The single most important consideration for fixture design when machining PTFE is achieving absolute stability with the absolute minimum clamping pressure. Because Polytetrafluoroethylene (PTFE) is exceptionally soft and has a high rate of thermal expansion, the fixture's primary job is to support the workpiece comprehensively without crushing, distorting, or constraining it as it heats up during the machining process.

Your approach to fixturing PTFE must shift from simple clamping to total support. The goal is not to pin the material down with force, but to create a stable cradle that prevents vibration and deformation from the moment the tool touches the part.

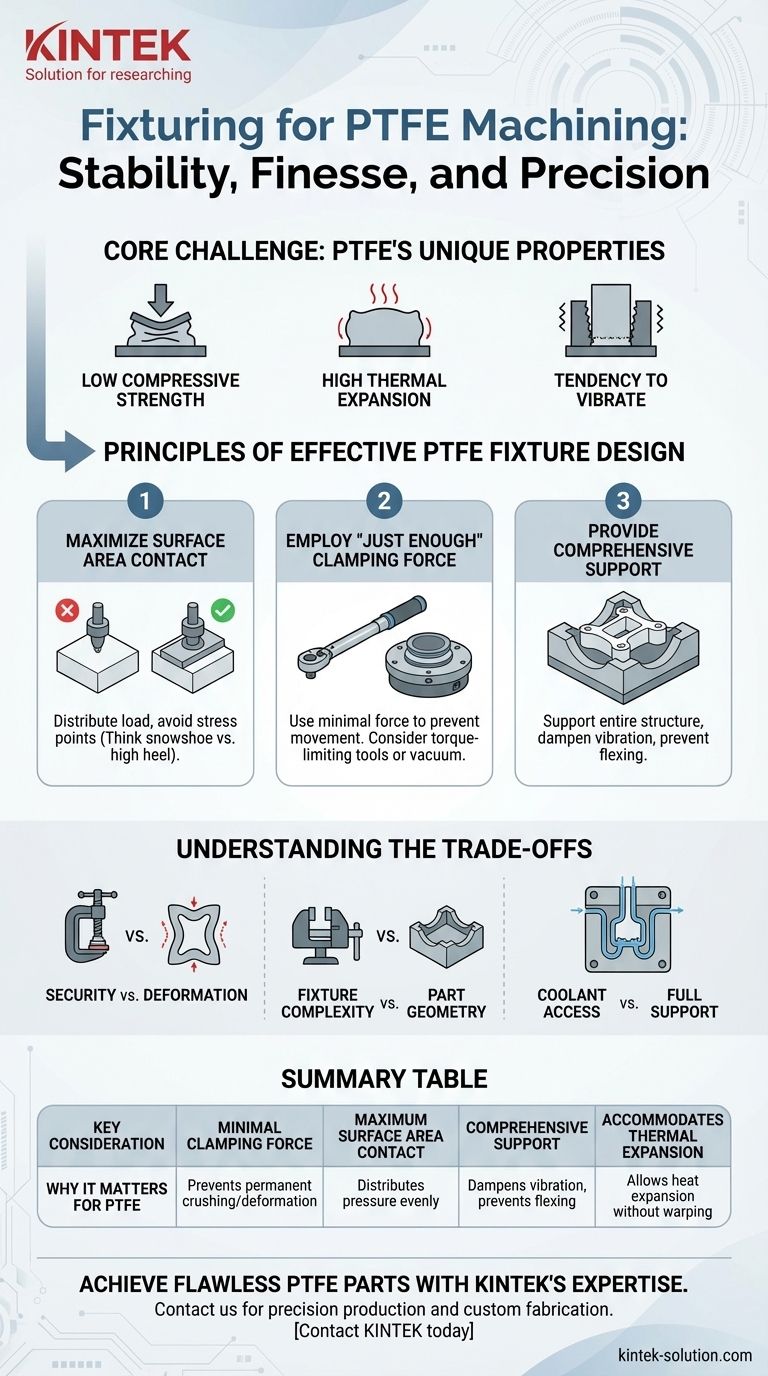

The Core Challenge: PTFE's Unique Properties

To design an effective fixture, you must first understand the material's behavior. PTFE is unlike metals or even most other plastics, and its properties directly dictate the fixturing strategy.

Low Compressive Strength

PTFE is incredibly soft and has poor "memory." Applying concentrated force, such as from standard vise jaws or pointed clamps, will easily deform or crush the material.

This deformation is often permanent, leading to out-of-spec parts an scrapped material.

High Thermal Expansion

PTFE expands and contracts with temperature changes far more than most materials. The friction from a cutting tool generates significant localized heat, causing the part to grow.

If a rigid fixture constrains this natural expansion, the material will buckle, warp, or bulge, destroying dimensional accuracy.

Tendency to Vibrate

The material's softness and low modulus of elasticity mean it can easily chatter or vibrate during cutting if not supported correctly.

This vibration leads to a poor surface finish, inaccurate dimensions, and can even cause the tool to "grab" the material.

Principles of Effective PTFE Fixture Design

A successful fixture treats the PTFE workpiece with finesse, guiding it through the machining process rather than forcing it into submission.

Maximize Surface Area Contact

Avoid sharp clamping points at all costs. Instead, use fixtures that distribute the load over the largest possible surface area.

Think of it like a snowshoe versus a high heel on snow. Wide, flat jaws, custom-machined soft jaws, or full-contact nests prevent the fixture from leaving marks or deforming the part.

Employ "Just Enough" Clamping Force

The goal is to use only the force necessary to prevent the workpiece from moving. Anything more is a liability.

Consider using torque-limiting wrenches for repeatable, minimal clamping pressure. For highly delicate parts, vacuum chucks can provide excellent stability with virtually no compressive force.

Provide Comprehensive Support

Your fixture should support the body of the part, not just the edges. For parts with thin walls or complex geometries, this is non-negotiable.

A custom-machined "nest" or cradle that matches the part's contour is the ideal solution. It supports the entire structure, dampening vibration and preventing any section from flexing under tool pressure.

Understanding the Trade-offs

Designing a fixture for PTFE involves balancing competing requirements. Recognizing these trade-offs is key to avoiding common pitfalls.

Security vs. Deformation

This is the central conflict in PTFE fixturing. The desire to ensure the part is secure can lead to over-tightening, which causes distortion.

The solution is always to prioritize better support over higher clamping force. If the part moves, the answer is not to clamp harder, but to improve how the fixture supports the entire workpiece.

Fixture Complexity vs. Part Geometry

A simple, blocky PTFE part may only require wide, parallel jaws. A delicate, thin-walled component will almost certainly require a custom-nested fixture.

Be prepared for fixture design and fabrication to be a significant part of the project's cost and timeline, especially when dealing with tight tolerances or complex shapes.

Coolant Access vs. Full Support

While full support is ideal, the fixture must not prevent coolant from reaching the cutting zone. Heat is a primary enemy of PTFE tolerance.

Design fixtures with channels or standoffs that allow for effective coolant flow while still providing the necessary stability. Pressurized air or water-soluble coolants are often used.

Making the Right Choice for Your Part

Your fixturing strategy should be tailored to the specific demands of the workpiece and the required tolerances.

- If your primary focus is machining robust, blocky parts: You can often succeed with high-quality machine vises using wide, soft jaws to distribute pressure evenly.

- If your primary focus is machining thin-walled or delicate parts: You must invest in custom fixtures like nests, cradles, or vacuum chucks to provide total support without distortion.

- If your primary focus is holding tight tolerances (+/- .001" per inch): Your fixture must be exceptionally stable and paired with sharp tooling, slow feed rates, and excellent temperature control.

Ultimately, a well-designed fixture is the foundation upon which all other aspects of successful PTFE machining are built.

Summary Table:

| Key Consideration | Why It Matters for PTFE |

|---|---|

| Minimal Clamping Force | Prevents permanent crushing and deformation of the soft material. |

| Maximum Surface Area Contact | Distributes pressure evenly, like a snowshoe, to avoid stress points. |

| Comprehensive Support | Dampens vibration and prevents flexing in thin-walled or complex parts. |

| Accommodates Thermal Expansion | Allows the part to expand with heat from machining without warping. |

Achieve Flawless PTFE Parts with KINTEK's Expertise

Machining PTFE to precise specifications requires a partner who understands the delicate balance of fixture design. At KINTEK, we specialize in manufacturing high-precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts are held with the perfect combination of stability and finesse, from prototype to high-volume production.

Let us put our precision production and custom fabrication experience to work for you. Contact KINTEK today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry