At its core, machined PTFE is used to create a vast range of components where chemical resistance, low friction, or high-temperature stability are critical. The most common parts include seals, gaskets, bearings, bushings, valve seats, and electrical insulators. These components are fundamental across demanding industries like aerospace, medical, electronics, and chemical processing.

The common thread connecting all machined PTFE parts is not mechanical strength, but a trio of elite properties: near-universal chemical resistance, an extremely low coefficient of friction, and high-temperature stability. These characteristics make it the material of choice for components that must slide, seal, or insulate in harsh environments.

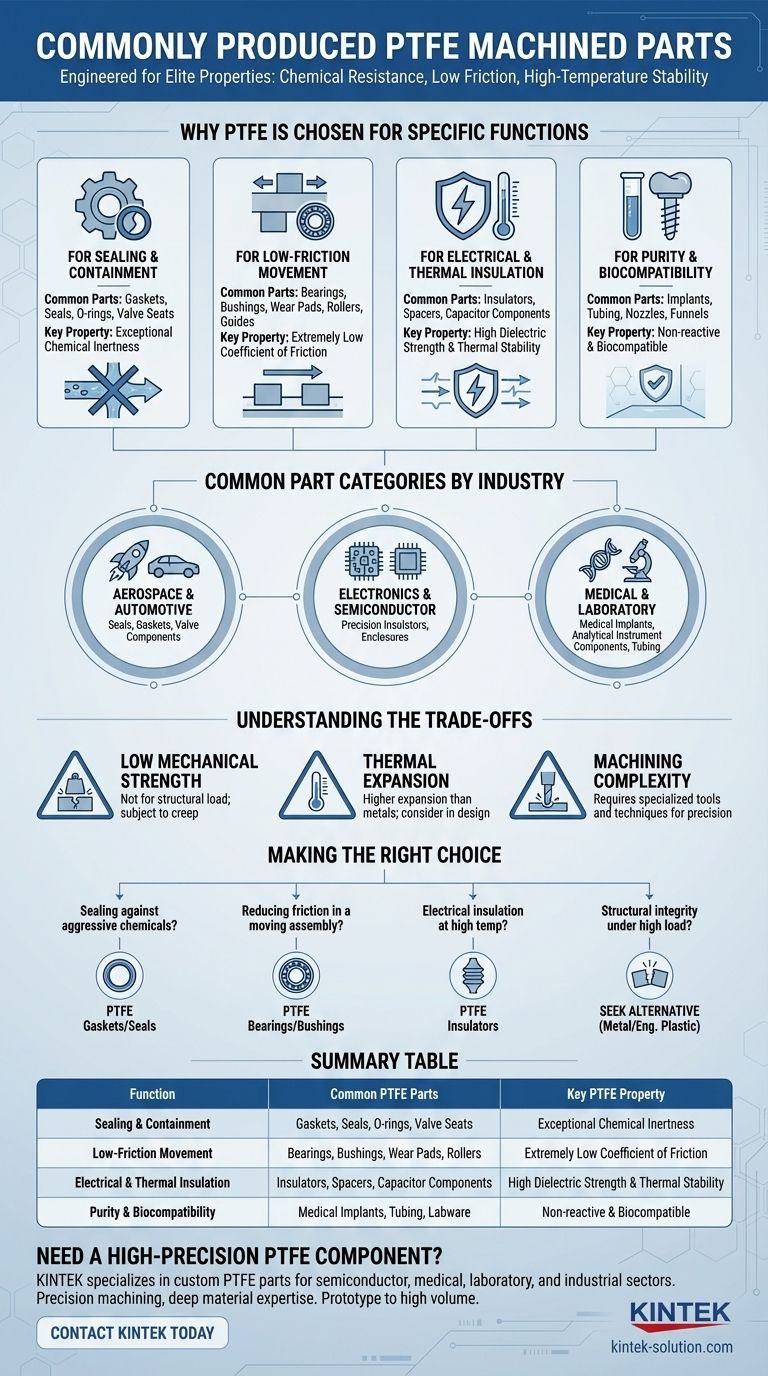

Why PTFE Is Chosen for Specific Functions

The diverse list of PTFE parts can be understood by grouping them by their primary function. The material's unique properties make it a specialist, solving problems that commodity plastics cannot.

For Sealing and Containment

Parts like gaskets, seals, O-rings, and valve seats are frequently machined from PTFE.

Its primary advantage here is exceptional chemical inertness. PTFE can withstand nearly all industrial chemicals and solvents, ensuring the integrity of a seal even when exposed to highly corrosive substances.

For Low-Friction Movement

PTFE is the standard for parts that slide against each other, such as bearings, bushings, wear pads, rollers, and guides.

This is due to PTFE having one of the lowest coefficients of friction of any solid material. It acts as a solid lubricant, reducing wear and energy consumption in mechanical systems without the need for external oils or greases.

For Electrical and Thermal Insulation

In the electronics and semiconductor industries, PTFE is used for insulators, spacers, and components for capacitors.

PTFE is an excellent electrical insulator with high dielectric strength and can maintain this property over a wide range of temperatures. This stability is crucial for performance and reliability in electronic devices.

For Purity and Biocompatibility

The medical and laboratory fields use PTFE for implants, tubing, nozzles, and funnels.

Its non-reactive nature and biocompatibility mean it will not trigger an immune response in the body or contaminate sensitive samples in a lab, making it ideal for high-purity applications.

Common Part Categories by Industry

While many parts are used across multiple sectors, certain industries rely heavily on specific PTFE components.

Aerospace and Automotive

These industries use PTFE for seals, gaskets, and valve components that must perform reliably under extreme temperatures and exposure to fuels and hydraulic fluids.

Electronics and Semiconductor

Key parts include precision-machined insulators, semiconductor components, and enclosures. The material's purity and dielectric properties are non-negotiable in these applications.

Medical and Laboratory

Commonly produced parts are medical implants, analytical instrument components, and tubing. Biocompatibility and chemical inertness are the driving factors for its selection.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Understanding its limitations is critical for proper application.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for structural components that must bear significant mechanical loads, as it can deform under pressure, a phenomenon known as "creep."

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. This must be accounted for in designs where parts are subject to wide temperature fluctuations to maintain tight tolerances.

Machining Complexity

Although machinable, the softness of PTFE requires specialized tools and techniques. This is necessary to achieve high precision without causing the material to deform or "smear" during the cutting process.

Making the Right Choice for Your Application

Your final decision should be driven entirely by the primary challenge you need to solve.

- If your primary focus is sealing against aggressive chemicals: PTFE's near-universal chemical inertness makes it the default choice for gaskets and seals.

- If your primary focus is reducing friction in a moving assembly: Its exceptionally low coefficient of friction makes it ideal for bearings, bushings, and wear pads.

- If your primary focus is electrical insulation in a high-temperature environment: PTFE's dielectric properties and thermal stability are superior to most other polymers.

- If your primary focus is structural integrity under high load: You should seek an alternative engineering plastic or metal, as PTFE's softness makes it unsuitable for this role.

Ultimately, selecting PTFE is a strategic decision to solve problems of friction, corrosion, or insulation where other materials consistently fail.

Summary Table:

| Function | Common PTFE Parts | Key PTFE Property |

|---|---|---|

| Sealing & Containment | Gaskets, Seals, O-rings, Valve Seats | Exceptional Chemical Inertness |

| Low-Friction Movement | Bearings, Bushings, Wear Pads, Rollers | Extremely Low Coefficient of Friction |

| Electrical & Thermal Insulation | Insulators, Spacers, Capacitor Components | High Dielectric Strength & Thermal Stability |

| Purity & Biocompatibility | Medical Implants, Tubing, Labware | Non-reactive & Biocompatible |

Need a high-precision PTFE component for your application?

KINTEK specializes in manufacturing custom PTFE parts—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine precision machining with deep material expertise to deliver components that excel in harsh chemical, high-temperature, or high-purity environments.

Whether you require a prototype or a high-volume order, we ensure your parts meet the exacting standards your industry demands.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance