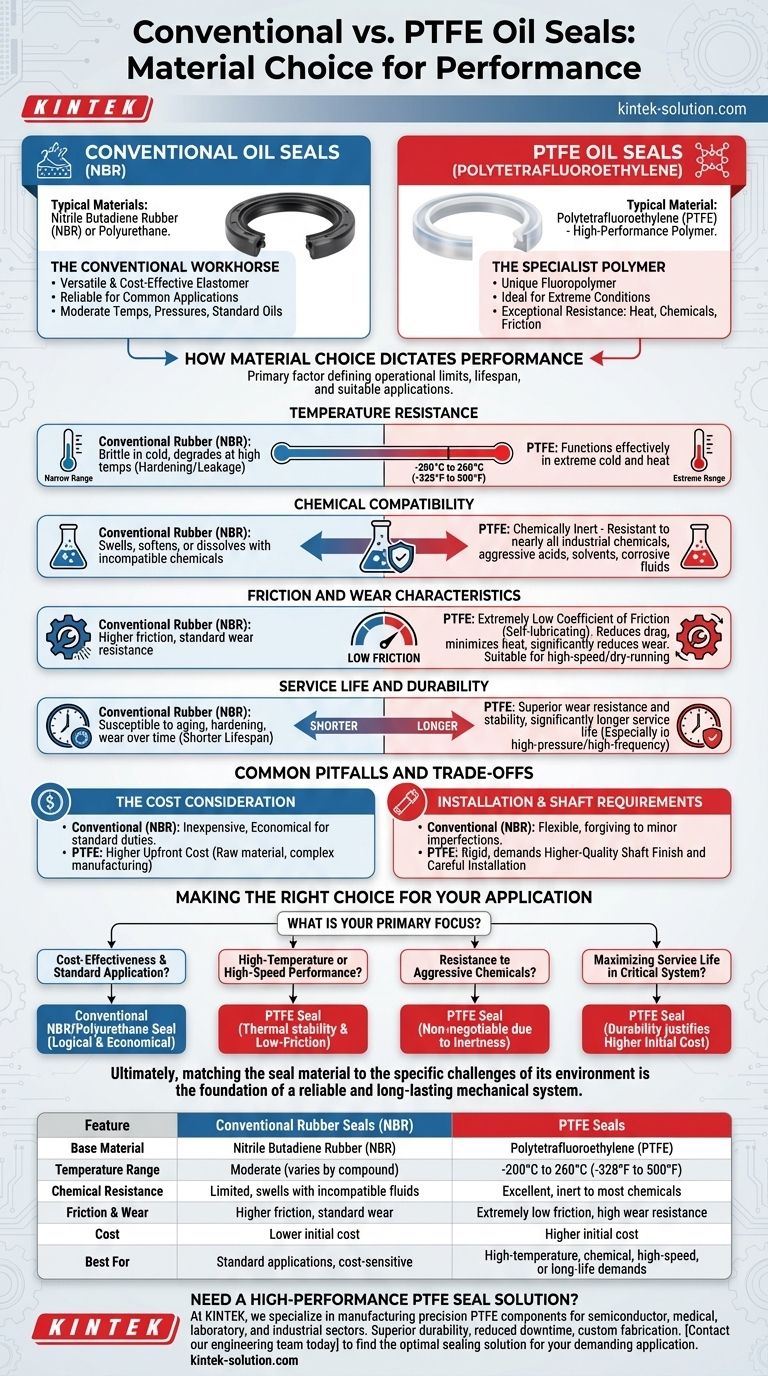

At their core, conventional oil seals are typically made from rubber compounds like Nitrile Butadiene Rubber (NBR) or polyurethane. In contrast, PTFE oil seals are manufactured from a high-performance polymer known as Polytetrafluoroethylene (PTFE), the same base material used in non-stick coatings.

The choice between a conventional rubber seal and a PTFE seal is a critical engineering decision. It is a trade-off between the cost-effective flexibility of rubber for standard duties and the superior durability and resistance of PTFE for demanding, high-performance environments.

How Material Choice Dictates Performance

The material an oil seal is made from is not an arbitrary detail; it is the primary factor that defines its operational limits, lifespan, and suitable applications. Understanding these differences is key to ensuring system reliability.

The Conventional Workhorse: Nitrile Rubber (NBR)

Most standard oil seals are made from Nitrile Butadiene Rubber (NBR). This material is a versatile and cost-effective elastomer.

It provides a reliable sealing solution for common applications involving moderate temperatures, pressures, and standard lubricating oils.

The Specialist Polymer: Polytetrafluoroethylene (PTFE)

PTFE is a synthetic fluoropolymer with a unique set of properties that make it ideal for extreme conditions where conventional rubber would quickly fail.

Its molecular structure gives it exceptional resistance to heat, chemicals, and friction, setting it apart as a premium sealing material.

Key Performance Differences Explained

The fundamental properties of rubber and PTFE create vastly different performance profiles.

