In pulp and paper manufacturing, Teflon bellow mechanical seals are critical components used in equipment like pulp digesters, paper machine rollers, various pumps, and wastewater treatment systems. Their widespread application stems from an exceptional ability to provide reliable sealing in environments defined by harsh chemicals, high temperatures, and abrasive materials, which would cause conventional seals to fail.

The core value of a Teflon bellow seal in a pulp mill is not simply stopping a leak. It is about providing a durable, flexible sealing solution that withstands the industry's most corrosive and abrasive processes, directly reducing equipment downtime and ensuring environmental compliance.

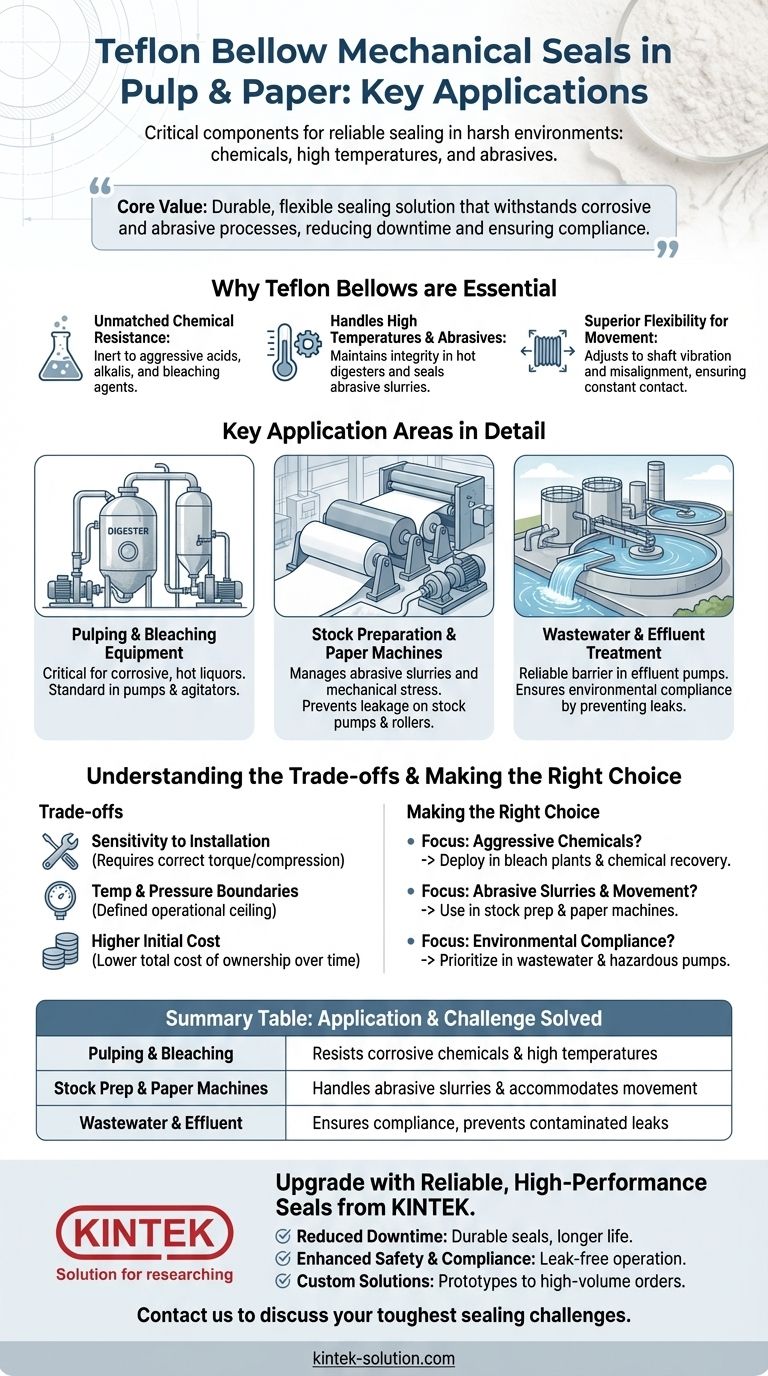

Why Teflon Bellows are Essential in Pulp & Paper

The pulp and paper industry presents a uniquely punishing environment for mechanical components. Teflon (PTFE) bellow seals are specifically engineered to thrive under these conditions where other materials cannot.

Unmatched Chemical Resistance

The process of turning wood into paper involves aggressive chemicals, including strong acids and alkalis used in pulping and bleaching.

PTFE is almost entirely chemically inert. This property ensures the seal will not degrade, swell, or weaken when exposed to corrosive media like white, green, or black liquor, or various bleaching agents.

Accommodating High Temperatures and Abrasives

Pulping processes, especially in digesters, operate at high temperatures. Furthermore, the pulp slurry itself is an abrasive mixture of fibers and liquid.

Teflon maintains its integrity at the high temperatures found in pulp digestion. The bellow design, combined with durable face materials, effectively seals abrasive slurries in pumps, mixers, and agitators, preventing premature wear and leakage.

Superior Flexibility for Mechanical Movement

Pulp and paper machinery, such as large paper machine rollers and mixers, often involves significant shaft vibration, radial movement, or minor misalignment.

The flexible "bellow" construction of the seal allows it to dynamically adjust to these movements. This ensures the seal faces remain in constant contact, maintaining a tight seal where a more rigid seal would fail.

Key Application Areas in Detail

Teflon bellow seals are deployed strategically in the most demanding stages of the manufacturing process to maximize operational reliability.

Pulping and Bleaching Equipment

This is where the chemical and thermal resistance of PTFE is most critical. These seals are standard in pumps and agitators that handle the highly corrosive and hot liquors used to break down wood fibers and bleach the pulp.

Stock Preparation and Paper Machines

In this stage, the challenge shifts to managing abrasive pulp slurries and mechanical stress. Teflon bellow seals are used in stock pumps, agitators, and on the ends of large paper machine rollers.

Their ability to handle both abrasive media and shaft misalignment prevents stock leakage and protects sensitive bearing assemblies, reducing costly unplanned maintenance.

Wastewater and Effluent Treatment

Every pulp and paper mill operates a comprehensive wastewater treatment system. The liquids here can be contaminated, corrosive, and subject to strict environmental regulations.

Using Teflon bellow seals in effluent pumps and mixers provides a reliable barrier, preventing the leakage of contaminated water and chemicals. This is essential for maintaining environmental compliance and protecting surrounding ecosystems.

Understanding the Trade-offs

While highly effective, Teflon bellow seals are not a universal solution. Acknowledging their limitations is key to proper application.

Sensitivity to Installation

The performance of a PTFE bellow seal is highly dependent on correct installation. Because PTFE can exhibit "cold flow" or creep over time, improper compression or uneven bolt torque can lead to a gradual loss of seal integrity.

Temperature and Pressure Boundaries

While excellent in many high-temperature applications, PTFE has a defined operational ceiling. In processes with simultaneous very high pressure and very high temperature, the material can be prone to extrusion or deformation. Careful engineering review is necessary for these extreme edge cases.

Higher Initial Cost

Specialized components like Teflon bellow seals typically carry a higher upfront cost compared to simpler elastomeric seals. This initial investment is justified by a lower total cost of ownership, achieved through significantly longer service life, reduced maintenance labor, and minimized production loss from downtime.

Making the Right Choice for Your Goal

The decision to use a Teflon bellow seal should be driven by the specific challenge you need to solve within your process.

- If your primary focus is handling aggressive chemicals: Deploy these seals in bleach plants, chemical recovery areas, and dosing pumps where any other seal material would rapidly degrade.

- If your primary focus is managing abrasive slurries and shaft movement: Use them in stock preparation pumps, agitators, and on paper machine rollers to significantly extend maintenance intervals and prevent wear.

- If your primary focus is environmental compliance and safety: Prioritize their use in all wastewater, effluent, and hazardous chemical pumps to guarantee leak-free operation and avoid regulatory issues.

Ultimately, deploying Teflon bellow seals strategically is a direct investment in the long-term reliability and efficiency of your plant's most critical equipment.

Summary Table:

| Application Area | Key Challenge Solved by Teflon Bellow Seal |

|---|---|

| Pulping & Bleaching Equipment | Resists corrosive chemicals (e.g., white liquor, bleaching agents) and high temperatures |

| Stock Preparation & Paper Machines | Handles abrasive pulp slurries and accommodates shaft misalignment/vibration |

| Wastewater & Effluent Treatment | Ensures environmental compliance by preventing leaks of contaminated fluids |

Upgrade your pulp and paper equipment with reliable, high-performance seals from KINTEK.

Our precision-manufactured PTFE components, including custom bellow seals, are engineered to withstand the industry's most demanding conditions—from aggressive chemicals in digesters to abrasive slurries in paper machines. By choosing KINTEK, you benefit from:

- Reduced Downtime: Durable seals that last longer, minimizing unplanned maintenance.

- Enhanced Safety & Compliance: Leak-free operation protects your workforce and environment.

- Custom Solutions: We fabricate prototypes to high-volume orders tailored to your specific equipment and process needs.

Contact us today at [#ContactForm] to discuss how our PTFE seals can solve your toughest sealing challenges and boost your plant's efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What role do ceramic fillers play in PTFE laminates? Enhance Signal Integrity & Thermal Performance

- Why is ePTFE suitable for aerospace applications? Achieve Lightweight Reliability in Extreme Conditions

- Why are PTFE spring-energized seals preferred for dynamic sealing applications? For Superior, Long-Lasting Performance

- What are the key benefits of PTFE rotary shaft seals in high-performance machinery? Maximize Uptime & Efficiency

- What types of PTFE machined parts are commonly produced? Essential Components for Demanding Industries

- What are important installation tips for PTFE butterfly valves? Ensure a Leak-Free, Long-Lasting Seal

- Which type of seal is best suited for high-speed applications? PTFE Seals for Speeds Up to 35 m/s

- In which industries or applications are Teflon (PTFE) balls commonly used? Essential for Harsh Environments