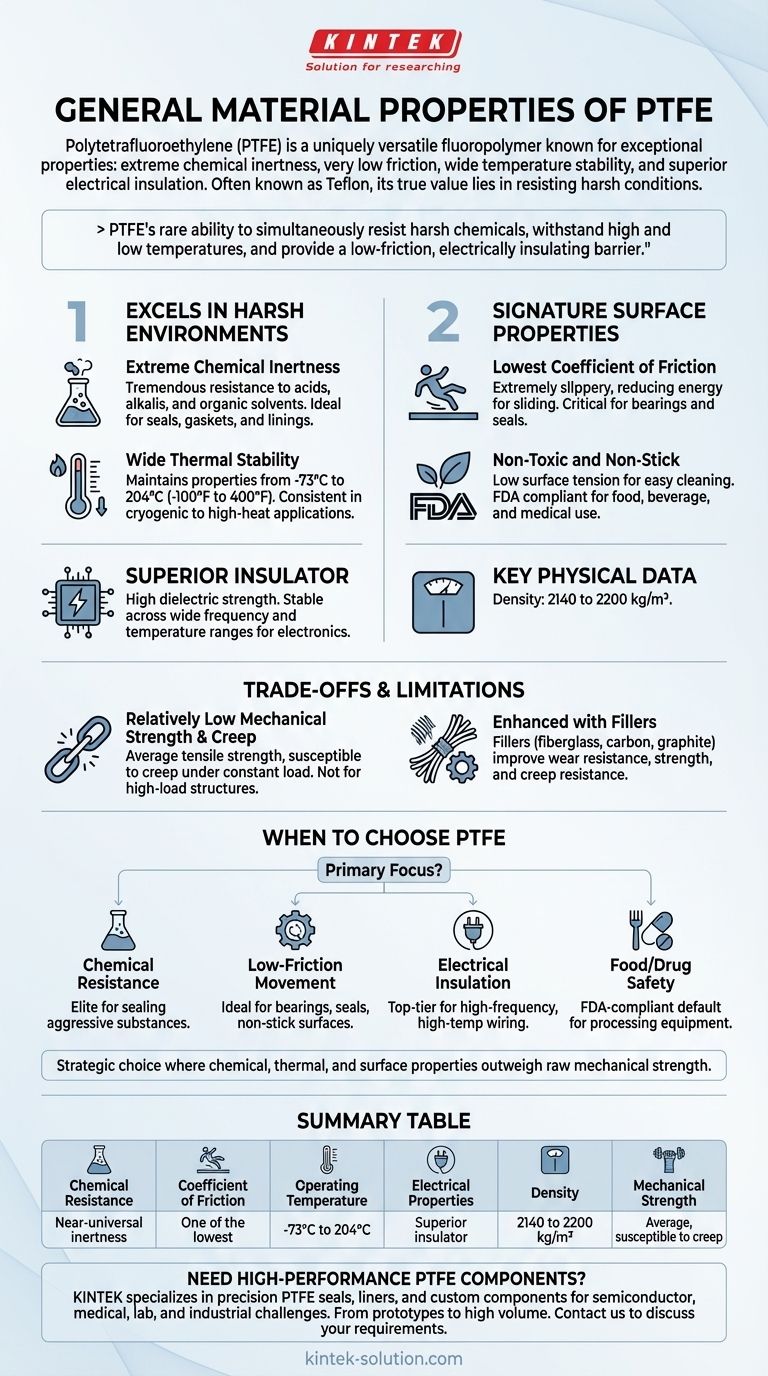

In short, Polytetrafluoroethylene (PTFE) is a uniquely versatile fluoropolymer known for an exceptional combination of properties. Its defining characteristics are extreme chemical inertness, a very low coefficient of friction creating a non-stick surface, and excellent stability across a wide range of temperatures. It also serves as a superior electrical insulator.

While often recognized by its brand name Teflon, PTFE's true value in technical applications comes from its rare ability to simultaneously resist harsh chemicals, withstand high and low temperatures, and provide a low-friction, electrically insulating barrier.

Why PTFE Excels in Harsh Environments

The primary advantage of PTFE is its remarkable resilience. It performs reliably in conditions where many other materials would quickly fail.

Extreme Chemical Inertness

PTFE has tremendous resistance to a vast spectrum of chemicals. This includes aggressive substances like strong acids, alkalis, and organic solvents.

This near-universal inertness makes it an ideal material for seals, gaskets, and linings in chemical processing, pharmaceutical, and laboratory applications.

Wide Thermal Stability

The material maintains its properties across a broad operating temperature range, typically from -73°C to 204°C (-100°F to 400°F).

This allows it to be used in both cryogenic applications and high-heat environments without significant degradation, providing consistent performance.

Understanding its Signature Surface Properties

PTFE's surface is one of its most well-known features, offering benefits beyond just being non-stick.

The Lowest Coefficient of Friction

PTFE boasts one of the lowest coefficients of friction of any solid material. This makes it extremely "slippery," reducing the energy needed for sliding motion.

This property is critical for applications like low-friction bearings, valve components, and seals where minimizing wear and operational force is essential.

Non-Toxic and Non-Stick

Its low surface tension creates a non-stick surface that is easy to clean. Coupled with its chemical inertness, PTFE is naturally non-toxic and meets FDA standards.

This makes it a popular and safe choice for equipment used in the food, beverage, and medical industries.

Performance as an Insulator

Beyond its physical and chemical resilience, PTFE is also an outstanding insulator for both electrical and thermal energy.

Superior Electrical Insulation

PTFE is an exceptional electrical insulator with high dielectric strength that remains stable across wide frequency and temperature ranges.

This makes it invaluable for high-frequency electronics, cable insulation, and other demanding electrical applications.

Key Physical Data

The density of PTFE is relatively high for a plastic, generally ranging from 2140 to 2200 kg/m³ (0.0773 to 0.0795 lb/in³).

Understanding the Trade-offs and Limitations

No material is perfect, and PTFE's unique strengths come with specific mechanical weaknesses that are critical to understand.

Relatively Low Mechanical Strength

Compared to engineering plastics like nylon or PEEK, pure PTFE has only average tensile strength and is relatively soft. It is not suitable for high-load structural applications on its own.

Susceptibility to Creep

PTFE is a pliable material that can deform or "creep" over time when subjected to a constant compressive load. This must be factored into the design of seals and gaskets.

The Role of Fillers

To counteract its mechanical weaknesses, PTFE is often enhanced with fillers like fiberglass, carbon, or graphite. These additives significantly improve its wear resistance, strength, and resistance to creep while retaining its other key properties.

When to Choose PTFE for Your Application

Selecting the right material requires aligning its properties with your primary goal.

- If your primary focus is chemical resistance: PTFE is an elite choice for sealing or containing virtually any aggressive acid, solvent, or alkali.

- If your primary focus is low-friction movement: It is ideal for creating non-lubricated bearings, sliding plates, seals, or non-stick surfaces.

- If your primary focus is electrical insulation: PTFE is a top-tier material for high-frequency and high-temperature wiring, connectors, and circuit boards.

- If your primary focus is food or drug safety: Its non-toxic, FDA-compliant nature makes it a default choice for processing and packaging equipment.

Ultimately, selecting PTFE is a strategic choice for applications where its chemical, thermal, and surface properties are more critical than its raw mechanical strength.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Chemical Resistance | Near-universal inertness to acids, alkalis, and solvents |

| Coefficient of Friction | One of the lowest of any solid material |

| Operating Temperature | Stable from -73°C to 204°C (-100°F to 400°F) |

| Electrical Properties | Superior insulator with high dielectric strength |

| Density | 2140 to 2200 kg/m³ |

| Mechanical Strength | Average tensile strength; susceptible to creep under load |

Need high-performance PTFE components for your application?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components. We leverage PTFE's exceptional properties to solve complex challenges in the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get parts that deliver superior chemical resistance, low friction, and reliable insulation exactly where you need it.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the different types of Teflon available? A Guide to PTFE, FEP, PFA, and More

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- How does PTFE contribute to environmental benefits? Durability, Efficiency, and Contamination Prevention

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers