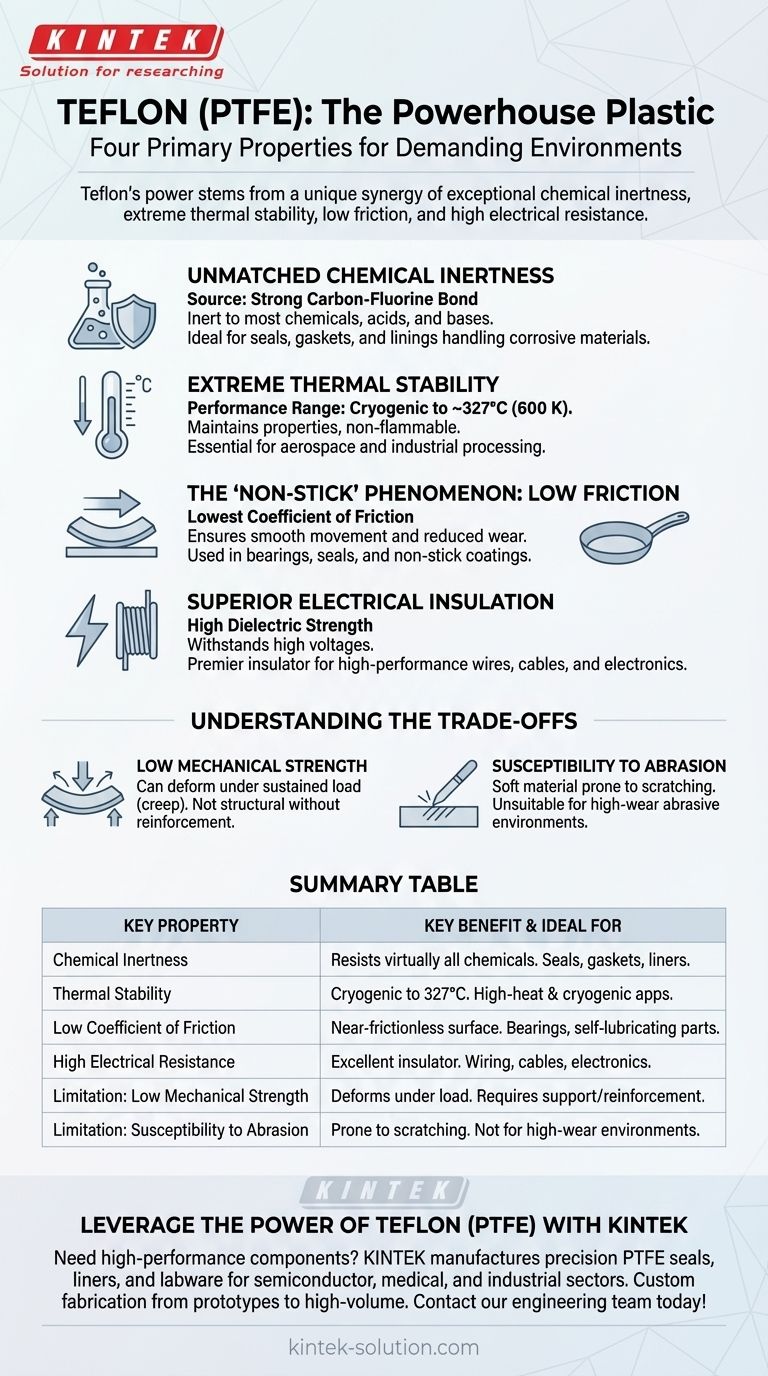

At its core, Teflon's power comes from a unique combination of four primary properties: exceptional chemical inertness, stability across a wide range of temperatures, an extremely low coefficient of friction, and high electrical resistance. These characteristics, rooted in its fluoropolymer chemistry, make it one of the most versatile and reliable materials for demanding environments.

The true strength of Teflon (PTFE) is not found in a single attribute but in the rare synergy of its properties. It simultaneously resists chemical attack, withstands extreme heat and cold, and provides a near-frictionless surface, a combination few other materials can match.

Unmatched Chemical Inertness

The Source of Its Resistance

Teflon is a fluoropolymer, meaning its molecular structure is built on an incredibly strong bond between carbon and fluorine atoms. This bond is exceptionally stable and non-reactive.

This powerful chemical foundation is why Teflon is almost completely inert. It will not corrode, rust, or react with the vast majority of chemicals, including aggressive acids and bases.

What This Means in Practice

In industrial settings, this allows Teflon to be used for seals, gaskets, and linings that handle highly corrosive materials without degrading. The only known substances that can chemically attack it are some molten alkali metals and highly reactive fluorinating agents.

Extreme Thermal Stability

Performance at High and Low Temperatures

Teflon maintains its properties across an exceptionally broad temperature range. It is reliable in cryogenic conditions and can continuously operate at high temperatures, with a melting point around 327°C (600 K).