Temperature Resistance

A critical differentiator is the operational temperature range. PTFE seals can function effectively in extreme cold and heat, typically from -200°C to 260°C (-328°F to 500°F).

Conventional rubber seals have a much narrower range and can become brittle in the cold or degrade rapidly when exposed to high temperatures, leading to hardening and leakage.

Chemical Compatibility

PTFE is chemically inert, meaning it is resistant to nearly all industrial chemicals, including aggressive acids, solvents, and corrosive fluids.

Rubber seals, on the other hand, can swell, soften, or dissolve when exposed to incompatible chemicals, causing seal failure. This makes PTFE the only viable choice for many chemical processing applications.

Friction and Wear Characteristics

One of PTFE's most valuable properties is its extremely low coefficient of friction. This self-lubricating nature reduces drag on the rotating shaft, minimizes heat generation, and significantly reduces wear.

This allows PTFE seals to be used in high-speed or even dry-running applications where a conventional rubber seal would overheat and fail.

Service Life and Durability

Due to its superior wear resistance and stability, a PTFE seal has a significantly longer service life, especially in high-pressure or high-frequency systems.

Conventional seals are more susceptible to aging, hardening, and wear over time, particularly in harsh environments, resulting in a comparatively shorter lifespan.

Common Pitfalls and Trade-offs

Choosing the right material requires understanding the limitations and costs associated with each option.

The Cost Consideration

There is a clear cost difference. Conventional rubber seals are inexpensive and suitable for a wide range of standard applications, making them the economical choice for less demanding roles.

PTFE seals have a higher upfront cost due to the raw material and a more complex manufacturing process that involves molding, heat treatment, and precise CNC machining.

Installation and Shaft Requirements

The physical properties of the materials affect installation. Rubber's flexibility is forgiving, allowing it to conform easily to minor imperfections on a shaft surface.

PTFE is a more rigid material. It demands a higher-quality shaft finish and more careful installation to ensure a proper seal and prevent damage.

Making the Right Choice for Your Application

Your selection should be dictated entirely by the operational demands of the system.

- If your primary focus is cost-effectiveness for a standard application: A conventional NBR or polyurethane seal is the most logical and economical choice.

- If your primary focus is high-temperature or high-speed performance: The thermal stability and low-friction properties of PTFE are essential for reliability.

- If your primary focus is resistance to aggressive chemicals: PTFE is non-negotiable due to its unmatched chemical inertness.

- If your primary focus is maximizing service life in a critical system: The durability and wear resistance of a PTFE seal justify its higher initial cost.

Ultimately, matching the seal material to the specific challenges of its environment is the foundation of a reliable and long-lasting mechanical system.

Summary Table:

| Feature | Conventional Rubber Seals (NBR) | PTFE Seals |

|---|---|---|

| Base Material | Nitrile Butadiene Rubber (NBR) | Polytetrafluoroethylene (PTFE) |

| Temperature Range | Moderate (varies by compound) | -200°C to 260°C (-328°F to 500°F) |

| Chemical Resistance | Limited, swells with incompatible fluids | Excellent, inert to most chemicals |

| Friction & Wear | Higher friction, standard wear resistance | Extremely low friction, high wear resistance |

| Cost | Lower initial cost | Higher initial cost |

| Best For | Standard applications, cost-sensitive projects | High-temperature, chemical, high-speed, or long-life demands |

Need a High-Performance PTFE Seal Solution?

Selecting the right seal material is critical for system reliability and longevity. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures you get a seal that delivers:

- Superior durability in extreme temperatures and harsh chemicals

- Reduced downtime with longer service life

- Custom fabrication from prototypes to high-volume orders

Let's discuss your specific requirements. Contact our engineering team today to find the optimal sealing solution for your demanding application.

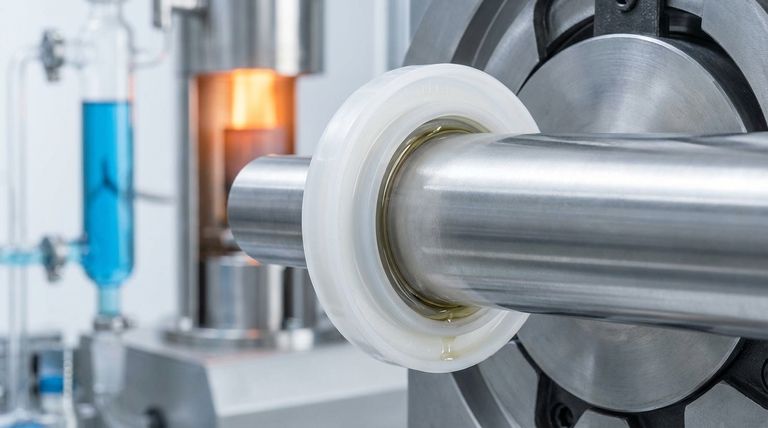

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability