The most important installation tips for a PTFE butterfly valve are to perform thorough pre-installation checks, ensure perfect alignment, use correct gasket placement, and follow a strict, cross-pattern bolting sequence with the proper torque. Unlike other materials, the unique properties of PTFE mean that improper installation can easily cause permanent deformation and seal failure.

The central challenge with PTFE butterfly valves is managing the material's tendency to "cold flow" or permanently deform under pressure. A successful installation is less about force and more about precision—ensuring even, correct pressure across the flange to create a lasting seal without damaging the seat.

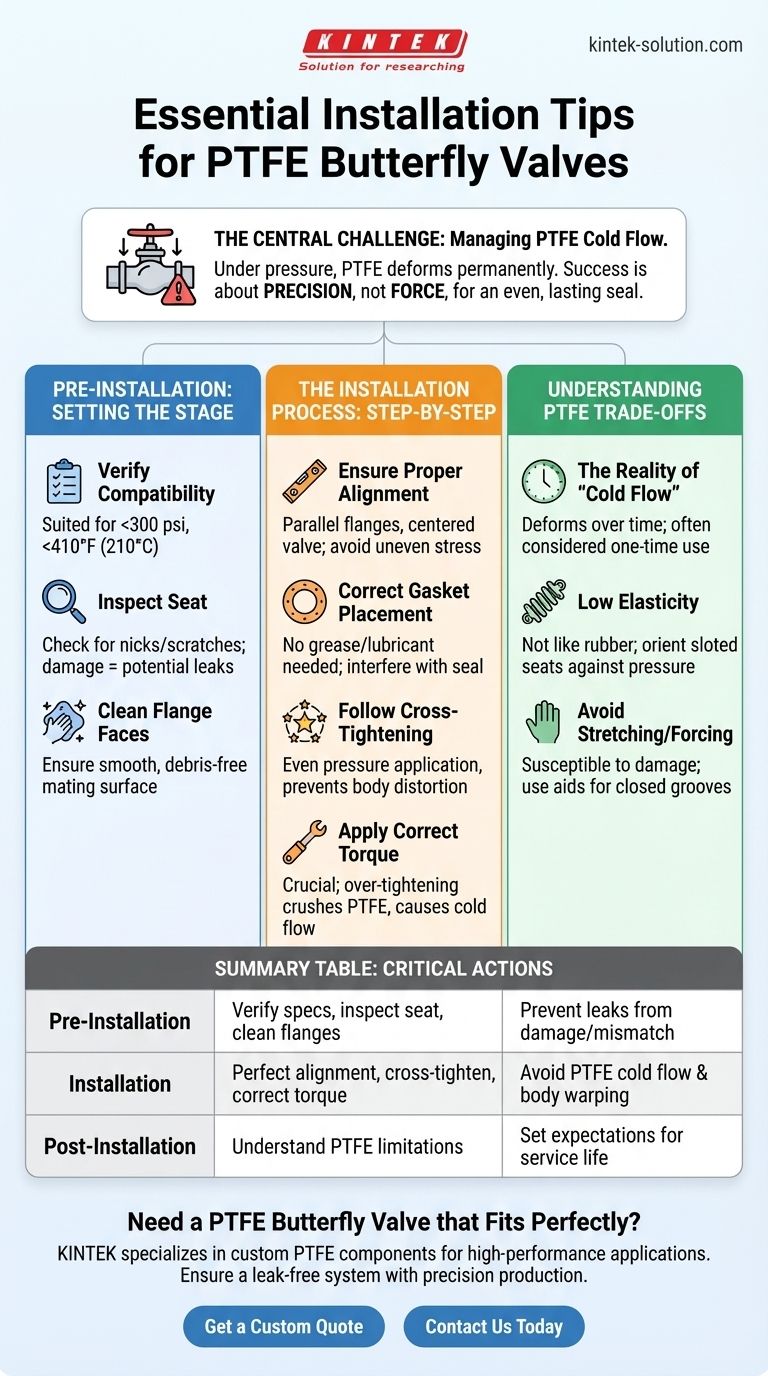

Pre-Installation: Setting the Stage for Success

Before the valve even touches the pipeline, a few critical checks can prevent the most common installation failures. Rushing this stage is a frequent and costly mistake.

Verify Valve and System Compatibility

First, confirm the valve's specifications match the system's operational demands. PTFE-lined valves are typically suited for conditions below 300 psi and 410°F (210°C). Mismatching the valve to the application is a primary cause of premature failure.

Inspect the PTFE Seat

Carefully inspect the valve's PTFE seat and liner for any nicks, scratches, or imperfections from shipping or handling. Any surface damage creates a potential leak path that tightening the bolts cannot fix.

Clean Flange Faces

Ensure the pipe flanges are perfectly clean, dry, and free of any old gasket material, rust, or debris. A smooth, clean mating surface is essential for the PTFE seat to seal correctly.

The Installation Process: A Step-by-Step Guide

The physical installation requires a methodical approach. The goal is to achieve a seal by applying uniform pressure without warping the valve body or deforming the PTFE seat.

Ensure Proper Alignment

Use leveling tools to guarantee the pipe flanges are parallel and the valve is perfectly centered. Misalignment places uneven stress on the valve body and the PTFE seat, leading to leaks and operational issues.

Handle Gaskets and Seating Surfaces Correctly

PTFE's naturally low friction means no grease or lubricant is needed during placement. Adding any compound can interfere with the seal and is unnecessary. Place the valve and any required gaskets carefully between the flanges.

Follow a Cross-Tightening Sequence

Always tighten the flange bolts in a star or cross-pattern sequence. This method ensures pressure is applied evenly across the flange, preventing distortion of the valve body and ensuring the disc can open and close freely.

Apply the Correct Torque

Applying the correct, specified torque is absolutely critical. Over-tightening is the most common installation error and will crush the PTFE seat, causing it to cold flow excessively and leading to a permanent leak.

Understanding the Trade-offs of PTFE

PTFE is an excellent material for its chemical inertness, but its mechanical properties demand specific handling. Understanding these limitations is key to a successful installation.

The Reality of "Cold Flow"

Under compressive stress from the flange bolts, PTFE will slowly deform over time. This "cold flow" is why correct, even torque is so important. It is also why many PTFE-seated valves are considered one-time use; once compressed, the seat takes a permanent set and will likely not reseal properly if removed and reinstalled.

The Limitation of Low Elasticity

PTFE is not as elastic as rubber. To compensate, some designs are slotted. When installing a slotted PTFE seat, you must orient the slot so it faces away from the primary pressure source (against the pressure). This allows the pressure to help seal the valve.

Avoid Stretching or Forcing

Never stretch or force the PTFE seat during installation. Its physical properties make it susceptible to damage from mishandling. If working with closed grooves, use appropriate installation aids to gently guide the seat into place.

How to Apply This to Your Project

Your installation priority will determine which steps require the most attention.

- If your primary focus is preventing leaks: Concentrate on the cross-tightening sequence and applying the exact manufacturer-specified torque to avoid deforming the seat.

- If your primary focus is maximizing valve lifespan: Emphasize perfect initial alignment and avoiding over-tightening, as these actions prevent the uneven stress that accelerates permanent damage from cold flow.

- If you are working with a slotted PTFE design: Your most critical step is to double-check that the slot is oriented against the direction of system pressure to ensure a proper seal.

Ultimately, a precise and methodical installation is the single greatest factor in the performance and longevity of a PTFE butterfly valve.

Summary Table:

| Installation Phase | Critical Action | Key Reason |

|---|---|---|

| Pre-Installation | Verify specs, inspect seat, clean flanges | Prevent leaks from damage/mismatch |

| Installation | Perfect alignment, cross-tighten bolts, apply correct torque | Avoid PTFE cold flow and body warping |

| Post-Installation | Understand PTFE is often one-time use | Set expectations for valve service life |

Need a PTFE Butterfly Valve that Fits Perfectly from the Start?

Proper installation begins with a high-quality, precision-manufactured valve. KINTEK specializes in custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production to ensure your components are easy to install and perform reliably. Whether you need prototypes or high-volume orders, our custom fabrication service delivers the exact fit and performance your application demands.

Contact us today to discuss your specific requirements and ensure a leak-free system: Get a Custom Quote

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are potential issues when machining Teflon? Overcome PTFE's Softness, Slipperiness, and Thermal Instability

- What makes PTFE reliable for sealing applications? Unmatched Chemical & Thermal Stability

- How should PTFE material be supported during machining? Achieve Precision with Minimal Clamping Pressure

- What considerations are important for fixture design when machining PTFE parts? Master Stability Without Distortion

- What are the primary challenges in molding PTFE? Overcome High Melt Viscosity and Sintering Complexities

- What is the advantage of PTFE's self-lubricating properties in shaft seals? Achieve Reliable, Maintenance-Free Performance

- What are the key advantages of using PTFE envelope gaskets? Superior Sealing for Aggressive Chemical & High-Pressure Applications

- How do PTFE sealed ball bearings enhance riding performance? Achieve Faster, Longer-Lasting Speed