This stability ensures that components made from Teflon do not become brittle in the cold or degrade when exposed to significant heat, a critical feature for aerospace and industrial processing applications.

Inherent Non-Flammability

Beyond its thermal stability, Teflon is also non-flammable. It will not ignite or promote the spread of fire, which adds a significant layer of safety in any application where it is used.

The "Non-Stick" Phenomenon: Low Friction

One of the Lowest Coefficients of Friction

Teflon possesses one of the lowest coefficients of friction of any known solid material. This means that other substances slide off its surface with extreme ease.

This is the property most famous for its use in non-stick cookware, but its industrial value is far greater.

Beyond the Kitchen

In mechanical applications, this low-friction surface is ideal for bearings, seals, and other parts where minimizing wear and reducing energy loss is critical. It allows components to move smoothly against each other without the need for liquid lubricants.

Superior Electrical Insulation

High Dielectric Strength

Dielectric strength is a measure of a material's ability to act as an electrical insulator. Teflon has a very high dielectric strength, meaning it can withstand high voltages without allowing an electrical current to pass through.

This property, combined with its resistance to heat and moisture, makes it a premier insulating material for high-performance wires, cables, and electronic components.

Understanding the Trade-offs

Low Mechanical Strength

The primary limitation of pure Teflon is its relative softness. It is not a structurally rigid plastic and can deform under a sustained load, a phenomenon known as "creep."

This means it is unsuitable for applications that require high load-bearing capacity without being reinforced or supported by other materials.

Susceptibility to Abrasion

Because it is a soft material, Teflon is prone to scratching and abrasion. This is why metal utensils damage non-stick pan coatings and why it may not be suitable for high-wear environments where it is exposed to abrasive particles.

Making the Right Choice for Your Application

Understanding these properties allows you to deploy Teflon where its unique strengths provide a clear advantage.

- If your primary focus is resisting harsh chemicals or extreme temperatures: Teflon is an elite choice for seals, linings, and components in corrosive or high-heat environments.

- If your primary focus is creating low-friction, non-stick surfaces: Teflon is the benchmark material for applications ranging from cookware to self-lubricating industrial parts.

- If your primary focus is electrical insulation: Its high dielectric strength and thermal stability make it ideal for critical wiring and electronics.

- If your primary focus is high mechanical strength or abrasion resistance: You should consider either a reinforced grade of Teflon or a different material entirely.

Knowing both the profound capabilities and the distinct limitations of Teflon is the key to leveraging its power effectively in your project.

Summary Table:

| Key Property | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals, acids, and bases | Seals, gaskets, liners in corrosive environments |

| Thermal Stability | Performs from cryogenic temps to 327°C (600 K) | High-heat processing, aerospace, and cryogenic applications |

| Low Coefficient of Friction | Creates a near-frictionless, non-stick surface | Non-stick coatings, bearings, self-lubricating parts |

| High Electrical Resistance | Excellent insulator with high dielectric strength | High-performance wiring, cables, and electronic components |

| Limitation: Low Mechanical Strength | Can deform under sustained load (creep) | Requires support or reinforcement for structural parts |

| Limitation: Susceptibility to Abrasion | Prone to scratching and wear | Not ideal for high-wear environments with abrasive particles |

Leverage the Power of Teflon (PTFE) with KINTEK

Do you need high-performance components that demand exceptional chemical resistance, thermal stability, or non-stick properties? The unique synergy of Teflon's properties makes it a powerhouse for specialized industries.

At KINTEK, we manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with precision production to deliver custom fabrication from prototypes to high-volume orders.

Let us help you solve your most challenging application problems. Contact our engineering team today to discuss your specific requirements and get a quote!

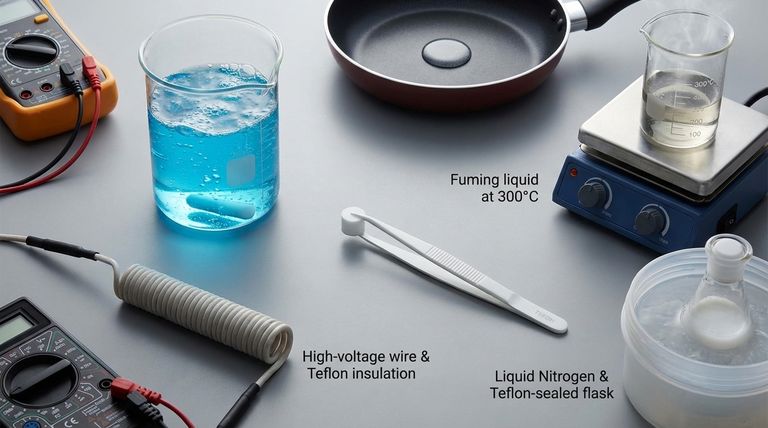

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech