In dynamic sealing, performance is a function of endurance. PTFE spring-energized seals are preferred for these applications because they combine the exceptionally low friction and wide operational range of PTFE with the consistent, mechanical force of a spring energizer. This unique pairing creates a highly reliable seal that actively compensates for wear, temperature changes, and pressure fluctuations.

The true advantage of a PTFE spring-energized seal isn't just the material, but the system. The spring provides a constant, resilient force that the PTFE jacket alone cannot, ensuring a leak-free seal in dynamic applications where conditions are rarely stable.

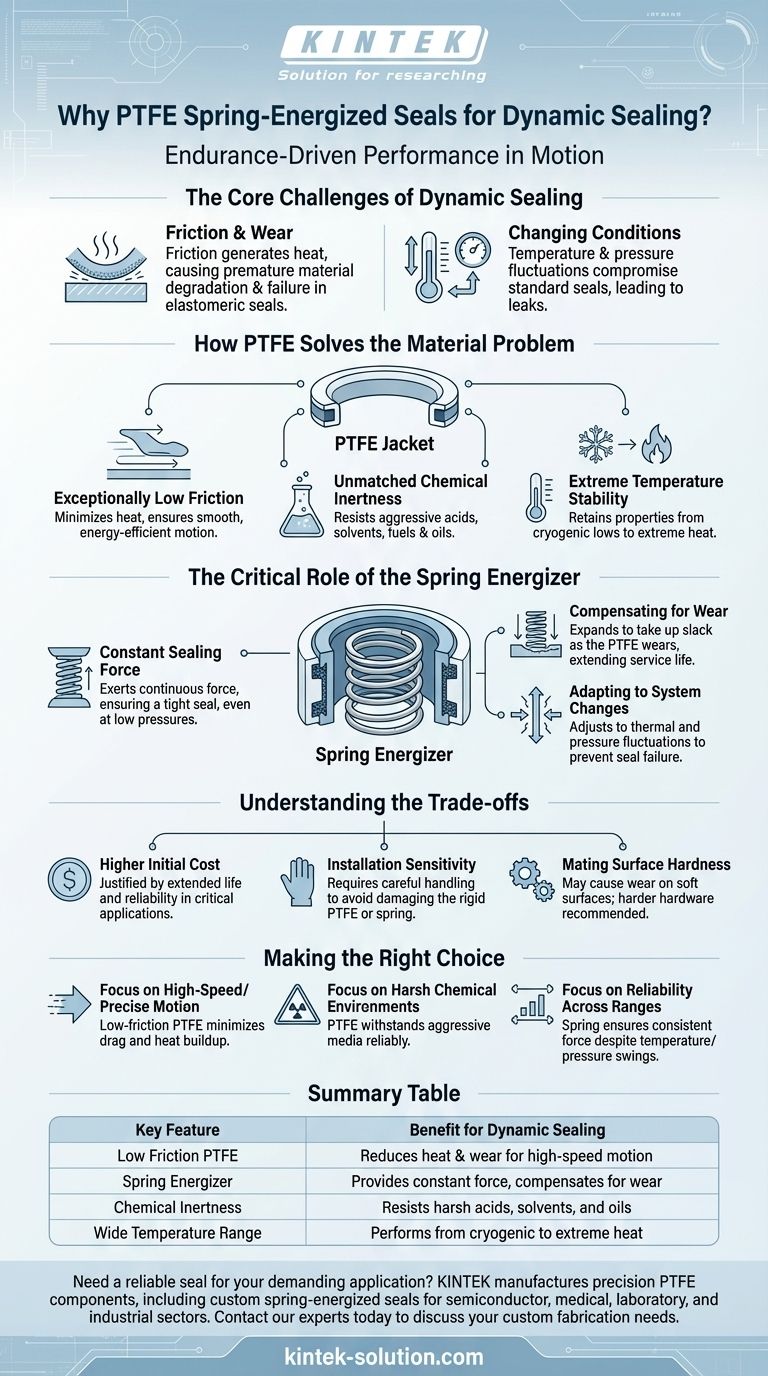

The Core Challenges of Dynamic Sealing

Dynamic seals operate where parts are in motion relative to each other, such as in pistons, actuators, or rotating shafts. This movement introduces challenges that static seals don't face.

The Problem of Friction and Wear

In any moving system, friction generates heat and causes material wear. Traditional elastomeric (rubber) seals can degrade quickly under high-speed movement, leading to premature failure.

The Problem of Changing Conditions

Real-world systems rarely operate at a constant temperature or pressure. These fluctuations cause materials to expand or contract, which can compromise the integrity of a standard seal and lead to leaks.

How PTFE Solves the Material Problem

The seal jacket is made from Polytetrafluoroethylene (PTFE), a material with a unique combination of properties perfectly suited for demanding environments.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is critical for dynamic applications, as it minimizes heat generation and allows for smooth, precise motion with less energy consumption.

Unmatched Chemical Inertness

PTFE is virtually inert to most industrial chemicals, including aggressive acids, solvents, fuels, and oils. This ensures the seal will not degrade or swell when exposed to harsh media.

Extreme Temperature Stability

The material retains its mechanical properties and sealing characteristics across an enormous temperature range, from cryogenic lows to extreme heat. This stability prevents the seal from becoming brittle in the cold or soft in the heat.

The Critical Role of the Spring Energizer

While PTFE provides the ideal material properties, it is not highly elastic like rubber. The internal spring is the engine of the seal, providing the "live" energy required for a persistent, reliable seal.

Providing Constant Sealing Force

The spring exerts a continuous, uniform force, pressing the PTFE lips against the sealing surfaces. This ensures a tight seal even in low-pressure conditions where system pressure alone isn't enough to actuate the seal.

Compensating for Wear

As the PTFE seal jacket slowly wears down over millions of cycles, the spring continues to expand. This action takes up the slack created by wear, dramatically extending the effective service life of the seal.

Adapting to System Changes

The spring actively adjusts to thermal expansion and contraction of both the seal and the hardware. This ensures the seal lips remain engaged and effective despite temperature swings or pressure spikes that would cause other seal types to fail.

Understanding the Trade-offs

While highly effective, PTFE spring-energized seals are an engineered solution with specific considerations.

Higher Initial Cost

These are high-performance components and are typically more expensive than standard elastomeric O-rings or U-cups. Their cost is justified by their extended life and reliability in critical applications.

Installation Sensitivity

The relative rigidity of the PTFE jacket and the presence of the spring make installation more delicate than with a simple rubber seal. Care must be taken to avoid scratching the seal lips or damaging the spring.

Mating Surface Hardness

The constant, concentrated force from the spring can cause wear on softer mating surfaces (like aluminum or brass) over time. Harder, wear-resistant hardware surfaces are generally recommended for optimal performance.

Making the Right Choice for Your Application

Choosing the right seal depends entirely on the operational demands of your system.

- If your primary focus is high-speed or precise motion: The low-friction properties of PTFE spring-energized seals are essential for minimizing drag and heat buildup.

- If your primary focus is sealing in harsh chemical environments: The chemical inertness of PTFE makes it one of the few materials that can reliably withstand aggressive media.

- If your primary focus is reliability across wide temperature or pressure ranges: The spring energizer ensures a consistent sealing force when other materials would harden, soften, or lose their shape.

Ultimately, PTFE spring-energized seals provide a robust engineering solution for dynamic applications where failure is not an option.

Summary Table:

| Key Feature | Benefit for Dynamic Sealing |

|---|---|

| Low Friction PTFE | Reduces heat & wear for high-speed motion |

| Spring Energizer | Provides constant force, compensates for wear |

| Chemical Inertness | Resists harsh acids, solvents, and oils |

| Wide Temperature Range | Performs from cryogenic to extreme heat |

Need a reliable seal for your demanding application? KINTEK manufactures precision PTFE components, including custom spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals deliver long-lasting, leak-free performance. Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech