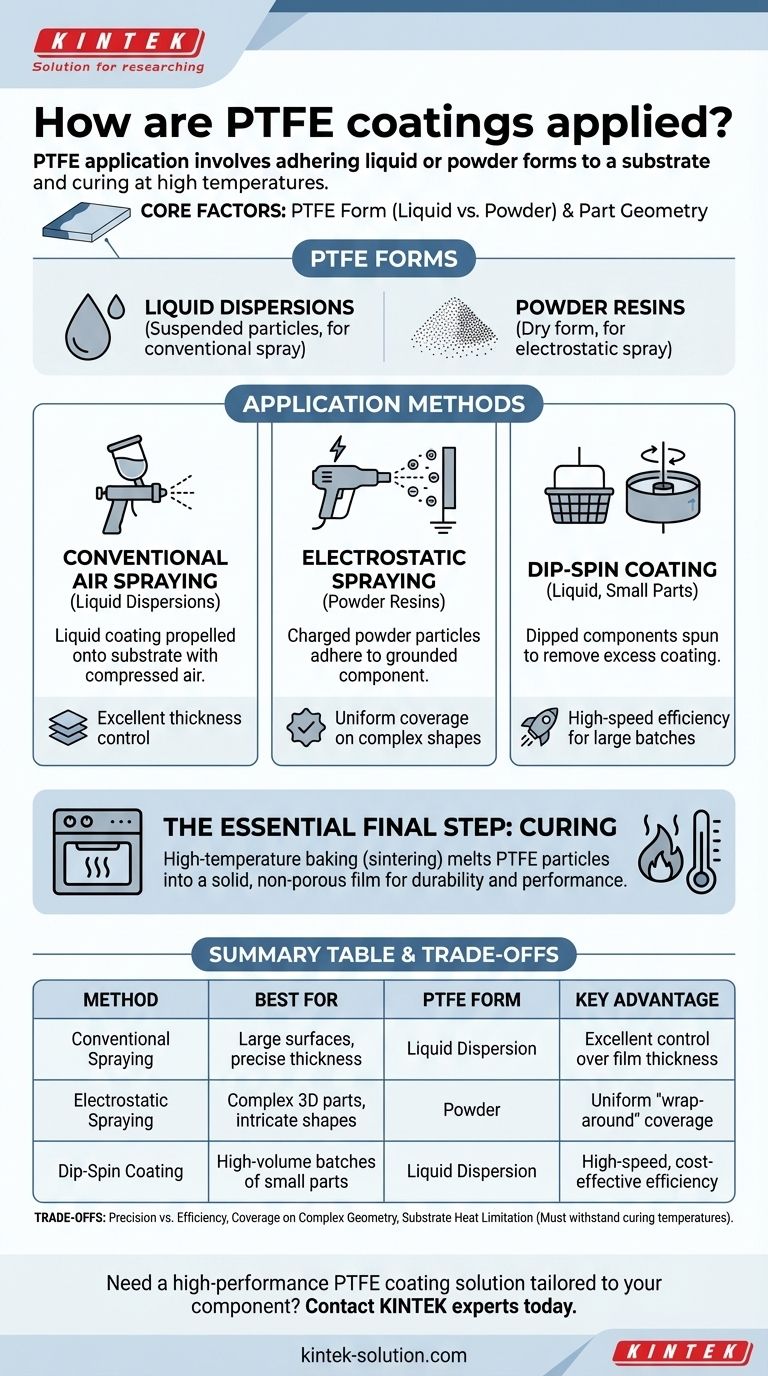

At its core, applying a Polytetrafluoroethylene (PTFE) coating involves adhering the material in its liquid or powder form to a substrate and then curing it at high temperatures. The primary industrial methods are conventional spraying for liquid dispersions, electrostatic spraying for powders, and dip-spinning for small components. Each technique culminates in a heat treatment process that fuses the PTFE into a solid, functional film.

The specific application method for a PTFE coating is not a matter of preference but is dictated by two key factors: the physical form of the raw PTFE (liquid vs. powder) and the geometry of the part being coated.

The Foundation: Understanding PTFE Forms

Before a coating can be applied, its raw material form must be considered. PTFE is not a universal substance; it is processed into distinct forms for different application needs.

Liquid Dispersions

Most commonly, PTFE is supplied as a liquid dispersion. In this form, fine PTFE particles are suspended in water or another liquid carrier. This consistency makes it suitable for application with conventional spray equipment, much like applying paint.

Powder Resins

PTFE and related fluoropolymers like FEP and PFA can also be processed into a fine powder. This dry form cannot be applied with traditional sprayers and requires a specialized technique to adhere to a surface before baking.

Core Application Methods Explained

The choice between liquid and powder directly informs the application strategy. Each method is tailored to efficiently and evenly coat a component before the final curing stage.

Conventional Air Spraying

For liquid PTFE dispersions, the most common application method is conventional spraying. The liquid coating is loaded into gravity-fed or pressure-fed spray equipment and propelled onto the substrate using compressed air. This technique offers excellent control over the thickness of the final coating.

Electrostatic Spraying

This method is designed for powdered fluoropolymers. An electrode in the spray gun imparts a negative electrical charge to the powder particles as they exit the nozzle. The component to be coated is grounded, giving it a positive charge. The opposing charges create an attraction, pulling the powder onto the part and causing it to adhere evenly, even on complex shapes.

Dip-Spin Coating

When dealing with large quantities of small parts, such as fasteners or clips, dip-spin coating is the most efficient method. Components are placed in a basket, dipped into a tank of liquid PTFE, and then spun at high speed to remove the excess coating through centrifugal force.

The Essential Final Step: Curing

No matter the application method, the coating is not functional until it is cured. This is arguably the most critical phase of the entire process.

What is Curing?

Curing involves baking the coated component in an industrial oven at very high temperatures. This heat causes the individual PTFE particles to melt and flow together.

Why Curing is Critical

This melting and flowing action, sometimes called sintering, is what forms the solid, non-porous film that gives the surface its non-stick and chemical-resistant properties. Without proper curing, the coating would remain a layer of disconnected particles with no durability or protective function.

Understanding the Trade-offs

Each application method comes with its own set of advantages and limitations that make it suitable for different scenarios.

Precision vs. Efficiency

Conventional spraying offers the highest degree of control over film thickness, which is critical for many technical applications. Dip-spinning, conversely, sacrifices some of this precision for the high-volume efficiency needed to process thousands of small parts cost-effectively.

Coverage on Complex Geometry

For parts with intricate shapes, holes, and corners, electrostatic spraying is superior. The electrical attraction creates a "wrap-around" effect, ensuring powder reaches and adheres to areas that would be difficult to cover evenly with a direct line-of-sight spray.

The Substrate Heat Limitation

The single biggest constraint for all PTFE coatings is the high-temperature curing cycle. The part being coated must be able to withstand these temperatures without deforming or melting. This is why PTFE is almost always applied to metals and is generally unsuitable for most plastics or wood.

Making the Right Choice for Your Goal

Selecting the correct application process is essential to leverage PTFE's unique benefits for improved performance, safety, and efficiency in everything from non-stick cookware to advanced medical devices.

- If your primary focus is uniform coverage on complex 3D parts: Electrostatic spraying of a powder coating is the most reliable method.

- If your primary focus is precise thickness control on large surfaces: Conventional air-spraying with a liquid dispersion offers the best results.

- If your primary focus is cost-effective coating for large batches of small items: Dip-spin coating provides unparalleled speed and efficiency.

Ultimately, the right application technique ensures the unique properties of PTFE are fully realized, transforming a simple surface into a high-performance component.

Summary Table:

| Method | Best For | PTFE Form | Key Advantage |

|---|---|---|---|

| Conventional Spraying | Large surfaces, precise thickness | Liquid Dispersion | Excellent control over film thickness |

| Electrostatic Spraying | Complex 3D parts, intricate shapes | Powder | Uniform "wrap-around" coverage |

| Dip-Spin Coating | High-volume batches of small parts | Liquid Dispersion | High-speed, cost-effective efficiency |

Need a high-performance PTFE coating solution tailored to your component's geometry and volume?

At KINTEK, we specialize in the precision manufacturing and custom fabrication of PTFE components, including expert coating services. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your parts achieve optimal non-stick, chemical resistance, and durability.

Contact our experts today to discuss your project and leverage the right PTFE application method for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the applications of PTFE laminated fabric in special apparel? A Guide to Advanced Protection & Comfort

- What are the limitations of PTFE? Understanding Creep, Abrasion, and Radiation Weaknesses

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- How is PTFE applied in the electrical and electronics industries? Unlock High-Performance Insulation

- How does PTFE benefit aerospace applications? Achieve Superior Performance in Extreme Environments

- What are the main advantages of using PTFE in manufacturing? Boost Efficiency & Durability

- What are the applications of stainless steel-filled PTFE? Achieve Superior Strength and Chemical Resistance