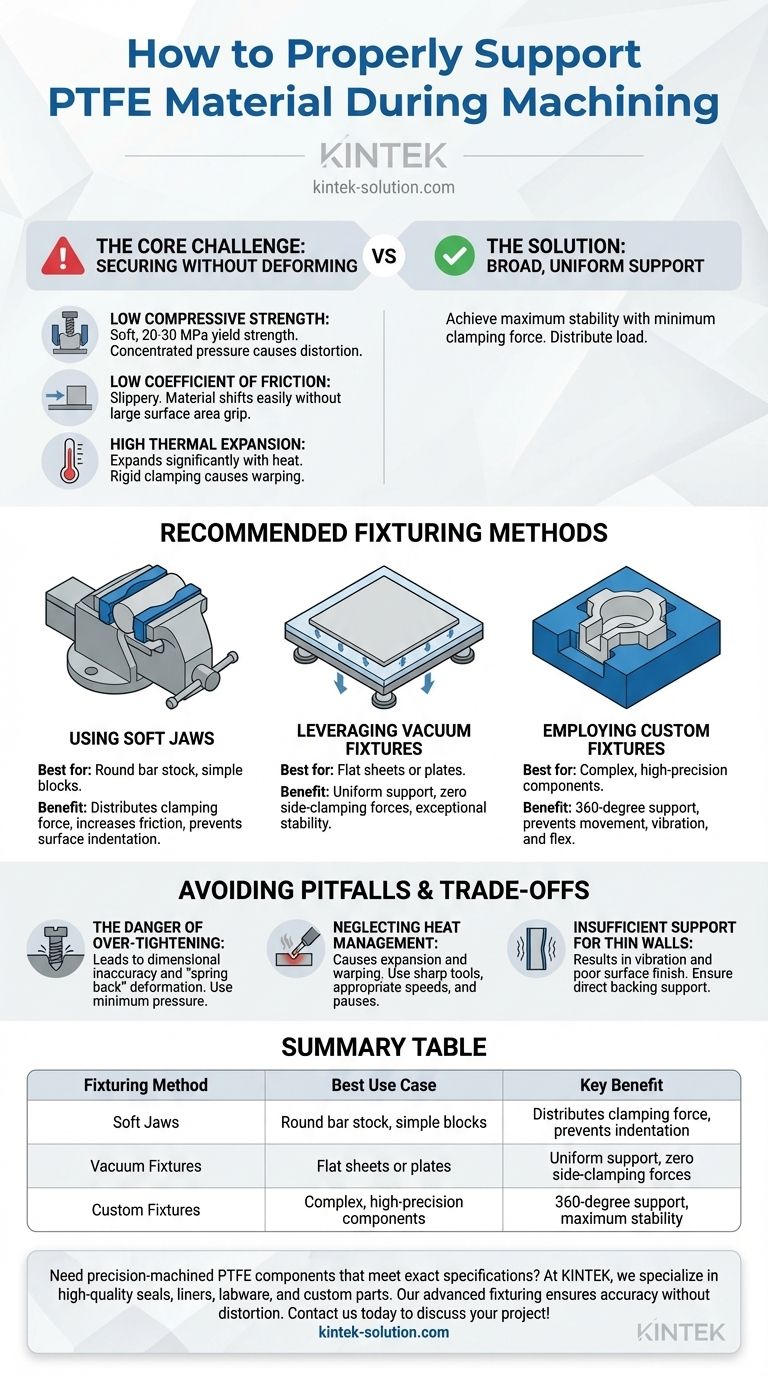

To properly support PTFE material during machining, you must use fixtures that provide broad, uniform support with minimal clamping pressure. Methods like soft jaws or precision vacuum fixtures are ideal because they hold the workpiece securely without causing the distortion or warping common with this soft, low-friction polymer.

The central challenge in machining Polytetrafluoroethylene (PTFE) is its inherent softness and slipperiness. Your support strategy must achieve maximum stability with the absolute minimum clamping force to prevent deforming the part and compromising dimensional accuracy.

The Core Challenge: Securing Without Deforming

Understanding PTFE's unique properties is the first step to machining it successfully. The material is defined by a combination of traits that make standard fixturing methods problematic.

Low Compressive Strength

PTFE is very soft and has a low yield strength, typically between 20–30 MPa. Applying concentrated clamping pressure, as you would with a standard vise, will easily crush, indent, or distort the material.

Low Coefficient of Friction

PTFE is famously slippery. This means it can easily shift or push out of a fixture if not held securely across a large surface area, especially under the lateral forces of a cutting tool.

High Thermal Expansion

The material expands and contracts significantly with temperature changes. Heat generated during cutting can cause the part to warp or bow, especially if it is rigidly clamped with no room for this thermal movement.

Recommended Fixturing Methods

The goal of any PTFE fixture is to distribute the clamping load over the largest possible surface area. This maximizes grip while minimizing pressure at any single point.

Using Soft Jaws

For parts held in a vise, soft jaws made from aluminum, nylon, or even another piece of plastic are highly effective. These jaws conform slightly to the part's shape, distributing the clamping force and increasing friction without marring the surface.

Leveraging Vacuum Fixtures

A precision vacuum fixture or vacuum table is often the best solution, particularly for flat sheets or plates. It holds the workpiece from below with uniform atmospheric pressure, providing exceptional stability with zero side-clamping forces that could cause distortion.

Employing Custom Fixtures

For complex or high-volume parts, a custom-machined or 3D-printed fixture that nests or cradles the entire component is ideal. This provides 360-degree support, ensuring the part cannot move, vibrate, or flex during the operation.

Understanding the Pitfalls and Trade-offs

Simply holding the material is not enough. Avoiding common mistakes is critical for achieving a high-quality finished part.

The Danger of Over-Tightening

The most common mistake is applying too much clamping force. This will invariably lead to a part that is dimensionally inaccurate once it is released from the fixture and "springs back" to a deformed state. Always use the minimum pressure required to prevent movement.

Neglecting Heat Management

Aggressive cuts generate heat, causing the PTFE to expand against the fixture. This induces internal stress and can lead to warping. Use sharp tools with a positive rake (0–15 degrees), appropriate cutting speeds (200–500 m/min), and consider periodic pauses to allow for cooling.

Insufficient Support for Thin Walls

Thin or delicate sections of a part can easily vibrate or deflect away from the cutting tool, resulting in a poor surface finish and incorrect dimensions. Ensure your fixturing provides direct support behind any thin walls being machined. Using circular or helical toolpaths can also help minimize stress on these features.

Making the Right Choice for Your Goal

Your fixturing strategy should adapt to the geometry of your part and your desired outcome.

- If your primary focus is machining flat sheets or plates: A vacuum fixture is the superior choice, providing the most uniform support with the lowest risk of distortion.

- If your primary focus is working with round bar stock or simple blocks: Use a vise with custom-machined soft jaws or a low-pressure collet to distribute the clamping force evenly.

- If your primary focus is producing complex, high-precision components: Invest the time in creating a custom fixture that fully nests the part to guarantee stability and dimensional accuracy.

Mastering the delicate balance of support and pressure is the key to producing accurate, high-quality PTFE components.

Summary Table:

| Fixturing Method | Best Use Case | Key Benefit |

|---|---|---|

| Soft Jaws | Round bar stock, simple blocks | Distributes clamping force, prevents indentation |

| Vacuum Fixtures | Flat sheets or plates | Uniform support, zero side-clamping forces |

| Custom Fixtures | Complex, high-precision components | 360-degree support, maximum stability |

Need precision-machined PTFE components that meet exact specifications? At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, labware, and custom parts for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in advanced fixturing techniques ensures your parts are machined accurately, without distortion. From prototypes to high-volume orders, we deliver the precision you require. Contact us today to discuss your project!

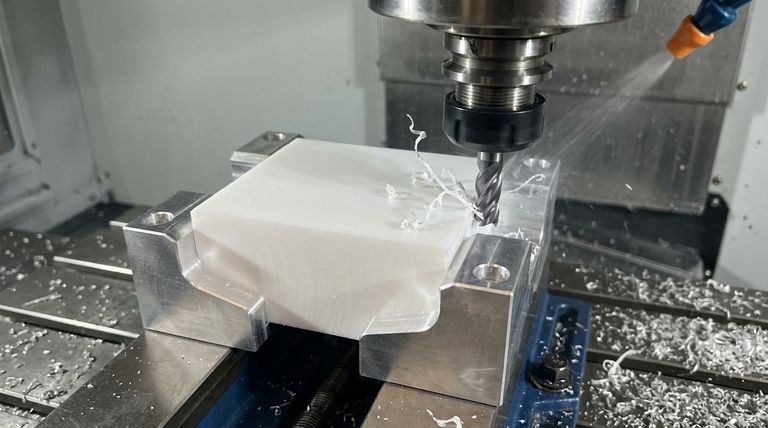

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency