At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of extreme properties. Commonly known by the brand name Teflon, its defining characteristics are an exceptionally low coefficient of friction, near-total chemical inertness, a very wide operating temperature range, and excellent electrical insulation capabilities. These traits make it a material of choice for demanding industrial, chemical, and electrical applications.

PTFE is best understood as a material of extremes. Its remarkable non-stick, non-reactive, and heat-resistant properties make it invaluable, but these same qualities—particularly its softness and thermal expansion—introduce significant challenges in fabrication and structural applications.

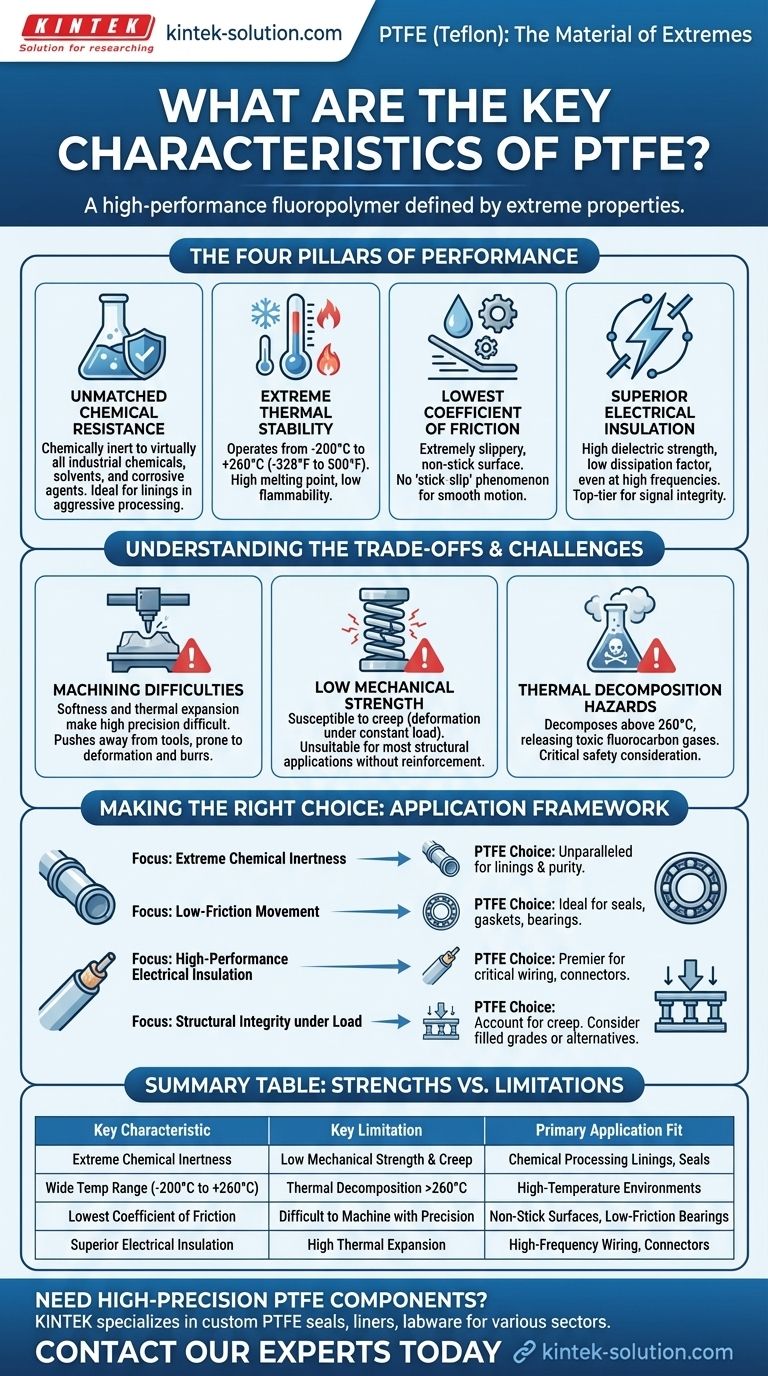

The Pillars of PTFE's Performance

To understand if PTFE is the right material for your project, you must first appreciate its four primary characteristics. These properties are the foundation of its performance in nearly every application.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It resists attack from virtually all industrial chemicals, solvents, and corrosive agents.

This exceptional inertness makes it an ideal material for lining pipes, tanks, and vessels used in aggressive chemical processing environments.

Extreme Thermal Stability

PTFE exhibits remarkable performance across a vast temperature spectrum, remaining functional from cryogenic conditions around -200°C (-328°F) up to a continuous service temperature of 260°C (500°F).

While its melting point is high (approximately 327°C or 621°F), it's the wide operating range that provides its true thermal utility. It also has very low flammability and is self-extinguishing.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it an extremely slippery, non-stick surface. This property is responsible for its use in everything from non-stick cookware to low-friction bearings.

This also means it exhibits no "stick-slip" phenomenon, where static friction is higher than dynamic friction. The result is perfectly smooth, continuous motion in sliding applications.

Superior Electrical Insulation

As a fluoropolymer, PTFE is an outstanding electrical insulator. It possesses a high dielectric strength and a low dissipation factor, even at high frequencies.

These properties make it a top-tier choice for insulating high-performance wires and cables, particularly in aerospace and computing where signal integrity is critical.

Understanding the Trade-offs and Practical Challenges

The extreme properties that make PTFE so useful also create specific limitations and handling challenges. Acknowledging these trade-offs is crucial for successful implementation.

Machining and Fabrication Difficulties

PTFE's unique combination of properties makes it notoriously difficult to machine with high precision.

Its softness and low friction cause it to push away from cutting tools rather than shearing cleanly. This can lead to deformation and burrs instead of a crisp cut.

Furthermore, its high thermal expansion coefficient means it changes size significantly with temperature variations during machining, making it a challenge to hold tight tolerances.

Low Mechanical Strength

PTFE is a relatively soft material with low tensile strength and structural rigidity compared to engineering plastics like nylon or PEEK.

It is susceptible to creep, which is the tendency to slowly deform over time when under a constant load. This makes pure PTFE unsuitable for most structural or high-load-bearing applications without reinforcement (e.g., glass or carbon-filled grades).

Thermal Decomposition Hazards

While stable up to 260°C, PTFE will begin to decompose at higher temperatures.

Above this threshold, it can release toxic fluorocarbon gases. This is a critical safety consideration for both the machining process and the end-use application's potential temperature excursions.

Making the Right Choice for Your Application

Use this framework to determine if PTFE's unique profile aligns with your primary engineering goal.

- If your primary focus is extreme chemical inertness or non-stick surfaces: PTFE is an unparalleled choice for lining pipes and vessels or creating release coatings where purity and cleanliness are essential.

- If your primary focus is low-friction movement: Its self-lubricating properties make it ideal for seals, gaskets, and bearings, especially where smooth, stick-slip-free motion is required.

- If your primary focus is high-performance electrical insulation: Its high dielectric strength and thermal stability make it a premier material for critical, high-frequency wiring and connectors.

- If your primary focus is structural integrity under a constant load: You must account for PTFE's softness and tendency to creep, and strongly consider using a filled grade or an alternative polymer.

Understanding both its exceptional strengths and its inherent limitations is the key to successfully leveraging PTFE in any design.

Summary Table:

| Key Characteristic | Key Limitation | Primary Application Fit |

|---|---|---|

| Extreme Chemical Inertness | Low Mechanical Strength & Creep | Chemical Processing Linings, Seals |

| Wide Temp Range (-200°C to +260°C) | Thermal Decomposition >260°C | High-Temperature Environments |

| Lowest Coefficient of Friction | Difficult to Machine with Precision | Non-Stick Surfaces, Low-Friction Bearings |

| Superior Electrical Insulation | High Thermal Expansion | High-Frequency Wiring, Connectors |

Need High-Precision PTFE Components for Your Demanding Application?

At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. We understand the unique challenges of machining PTFE and leverage our expertise to deliver precision parts that meet your exact specifications, from prototypes to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can enhance your product's performance, reliability, and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are the different grades of PTFE and their uses? A Guide to Selecting the Right Material

- How are PTFE coatings applied? A Guide to Spray, Electrostatic, and Dip-Spin Methods

- What is PTFE commonly known as and when was it developed? The 'Plastics King' for Extreme Performance

- How does PTFE benefit the semiconductor industry? Essential for High-Purity Chip Fabrication

- What are the general material properties of PTFE? Discover Its Extreme Chemical & Thermal Resistance

- What is PTFE and what are its general properties? A Guide to the Ultimate High-Performance Polymer

- What are the primary properties of Teflon that make it a 'powerhouse plastic'? Unlock Unmatched Performance