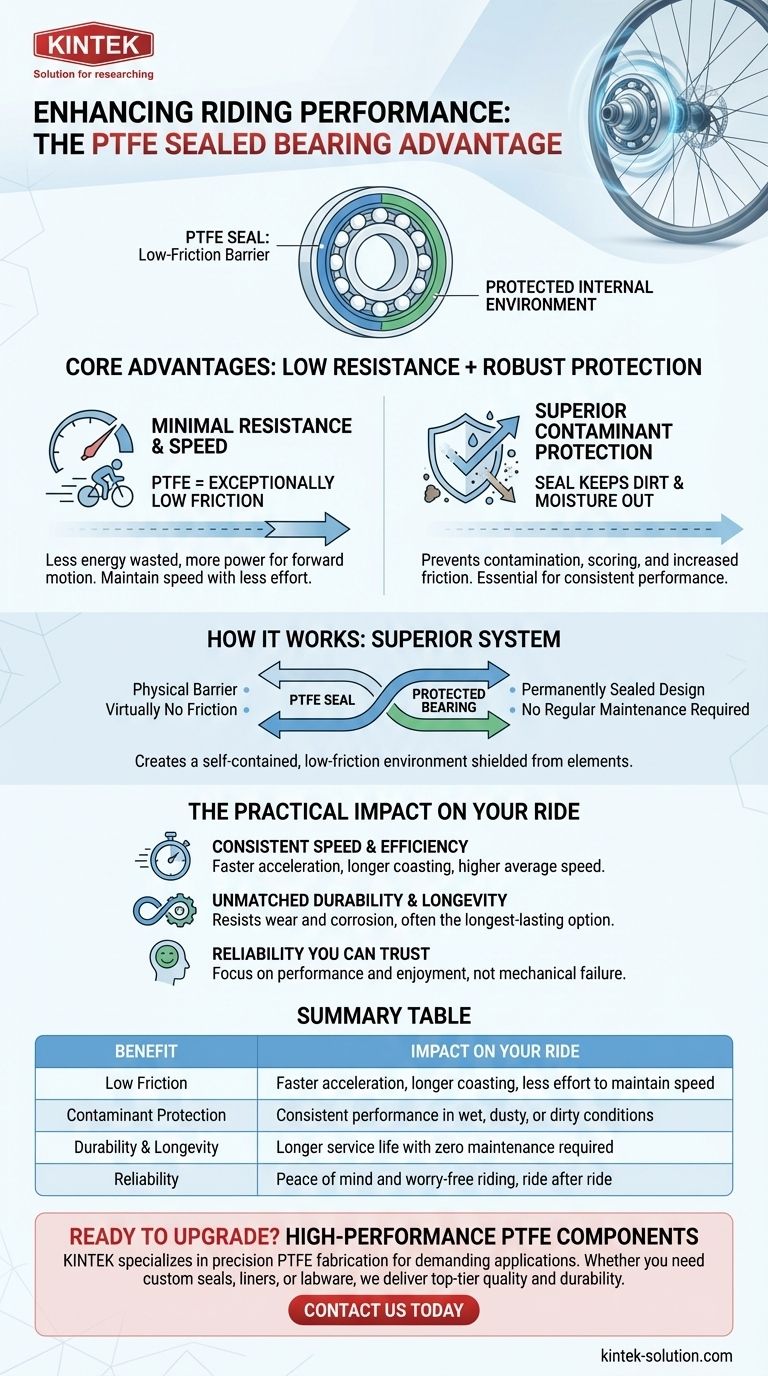

At their core, PTFE sealed ball bearings enhance riding performance by delivering a powerful combination of exceptionally low resistance and robust protection against contamination. This dual advantage ensures your wheels spin faster and longer, not just on the first ride, but consistently over time in real-world conditions.

The true benefit of PTFE sealed bearings isn't just about achieving maximum speed; it's about maintaining that speed reliably by creating a self-contained, low-friction environment that is shielded from performance-degrading elements like dirt and moisture.

Deconstructing the Performance Gains

To understand the impact of PTFE sealed bearings, we need to look at the two fundamental problems they solve: internal friction and external contamination.

The Critical Role of Low Resistance

Polytetrafluoroethylene, or PTFE, is known for having one of the lowest coefficients of friction of any solid. It creates an incredibly slick surface.

When used in bearing seals, this property minimizes the rotational drag that consumes your energy. Less energy wasted on friction means more power is translated directly into forward motion, allowing you to maintain speed with less effort.

The Imperative of Sealing

A ball bearing's worst enemies are dirt, dust, and moisture. Even microscopic particles can contaminate the lubricant, score the bearing races, and dramatically increase friction.

A proper seal acts as a barrier, protecting the pristine, lubricated environment inside the bearing from the harsh conditions outside. Without an effective seal, a bearing's performance degrades rapidly.

How PTFE Seals Create a Superior System

PTFE seals combine these two principles. They provide an excellent physical barrier to keep contaminants out while adding virtually no friction themselves.

Because they are so effective, they are often used in "permanently sealed" designs. The system is so well-protected that it doesn't require the regular cleaning and re-lubrication that other bearing types demand.

The Practical Impact on Your Ride

These technical advantages translate directly into a better, more reliable riding experience.

Consistent Speed and Efficiency

With minimal resistance and protection from contamination, your wheels spin more freely. This results in faster acceleration, longer coasting distances, and a higher average speed over the course of a ride.

Unmatched Durability and Longevity

By preventing the ingress of dirt and water, PTFE sealed bearings are often the longest-lasting bearings available. They resist the wear and corrosion that cause other bearings to fail prematurely, saving you time and money on replacements.

Reliability You Can Trust

Perhaps the most significant benefit is peace of mind. Riders can focus on their performance, technique, and enjoyment without worrying about a gritty or seized bearing ruining a ride or a race.

Understanding the Trade-offs

While highly effective, it's important to understand the context and potential limitations of this technology.

The "Maintenance-Free" Reality

"Permanently sealed" means the bearing is not designed to be user-serviceable. This is a major advantage for those who want a "fit and forget" component.

However, if you are a user who prefers to meticulously clean and re-lube your bearings with custom lubricants, this design may feel restrictive. When a permanently sealed bearing eventually wears out, it is replaced, not serviced.

Cost vs. Long-Term Value

High-quality PTFE sealed bearings typically carry a higher upfront cost than standard rubber-sealed or unsealed bearings.

The decision comes down to weighing that initial investment against the long-term benefits of superior durability, zero maintenance time, and consistently high performance in all conditions.

Making the Right Choice for Your Goal

The right bearing is the one that aligns with your specific needs and riding environment.

- If your primary focus is maximum durability and minimal maintenance: PTFE sealed bearings are the definitive choice, especially for riding in wet, dusty, or unpredictable conditions.

- If your primary focus is absolute peak performance in a clean, controlled environment (like an indoor track): You might consider lightly-sealed or unsealed bearings, but you must accept the trade-off of constant, meticulous maintenance.

- If your primary focus is balancing cost and performance: Standard rubber-sealed bearings offer good protection for general use but lack the elite longevity and low friction of a PTFE system.

Ultimately, choosing PTFE sealed bearings is an investment in consistent, worry-free performance for the long haul.

Summary Table:

| Benefit | Impact on Your Ride |

|---|---|

| Low Friction | Faster acceleration, longer coasting, less effort to maintain speed |

| Contaminant Protection | Consistent performance in wet, dusty, or dirty conditions |

| Durability & Longevity | Longer service life with zero maintenance required |

| Reliability | Peace of mind and worry-free riding, ride after ride |

Ready to upgrade your equipment with high-performance PTFE components?

At KINTEK, we specialize in precision PTFE fabrication for demanding applications. Whether you need custom PTFE seals, liners, or labware for the semiconductor, medical, laboratory, or industrial sectors, we deliver the same commitment to quality and durability that defines top-tier PTFE bearings.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts