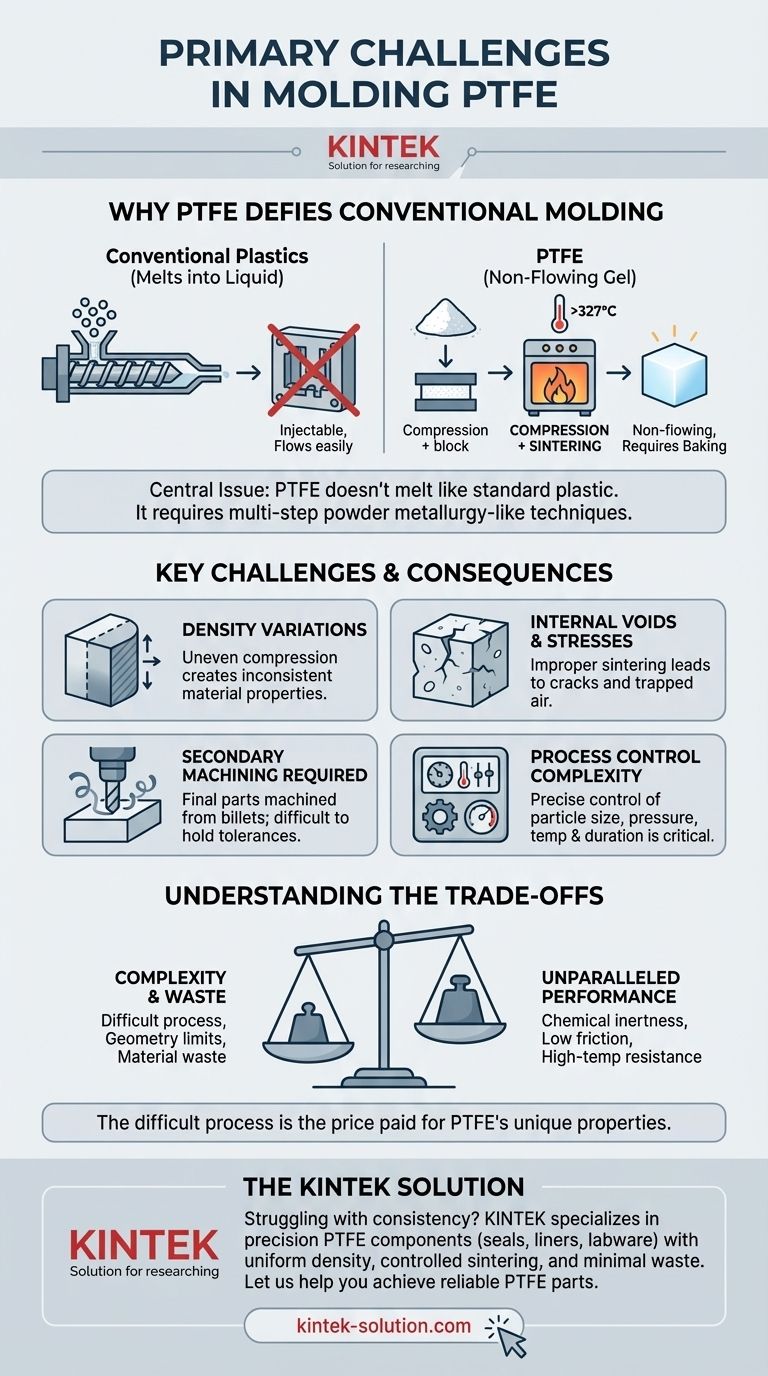

The primary challenges in molding Polytetrafluoroethylene (PTFE) stem from two core material properties: its extremely high melt viscosity and the requirement for a post-molding sintering process. Unlike conventional thermoplastics that melt into a liquid and can be injected into a mold, PTFE becomes a non-flowing gel, making it incompatible with standard injection molding and extrusion. This necessitates specialized, multi-step techniques more akin to powder metallurgy than plastics processing.

The central issue is that PTFE cannot be truly melted and molded in the traditional sense. Instead, its powdered form must be compressed into a shape and then baked in a high-temperature oven—a process called sintering—to fuse the particles together, which introduces significant challenges in achieving consistency and precision.

Why PTFE Defies Conventional Plastic Molding

To understand the manufacturing difficulties, you must first understand why PTFE behaves so differently from common plastics like polyethylene or nylon. Its unique molecular structure is the root cause of both its desirable properties and its processing challenges.

The Problem of Extreme Melt Viscosity

When heated past its melting point of approximately 327°C, PTFE does not become a low-viscosity, free-flowing liquid. Instead, it transitions into a translucent, highly viscous gel.

This gel is so thick that it cannot be forced through the narrow gates and channels of a standard injection mold. The pressure required would be astronomically high, and the material simply would not fill the cavity correctly.

The Necessity of Sintering

Because melt processing is not an option, PTFE is handled using a multi-step compression and sintering cycle.

First, the granular PTFE powder is compressed under high pressure (typically at room temperature) into a desired preform, such as a rod, tube, or sheet. This solid block is often called a "billet."

Second, this fragile preform is carefully heated in a precisely controlled oven to temperatures above its melting point. It is held at this temperature for a set period to allow the individual polymer particles to fuse, or sinter, into a solid, cohesive mass. This step is what provides the final part its mechanical strength.

The Impact on Process Control

This multi-step process is inherently more complex to control than a single-shot injection molding cycle.

The final properties of a PTFE part are heavily dependent on variables like the initial particle size of the powder, the compression pressure used, and the precise temperature and duration of the sintering cycle. Any deviation can significantly alter the final product's characteristics.

Common Quality and Consistency Challenges

The unique manufacturing process for PTFE directly leads to several well-known quality control issues that engineers and designers must anticipate.

Achieving Uniform Density

It is very difficult to apply compression pressure perfectly evenly throughout a large PTFE billet. The powder closer to the press surfaces gets compacted more than the material in the center.

This results in density variations throughout the preform. A part machined from the outside of a billet may have slightly different mechanical properties than a part machined from the core, which can be a critical issue for high-performance applications.

Managing Internal Voids and Stresses

The sintering process, if not managed perfectly, can create problems. If the preform is heated too quickly or cooled improperly, thermal stresses can build up, leading to internal cracks.

Furthermore, trapped air from the compression stage can create microscopic voids within the material, compromising its structural integrity and creating potential failure points.

The Secondary Challenge: Machinability

Because it is often molded into large, simple shapes (billets), the final intricate part is typically created through secondary CNC machining.

However, PTFE's softness and tendency for thermal expansion make it difficult to machine accurately. Using dull tools or incorrect cutting speeds can lead to burr formation, poor surface finishes, and a failure to hold tight tolerances.

Understanding the Trade-offs

The complex processing of PTFE is a direct trade-off for its exceptional performance characteristics. Understanding these compromises is key to using the material effectively.

Complexity vs. Performance

The difficult, multi-step manufacturing process is the price paid for PTFE's unparalleled chemical inertness, extremely low coefficient of friction, and high-temperature resistance. No other process can yield a part with these properties.

Limitations on Part Geometry

Compression molding and sintering are best suited for creating simple, robust shapes with thick walls. This process is not economical or practical for producing the small, highly complex, or thin-walled parts that are easily made with injection molding.

Material Waste and Cost

When a final part is machined from a larger billet, a significant amount of the expensive PTFE material is cut away as waste. This contrasts sharply with near-net-shape processes like injection molding, where material waste is minimal. This factor contributes significantly to the final cost of a PTFE component.

Making the Right Choice for Your Goal

To successfully manufacture a PTFE part, you must align the process with the design intent. Different end goals require different considerations.

- If your primary focus is simple, robust shapes (e.g., seals, rings, sheets): Standard compression molding followed by a well-controlled sintering cycle is the most effective and established method.

- If your primary focus is complex geometries with high precision: You must design for a two-stage process. First, mold a near-net-shape preform, and second, utilize precision CNC machining with sharp tooling as a critical finishing step.

- If your primary focus is high-volume production of small, intricate parts: You should investigate melt-processable fluoropolymers like FEP or PFA. These alternatives may offer a sufficient performance profile while being compatible with conventional injection molding.

Ultimately, successfully working with PTFE requires embracing its unique nature rather than fighting it.

Summary Table:

| Challenge | Description | Impact on Manufacturing |

|---|---|---|

| Extreme Melt Viscosity | PTFE becomes a non-flowing gel when heated, not a liquid | Cannot use standard injection molding; requires specialized compression techniques |

| Sintering Process | Requires high-temperature baking to fuse particles | Complex temperature control needed; risk of internal stresses and cracks |

| Density Variations | Uneven compression creates inconsistent material properties | Affects mechanical performance and part reliability |

| Secondary Machining | Soft material requires precision CNC finishing | Difficult to maintain tight tolerances; potential for burrs and waste |

Struggling with PTFE molding consistency? KINTEK specializes in overcoming these exact challenges. We manufacture precision PTFE components (seals, liners, labware, etc.) for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures uniform density, controlled sintering, and minimal waste. Let us help you achieve reliable PTFE parts with superior chemical resistance and performance. Contact KINTEK today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments