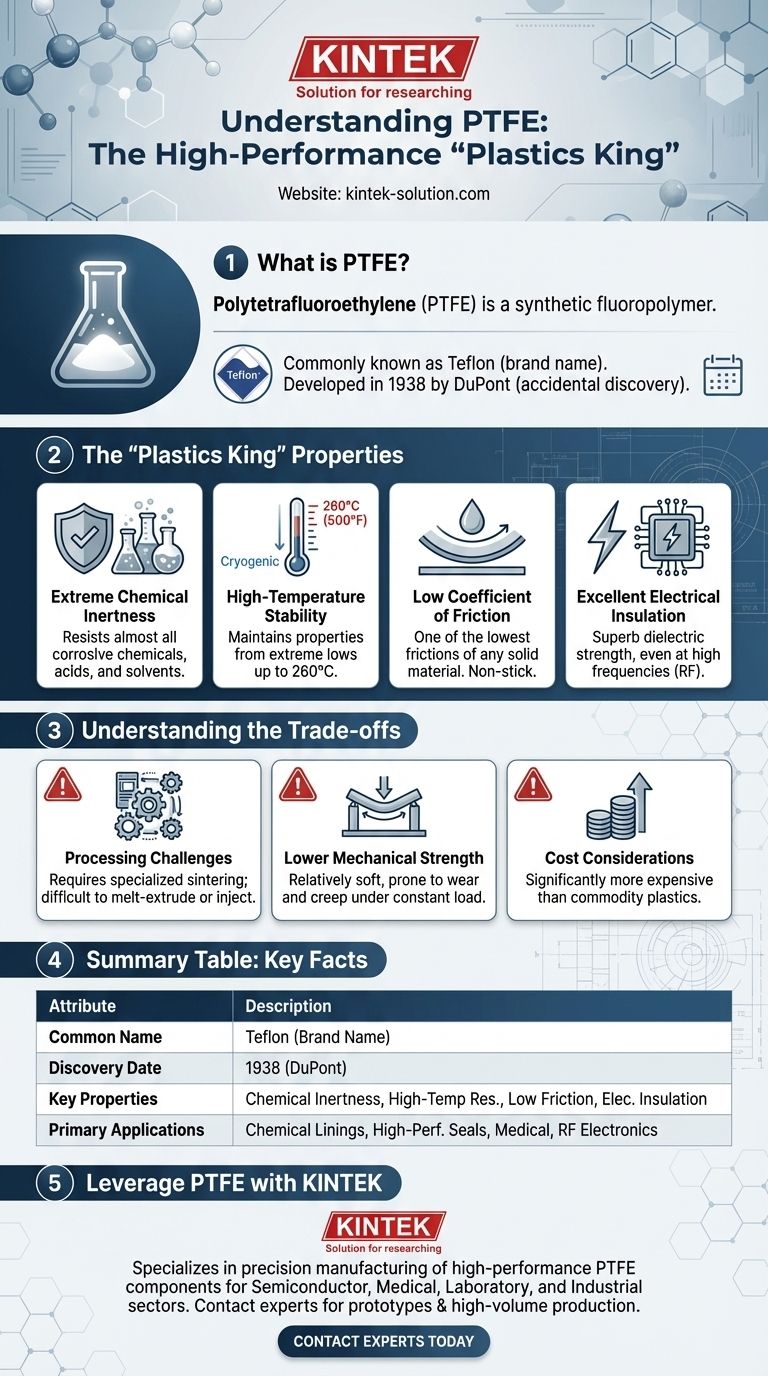

In short, Polytetrafluoroethylene (PTFE) is most famously known by the brand name Teflon. This high-performance polymer, often nicknamed the "plastics king," was first discovered accidentally in 1938 by a scientist at DuPont.

While widely recognized for creating non-stick pans, PTFE's true significance lies in its extreme chemical and thermal resistance. This makes it an indispensable material in demanding industrial, medical, and electronic applications where other plastics would fail.

What Exactly is PTFE?

PTFE is a synthetic fluoropolymer, a type of high-performance plastic. Its discovery and subsequent development marked a significant milestone in materials science.

A Serendipitous Discovery

PTFE was discovered in 1938 at a DuPont research laboratory. A chemist was working with refrigerant gases and found that a pressurized bottle of tetrafluoroethylene gas had polymerized into a strange, waxy white solid. This new substance proved to have remarkable properties.

The Chemical Backbone: Carbon and Fluorine

PTFE is a polymer made of only two elements: carbon and fluorine. The bond between carbon and fluorine atoms is exceptionally strong and stable. This powerful chemical bond is the source of PTFE's most valuable characteristics.

PTFE vs. Teflon: Understanding the Terms

It is crucial to understand that PTFE is the name of the material itself. Teflon is simply the most well-known brand name for PTFE, commercialized by the DuPont company and now by its spin-off, Chemours.

The Properties That Define the "Plastics King"

PTFE earned its "plastics king" nickname not because of its use in cookware, but because of its unparalleled performance in harsh environments where other materials degrade.

Extreme Chemical Inertness

Because of its strong carbon-fluorine bonds, PTFE is almost completely inert. It does not react with the vast majority of corrosive acids, bases, and solvents, making it ideal for lining chemical reactors, pipes, and vessels.

High-Temperature Stability

PTFE can withstand a very wide range of temperatures, maintaining its properties from cryogenic lows up to around 260°C (500°F). This makes it a reliable choice for high-heat industrial processes.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This "slipperiness" is what makes it an excellent non-stick coating, but it is also used for low-friction bearings, seals, and other mechanical parts that require smooth movement.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with a high dielectric strength, even at high radio frequencies (RF). This property makes it a material of choice for high-performance wiring, coaxial cables, and printed circuit boards (PCBs) used in RF systems.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE offers exceptional performance, it comes with specific trade-offs that are critical to understand for any engineering application.

Processing Challenges

Unlike common thermoplastics like polyethylene or polypropylene, PTFE cannot be easily processed using conventional melt-extrusion or injection molding techniques. It requires specialized methods like sintering, which can increase manufacturing complexity and cost.

Lower Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has poor resistance to wear and "creep" (the tendency to slowly deform under a constant load). Its structural integrity is not its primary strength.

Cost Considerations

As a high-performance fluoropolymer, PTFE is significantly more expensive than commodity plastics. Its use must be justified by a clear need for its unique properties.

When to Choose PTFE for Your Application

Selecting PTFE depends entirely on whether its unique benefits justify its specific trade-offs for your goal.

- If your primary focus is extreme chemical or thermal resistance: PTFE is an unparalleled choice for seals, gaskets, and linings in aggressive chemical and high-temperature environments.

- If your primary focus is low friction and non-stick surfaces: PTFE remains the benchmark material for coatings, self-lubricating bearings, and medical devices where lubricity is critical.

- If your primary focus is cost-sensitive, high-strength structural parts: You should evaluate other engineering plastics, as PTFE's lower mechanical strength and higher cost may not be optimal for these applications.

Understanding PTFE moves you from simply recognizing a brand name to strategically leveraging a powerful engineering material.

Summary Table:

| Key Attribute | Description |

|---|---|

| Common Name | Teflon (a brand name for PTFE) |

| Discovery Date | 1938 (by a DuPont chemist) |

| Key Properties | Extreme chemical inertness, high-temperature resistance (up to 260°C/500°F), very low friction, excellent electrical insulation |

| Primary Applications | Chemical processing linings, high-performance seals, non-stick coatings, medical devices, high-frequency electronics |

Leverage the power of PTFE for your most demanding applications. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards of chemical and thermal resistance. Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the advantages of polyamide fillers in PTFE? Protect Soft Mating Surfaces with Non-Abrasive Performance

- What are the advantages of PTFE over Polyethylene Terephthalate (PET)? Key Benefits for Demanding Applications

- What temperature range can Teflon plastic sheets withstand? Unlocking Performance from -200°C to +260°C

- What are the benefits of Teflon's softness? Unlock Superior Flexibility and Low-Friction Performance

- What are the two common forms in which PTFE is available? Raw Resins vs. Semi-Finished Shapes

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- What is PTFE and what are its common uses in industrial applications? Discover the Ultimate High-Performance Polymer

- What are the primary properties of Teflon that make it a 'powerhouse plastic'? Unlock Unmatched Performance