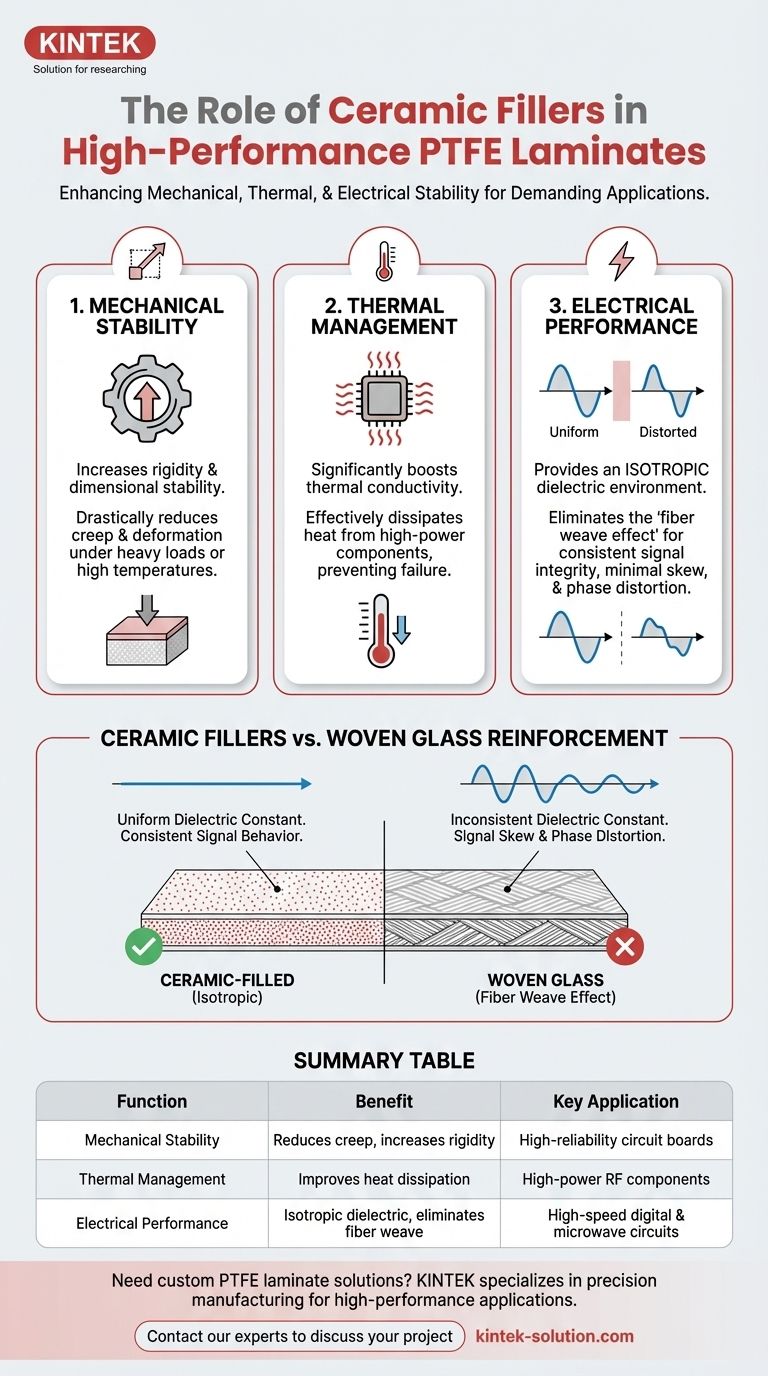

In short, ceramic fillers are added to PTFE laminates to precisely engineer their mechanical, thermal, and electrical properties for high-performance applications. By dispersing fine ceramic particles throughout the PTFE matrix, manufacturers can create a composite material that overcomes many of the limitations of both pure PTFE and traditional glass-reinforced laminates.

The central purpose of using ceramic fillers is to enhance the thermal and mechanical stability of PTFE without introducing the negative electrical side effects, such as signal skew and phase inconsistency, that are common with woven glass fiber reinforcements.

The Core Functions of Ceramic Fillers

Adding ceramic particles to a PTFE base fundamentally changes the material's behavior. This allows for a high degree of customization to meet specific engineering challenges, particularly in high-frequency electronics.

Enhancing Mechanical Stability

Pure PTFE can be prone to creep, which is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

Ceramic fillers add significant rigidity to the material, drastically reducing creep and deformation under heavy loads or at elevated temperatures. This results in a circuit board that is more dimensionally stable during fabrication and throughout its service life.

Improving Thermal Management

High-power RF components generate significant heat, and managing this heat is critical for reliability. Pure PTFE has relatively low thermal conductivity.

Ceramic fillers significantly increase the laminate's ability to conduct heat away from active components. This improved thermal management helps prevent component failure and ensures more consistent performance.

Optimizing Electrical Performance

This is the most critical benefit for high-speed digital and RF/microwave applications. Traditional laminates use woven glass for reinforcement, but this creates an inconsistent dielectric environment.

Ceramic-filled PTFE provides a more uniform or isotropic electrical environment. Because the ceramic particles are distributed evenly rather than in a weave pattern, the material's dielectric constant remains consistent, which is crucial for signal integrity.

Ceramic Fillers vs. Woven Glass Reinforcement

The choice between a ceramic-filled or glass-reinforced PTFE laminate hinges on the demands of the application, especially electrical performance.

The Problem with Woven Glass

A woven glass fabric creates a non-uniform structure. A signal trace running over a bundle of glass fibers experiences a different dielectric constant than a trace running over the PTFE-rich space between bundles.

This inconsistency is known as the fiber weave effect. It can cause signals traveling on parallel traces to arrive at different times (skew) and can distort the signal's phase, degrading the performance of sensitive circuits.

The Ceramic Solution: Isotropic Performance

Ceramic fillers, being particulate, are randomly and homogeneously dispersed. They do not have a weave structure.

This creates a material that is electrically consistent in all directions. It eliminates the fiber weave effect, ensuring predictable signal behavior and preserving the integrity of high-frequency signals.

Understanding the Trade-offs

While highly effective, ceramic-filled materials are not a universal solution. It's important to understand the associated considerations.

The 'Reinforced' vs. 'Filled' Distinction

Vendors may use the terms 'ceramic-reinforced' and 'ceramic-filled' interchangeably. However, a true 'filled' material uses particulate fillers, whereas some 'reinforced' materials might still contain a woven structure.

If eliminating fiber weave effect is your primary goal, it is critical to verify the material's internal structure from the manufacturer's datasheet.

Potential Impact on Other Properties

As a general rule, adding any filler can slightly alter some of the base material's inherent properties. While ceramics are chosen for their stability, it is always wise to confirm that properties like chemical resistance still meet your specific application's requirements.

Cost and Processing

Ceramic-filled PTFE laminates are specialized materials engineered for high performance. They are often more expensive than standard glass-reinforced alternatives like FR-4 or even some woven-glass PTFE products.

Making the Right Choice for Your Application

Selecting the correct laminate is a crucial design decision based on balancing performance requirements with cost.

- If your primary focus is high-frequency signal integrity: Choose a ceramic-filled PTFE laminate to eliminate fiber weave effects, ensuring minimal signal skew and phase distortion.

- If your primary focus is thermal management for high-power components: The superior thermal conductivity of ceramic-filled PTFE makes it the ideal choice for dissipating heat effectively.

- If your primary focus is mechanical rigidity at a lower cost: A traditional woven glass-reinforced PTFE may be sufficient, provided your application can tolerate minor electrical inconsistencies.

Ultimately, choosing a ceramic-filled PTFE laminate is a deliberate engineering decision to achieve superior and more predictable performance in demanding electronic systems.

Summary Table:

| Function | Benefit | Key Application |

|---|---|---|

| Mechanical Stability | Reduces creep, increases rigidity | High-reliability circuit boards |

| Thermal Management | Improves heat dissipation | High-power RF components |

| Electrical Performance | Provides isotropic dielectric constant, eliminates fiber weave effect | High-speed digital & microwave circuits |

Need a custom PTFE laminate solution for your demanding application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom formulations for the semiconductor, medical, and laboratory industries. Our expertise in material science allows us to help you select or develop the ideal ceramic-filled PTFE laminate to meet your specific requirements for signal integrity, thermal management, and mechanical stability—from prototypes to high-volume production.

Contact our experts today to discuss your project and discover how we can enhance your product's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support