In short, you should consider PTFE seals for aggressive environments where standard rubber seals would fail. These conditions are typically defined by extreme temperatures, exposure to harsh chemicals, high rotational speeds, or significant pressure, making PTFE the superior choice for demanding applications.

The decision to use a PTFE seal is driven by operational demands that exceed the capabilities of conventional elastomers. It is a material engineered for resilience in environments where heat, chemical attack, friction, and pressure would cause other seals to degrade and leak.

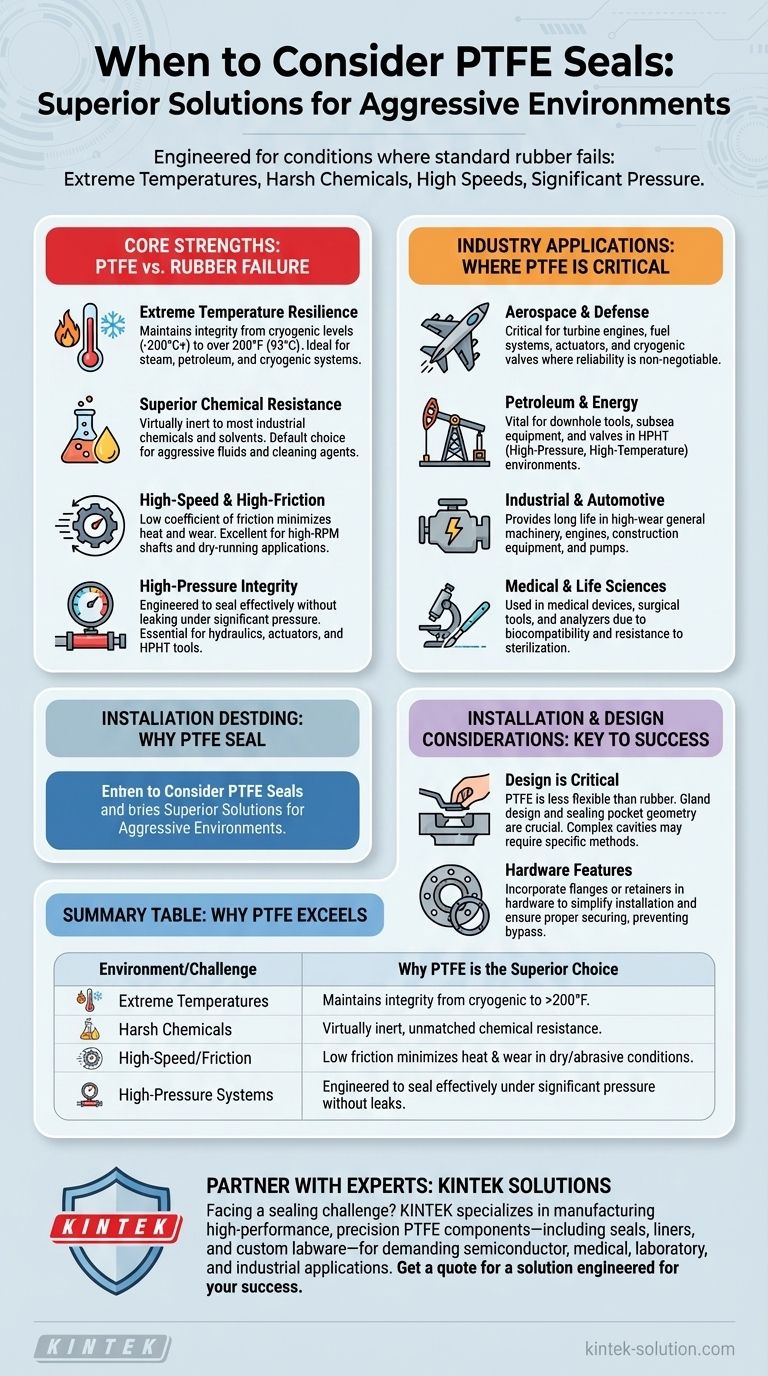

The Core Strengths of PTFE Seals

To understand when to use PTFE, it's essential to understand its fundamental properties. These seals excel where others fail due to a unique combination of material characteristics.

Extreme Temperature Resilience

PTFE seals maintain their integrity and sealing capability across an exceptionally wide temperature range. They are a common choice for petroleum or steam applications where temperatures exceed 200°F.

They are also used in cryogenic systems, demonstrating their effectiveness in both high-heat and extreme-cold environments.

Superior Chemical Resistance

PTFE is virtually inert to most industrial chemicals and corrosive compounds. This makes it the default choice for systems handling aggressive fluids that would quickly degrade rubber or other polymers.

This resistance is critical in the petroleum industry and in applications involving harsh cleaning agents or process chemicals.

High-Speed and High-Friction Performance

In high-speed rotating equipment, PTFE's low coefficient of friction minimizes heat generation and wear. This allows for reliable sealing in applications like high-RPM engines and industrial machinery.

It also performs exceptionally well in dry or abrasive environments where the lack of lubrication would destroy other seal types.

High-Pressure Integrity

PTFE seals are engineered to effectively seal mating surfaces without leaking, even when exposed to significant pressurized fluid or gas.

This makes them indispensable in hydraulic systems, actuators, and high-pressure, high-temperature (HPHT) downhole tools used in the energy sector.

Where These Strengths Are Critical: Industry Applications

The unique properties of PTFE make it a critical component in some of the world's most demanding industries.

Aerospace and Defense

In aerospace, reliability is non-negotiable. PTFE seals are used in jet engines, fuel systems, landing gear, flight controls, and hydraulic systems where they must withstand extreme temperatures and pressures.

Specific applications include turbine engine seals, fuel injectors, actuators, and cryogenic valves.

Petroleum and Energy

The oil and gas industry relies on PTFE for its durability in HPHT environments. You will find these seals in downhole tools, subsea equipment, and valves where chemical and thermal resistance is paramount.

Industrial and Automotive

In general machinery, PTFE seals provide long life in high-wear applications. They are used in automotive engines, construction equipment like excavators, and various industrial pumps and gearboxes.

Medical and Life Sciences

Due to its biocompatibility and resistance to sterilization processes, PTFE is used in medical devices. Applications include surgical tools, autoclaves, and hematology analyzers where purity and resilience are essential.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its unique nature requires specific design considerations that differ from flexible elastomers.

Installation and Design Considerations

PTFE is a plastic, not a rubber, meaning it is less flexible and forgiving during installation. The design of the sealing pocket or gland is critical for success.

Complex machined cavities may require the seal to be twisted or bent, which can make installation difficult and risk damage.

To ensure effective sealing and prevent bypass, hardware should incorporate features like flanges or retainers. These design elements simplify installation and properly secure the seal.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the specific demands of your environment.

- If your primary focus is high temperature or chemical exposure: PTFE is the superior choice for applications involving aggressive chemicals, steam, or temperatures consistently above 200°F.

- If your primary focus is high-speed or abrasive conditions: The low-friction nature of PTFE provides unmatched performance and longevity in high-RPM shafts and dry-running systems.

- If your primary focus is high-pressure sealing integrity: PTFE's resistance to deformation under load makes it essential for hydraulic systems, actuators, and pressurized gas applications.

Choosing the right seal is about matching the material's strengths to the challenges of your operational environment.

Summary Table:

| Environment/Challenge | Why PTFE is the Superior Choice |

|---|---|

| Extreme Temperatures | Maintains integrity from cryogenic levels to well over 200°F (93°C). |

| Harsh Chemicals | Virtually inert, offering unmatched resistance to corrosive fluids and solvents. |

| High-Speed / High-Friction | Low coefficient of friction minimizes heat and wear in dry or abrasive conditions. |

| High-Pressure Systems | Engineered to seal effectively without leaking under significant pressure. |

Facing a sealing challenge that standard elastomers can't handle?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and custom labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We deliver resilient solutions that ensure reliability, longevity, and peak performance in your critical operations. From custom prototypes to high-volume production, we are your partner for overcoming extreme environmental challenges.

Contact KINTEK today to discuss your specific requirements and get a quote for a sealing solution engineered for your success.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions